Decorative sheets for wall decoration. How to choose decorative panels for interior wall decoration: interesting varieties, types of materials and installation nuances

It is not enough to build a new house - interior decoration is an equally important and crucial stage. It is the decoration that makes a standard dwelling a unique, warm and comfortable home, so manufacturers are always in search of new materials.

Wall panels for interior decoration have been on the market not so long ago, but have already confidently occupied their niche and are becoming more and more popular and in demand over time. Panels are chosen not only for significantly facilitating the repair process, but also for a variety of colors and shapes, which allows you to create your own, original interior style.

Pick up Wall panels can fit any interior with any color scheme

Types of wall panels for interior decoration

Wall cladding with panels helps to make repairs quickly, get excellent results and save a lot on the cost of repairs. After all, they can cover the lack of plaster, uneven corners and other possible construction flaws. With an abundance of choice, it is not easy to decide which materials to use. Let's see what types and why are the most interesting today, what to give preference to.

Slatted panels

Such panels are used for decoration of any premises, except, perhaps, for children. The length of the slats ranges from 2.4 to 3.6 m, the width is from 12.5 to 30 cm, the thickness of the slats is 8-12 mm. They can be white or colored, imitate various breeds tree. Indispensable for rooms with a small area and many corners. Slatted panels easily cover internal and external corners. To connect the rails to each other, spikes or grooves are used. To make the joints invisible, manufacturers offer a huge number of corners, plugs, skirting boards and other products that make installation simple and neat, with minimal experience, you can do it yourself.

When installing plastic wall panels for interior decoration, plugs and corners will hide the seams and complement the overall picture, if chosen correctly

Rack wall panels made of wood are called "lining" and are actively used. They can be covered with stain or varnish, or simply painted, creating an unusual interior. Often the lining is given the effect of an aged tree. AT recent times the popularity of the "lining" has declined slightly, giving way to more modern materials, but cottages, summer kitchens and loggias are finished with this type of cladding.

leafy

This kind is different large sizes. But, it allows you to quickly mount panels over a large area. Sheets 122x244 cm and 6 mm thick are made of multilayer fiberboard with a variety of impregnation or PVC. Often they imitate stone, wood and are attached to the wall with glue. They are light, durable, you can not do a crate for their installation.

Imitation of brick or stone in wall panels for interior decoration - always look original

Tiled

Facing with tiled panels allows you to give the walls volume, get relief images, with their help you can create an absolutely unique interior. Lock connections allow you to get from small-sized plates (90x90 cm, 30x30 cm) wall coverings large area. They imitate expensive breeds tree or a natural stone. Often they decorate living rooms and fireplace areas with them.

Wooden panels for interior wall decoration from different "wood species"

What materials are made from

Decorative wall panels are made of chipboard, fiberboard, MDF or PVC.

Today, new materials for their manufacture appear almost every day. Stone chips appeared, glass panels also find their admirers. What material to choose, you can decide only with the right information.

On our website you can find contacts of construction companies that offer. You can directly communicate with representatives by visiting the exhibition of houses "Low-Rise Country".

Wood

For the manufacture of cladding, wood has been used for a very long time. Initially, such panels were made of solid wood, were expensive and inaccessible to most buyers. Today you can buy combined wood panels, the cost of which is much lower. The front layer of such products is valuable varieties of wood applied to a pine or spruce base. The development of technology has made it possible to produce such finishing materials. High Quality from waste woodworking industry (sawdust, wood chips). This made it possible to finish the walls in the rooms imitating expensive wood species, very budget. Wall panels under a tree are pertinent in any interior. However, natural wood cladding has not lost its relevance and is able to favorably emphasize the status of the owner of the premises.

Panels for interior decoration with natural wood veneer always look expensive

Chipboard and fiberboard

Enough cheap material. Chipboard and fiberboard, as these well-known abbreviations are deciphered, can add warmth and sound insulation to the room, decorate it, however, the high content of formaldehyde resins in the boards, the unstable outer coating and the rapid deformation from moisture and steam have greatly reduced the popularity of this material for finishes recently.

Chipboard and fiberboard are more often used to level walls for finishing

MDF

This is a more modern improved version of chipboard. It is sometimes erroneously referred to as modified plywood. The first to produce this material was Medium Density Fibreboard. The first three letters formed its name Instead of formaldehyde resins, vegetable lignin is used in production. MDF panels are more durable, they better withstand high humidity. Have a very long term services are easy to maintain and do not emit harmful compounds into the air.

Panels can be lacquered, often veneered with precious woods, laminated or coated with water-repellent compounds. The material can withstand heavy loads, you can safely attach heavy objects to them, such as paintings or bookshelves. Today, such panels are used more often for decoration. office space, in home decoration, I want something more refined and at the same time cozy.

MDF panels are more common in office spaces

PVC panels

Most cheap way room finishing. Any hardware store can offer huge selection similar finishing materials. Bright, with different patterns, imitating wood and plain, they are not afraid of dampness. They are often used in kitchens and bathrooms. The quality of PVC panels offered to the consumer has also improved significantly. Today, they do not fade; better quality plastic is used in the manufacture. When choosing, it is better to give preference to Russian or European manufacturers.

The disadvantage is that the abundance of plastic in the house can increase the humidity in it, for finishing living rooms(living room, nursery, bedroom), it is better to use more environmentally friendly and natural materials.

Partial finish PVC panels also looks nice

3D panels

This type of finish is at the peak of popularity today. Volumetric mosaic created from different materials (wood, glass, gypsum, plastic) allows you to add sophistication to the room. At the same time, the materials for the manufacture of panels can be absolutely natural, they do not cause allergies, they are easy to clean and retain their original appearance for a long time.

Your renovation will look fresh and neat in a few years. They look great in the bedroom and in the living room, they will create a voluminous fairy tale in your child's room. Do not deform and are not afraid of dampness. Easy to assemble, you can choose the finish in a suitable price category. Perfectly fit into any room, with their help a variety of interior styles are created.

3D gypsum panels have their own zest

Advantages and disadvantages of wall paneling

Wall decoration with wall panels has several advantages, you should pay attention to them when planning repairs:

- easy and quick to install;

- there is no need for costly leveling of walls, plastering, laborious removal of corners, they will hide all the problems of the walls;

- durable and easy to use;

- give full scope for imagination and unexpected design solutions;

- increase heat and sound insulation in the room;

- easy to wash;

- cables are perfectly hidden under them, of which there are many in our homes.

There is only one drawback, when they are mounted on the crate, the area of \u200b\u200bthe room decreases. If in large rooms this is not noticeable, then for rooms with a small area, it can be a problem.

When installing gypsum vinyl panels for walls for interior decoration, up to 5 cm can be lost from each wall

What to consider when choosing

The most important thing when choosing wall panels is that they must comply with sanitary standards and not be fire hazardous.

Toxicity, flammability, smoke level must be indicated on the label. The value is from 1 to 4, the higher it is, the worse the quality of the product.

When planning a renovation, decide which panels you want to see in your home. Do they have any other function besides decorative, is the environmental friendliness of the material from which the panels are made important to you and, finally, how much are you willing to pay for them. For example, glass decorative panels in the kitchen should not only decorate the room, but also protect the wall above the stove from grease and steam.

Video description

An example of stone veneer panels in the video:

For children, choose natural materials. The room in which the baby spends most of the time should be safe.

Do not take the cheapest panels. Their service life is not one year, let them be beautiful and of high quality, so that the results of the repair are a pleasure. When buying, carefully consider the appearance, chips and cracks should not be. Choose materials from the same batch to avoid color differences. Various types of wall panels for interior decoration allow you not to limit yourself in your choice.

The choice of color and material allows you to run wild fantasies

About fastening features

The next thing to pay attention to is how the panels are supposed to be attached to the wall. You can fix it with glue, or assemble a crate to which individual parts will be mounted.

Lathing - a special design of wooden bars or a metal profile. Fastened to the wall with dowels and is the basis for fixing wall panels.

If the room is damp and cold, it is better to stop at aluminum profiles. Wooden structure in such conditions quickly becomes unusable. For dry and warm rooms, the crate is made of wood.

Plastic and slatted panels for interior wall cladding are fastened together using a tongue-and-groove locking connection.

A wooden crate is being erected, panels are attached to its planks with the help of clamps (the so-called special staples). Sometimes parquet nails or self-tapping screws are used for fastening.

Fastening panels "groove-groove". To join the panels, special plastic or metal profiles are used, which, after installation, perform a decorative function.

Slots when docking "groove-groove", even if they are noticeable, look neat

When docking "groove-groove", the gaps between the materials are almost invisible

If the wall is flat, and it is supposed to be lined with soft panels made of fabric or leather, glue can be used. Usually, “liquid nails” are used for installation. At the next repair, cleaning the walls in this case may require additional efforts. It will have to be levelled. Light sheet wall panels for interior decoration can also be mounted on glue.

Important! panels can only be glued to perfectly flat walls.

Video description

Beautiful wall panels on video:

Conclusion

Installing wall panels eliminates many unpleasant moments. No need to get rid of old plaster or paint. To finish the walls and pay huge money for this work. Panels are mounted quickly, under them you can hide various wires, which are many in modern apartments. This type of cladding greatly simplifies life, facilitates cleaning and adds beauty and originality to your home.

If you are tired of the familiar atmosphere in your home, then the most The best way change the interior with little blood - use a new one. A great solution for a small update of the interior - decorative panels for interior wall decoration. Many people like this material, thanks to undemanding care, strength and resistance to mechanical stress. You can choose panels for every taste. So, we invite you to familiarize yourself with, find out how they can be advantageously used in the interior and study the nuances of installation.

What are decorative panels for interior wall decoration: nuances of application in the interior and advantages

With the help of decorative panels you can solve many problems in the design of your interior. They can help disguise unsightly wires, hide uneven walls, and help insulate and deal with your home.

You can use wall panels for interior decoration as. The material will help change the structure of the walls and make the interior more original.

To create luxurious interior in a classic style, it is not necessary to purchase expensive materials - you can choose panels of an unusual shape

To create luxurious interior in a classic style, it is not necessary to purchase expensive materials - you can choose panels of an unusual shape Here are some ways to use this material:

- sheathing the lower or upper part of the wall will create the desired accent;

- application finishing panels for interior decoration as an exquisite wall decor;

- combination of panels and;

- panels can be applied to the entire wall. Products made from natural material are suitable for cladding, billiard or;

- panels of different materials are used to give the interior an unusual effect.

Do you know that the fashion for such panels came to us in the 18th century from Europe. Such material was used to decorate interiors in the time of Catherine II. AT Soviet times decoration was used to decorate administrative buildings.

Currently, the use of panels for interior wall decoration is a rational and economical solution.

How the decorative panels look can be seen in the video:

Let's look at the main advantages of using such a material:

- Ease of use. Ease of maintenance and installation work;

- Security. Environmentally friendly materials are used for manufacturing;

- Durability. With proper installation and care, it can last for many years;

- A large assortment. You can purchase products from different materials, different textures and;

- Versatility. They allow not only to decorate the interior, but are also responsible for heat-insulating and sound-proofing qualities.

Consider the cons:

- Adaptation to conditions. Before applying the panels, they must be left in the room where the repair will be carried out. This will allow you to understand how the material will behave in the future;

- fragility. Some materials require careful handling during assembly and transport;

- Reduce space. They can “eat up” a significant area of \u200b\u200bthe room;

- Harm artificial materials . Some materials may present a hazard when heated.

Note! Using material of various textures will create a slight accent or emphasize the integrity of the style. With their help, you can realize any design idea.

Materials and types of wall panels for interior decoration

There are different types of wall panels, for the manufacture of which various materials are used. It is worth noting three main forms of panels:

- rack and pinion look like a wagon. They are fastened with clamps or staples for fastening. On the sides there are special spikes with which they are connected to each other. Suitable for use in any space. Placement in the vertical direction allows you to raise the ceilings;

- tile products look like square. They have the same fastening as rack and pinion. They can be laid out in the form of mosaics and patterns. At the same time, tiles with different textures and images are combined;

- ease of attachment differ options sheet wall panels for interior decoration. They are fixed with acrylic glue and nails. Their surfaces can imitate a variety of textures - wood, cork or stone. Such plates are used to decorate rooms with a large area.

Also, the material is classified according to the materials of manufacture:

- natural wood panels may have a different pattern and factor;

- PVC products come in a solid color palette or with patterns;

- synthetic fiber foam is soundproof. Such panels are additionally decorated with plastic;

- perfectly absorb sound and are environmentally friendly;

- material from MDF, chipboard or fiberboard;

- 3D products are volumetric plates that are made from different materials;

- gypsum boards They are a base of gypsum, which is covered on both sides with vinyl.

Note! You can combine tiles of different textures and color palettes to create original interiors.

Using wood panels for interior wall decoration

Wooden wall panels are popular due to their unusual texture. It is wood that can become a real decoration of any interior, as it gives the design elegance, presentability and nobility. For finishing, products are selected from arrays of valuable species, for example, rosewood, teak or.

The combination of a natural shade and a mirror insert or gilded carving looks good.

Wall panels made of wood can be used for different rooms– , restaurants, living rooms and offices. It does not differ in complexity and their installation. The appearance of wooden elements depends on the processing of the top layer. Here are the main surface treatments:

- varnishing. Moisture coating makes the wood product more resistant to moisture and gives an attractive appearance;

- lamination. Glossy wood has excellent protective qualities;

- veneering. Veneer of valuable species of natural wood is distributed on the surface. At the same time, the panels are distinguished by excellent decorative properties.

For wood effect wall panels, there are two mounting methods. The tongue-and-groove option ensures a tight connection of all parts. In this case, you can create a single pattern. With the groove-groove method, the stitching and colors do not match. Additionally, the panels are decorated with slats and fillets. To create such products, species of pine, ash, cherry, cedar and maple are used.

There are different techniques for making wood paneling for interior walls. Let's see them in the table:

| A photo | Description |

| The most common option is a multilayer wooden panel. The top layer is made of veneer quality wood, and the middle one is from a simpler breed. The appearance completely copies the texture of the tree. |

| For the manufacture of glued boards, coniferous varieties are used. Mold does not form on the surface, as the material is resistant to moisture. |

| A glued veneer product is made of several layers that are glued to each other. To give the workpiece strength, it is necessary to glue the layers perpendicularly. This material is suitable for finishing ceiling surfaces. |

| Veneered chipboard has upper layer made of natural veneer, bottom made of chipboard. |

| The most expensive is considered a solid array. In this case, the texture corresponds to a certain breed. |

Wall decoration with wood panels has the following advantages:

- excellent aesthetic properties;

- environmental friendliness of the material;

- excellent heat-saving properties;

- durability and ease of processing;

- simple installation;

- can be painted in a different color when you get tired of facing.

Among the shortcomings, it is worth highlighting the low level of resistance to moisture and the high risk of fire under certain conditions. Panels made from real materials are expensive.

Note! All types of wood have their own special texture. At the same time, several rocks can be combined on one element, which are superimposed in layers. There is a technology that allows you to fasten the layers under pressure.

Features and characteristics of fiberboard and chipboard panels

Any patterns and textures can be applied to the MDF surface, which makes it possible to use this material for kitchens, children's rooms and office spaces. For example, 3d MDF panels are popular. They have the following benefits:

- ease of installation;

- special care is not required;

- complex preparation is not required before installation work;

- panels can be installed in different directions: across the wall, along or diagonally along the wall;

- a space is formed under the panels that can be used for laying communications, as well as electrical wires and the Internet.

Different types of panels are made from MDF. Whole-pressed ones have a smooth surface on both sides, and laminated ones are covered with a special film on the front side. At the same time, resistance to moisture and mechanical stress increases. Moisture resistant panels are made of denser materials. It uses high quality wood. This material is ideal for loggias, balconies and even bathtubs.

Since this material is perfectly applied different variants patterns, it can be used to imitate different surfaces. You can use MDF panels for brick, wood or stone.

On the front side, the surface of the material can be shaped in different variations. Painted panels are treated with a special paint that allows you to smooth out all the bumps, as well as give a matte or glossy look. Glossy surfaces are obtained by using a polymer film. The veneered surface allows you to create the texture of real wood. At the same time, a thin layer of veneer is superimposed on the MDF.

On the video you can see which MDF panels are used for interior decoration:

Features of installation of PVC wall panels for interior decoration

Now consider decorative PVC panels. They have the following properties:

- environmental friendliness. Polyvinyl chloride is used even for the manufacture of food packaging;

- fire resistance. The ignition temperature of the material is much higher than that of fiberboard or chipboard;

- moisture resistance. The surface does not accumulate moisture, which prevents the development of microorganisms and mold. Therefore, PVC wall paneling is often used in the kitchen or bathroom;

- simple installation. The material does not require preparatory work or leveling of surfaces;

- decorative. The material is distinguished by a variety of shapes and colors. With the help of the material you can decorate any surface.

Consider different types of plastic decorative panels.

| A photo | Description |

| Narrow oblong lining. At the same time, the length can reach three meters, and the width is up to 60 cm. |

| A type of tile panel. |

| For a square PVC panel, the size can vary up to a meter on each side. |

| Mosaic panels. |

There are different types of fasteners for plastic wall panels for interior decoration. They can be fixed with glue, screws, clamps and staples. For mosaic-shaped products, adhesive mounting is used. If in the room high humidity, then wooden elements should be treated with a special composition.

Seamless products can be used to finish the ceiling, since in this case the joint is practically not noticeable. There is also a chamfer connection option. Similar options are used for finishing walls and ceilings.

practical and functional interior can be used for different interiors. For, or in, plastic brick panels for interior decoration are suitable. In this case, the color palette may be different. To create more comfortable interior, filled with home comfort, it is worth finishing with wood-like plastic panels.

When choosing a PVC material, there are several parameters to consider. For example, the thickness of the plate should not be less than 10 mm. For the ceiling, products with a smaller thickness are suitable. The size of the front surface affects the ability to withstand loads.

Note! When buying products, it is important to pay attention to the appearance. There should be no damage on the surface, and the plates should be without chips and solid.

Is it worth using gypsum and gypsum vinyl panels

To create a safe interior, you need to choose environmentally friendly material. Finishing can be done with gypsum panels for interior decoration. In the manufacture of the material, modern technological processing is used. If one element is damaged, then the replacement will not have to remove the rest.

Gypsum panels are used instead. This option is popular in. With it, you can create corrugated surfaces.

It is worth noting the following advantages of the panels:

- easy installation. Gypsum can be fixed to both vertical and horizontal surfaces;

- long service life. Gypsum is resistant to mechanical stress and excess moisture;

- light weight. Lightweight material is used for panels, which is easy to mount;

- environmental friendliness. Harmful substances are not used in production;

- good soundproofing. Panels block the path of different sounds;

- low level of flammability. The composition does not contain combustible components.

With the help of modern equipment, panels are created that have different sizes, designs and shapes. An important advantage of gypsum material is the possibility of their reusable staining.

Gypsum vinyl wall panels have vinyl surfaces. At the same time, the material becomes more resistant to mechanical damage, as well as more durable and less demanding to care for. Wet cleaning is required to bring the surface in order.

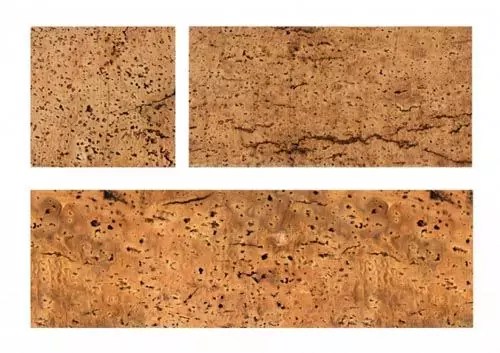

Advantages and disadvantages of cork wall panels

For clearance unusual interiors wall decoration with cork panels is used. This is a durable and lightweight material that is made from bark. Plates have the appearance of a compressed and dense mass.

Note the advantages of cork wall panels:

- safety and environmental friendliness of the material. Cork has the ability to retain harmful radiation;

- simple installation work;

- hygiene, since the material has a special structure that does not contribute to the collection of moisture, dust and dirt;

- excellent indicators of vibration isolation, sound insulation and water resistance;

- the cork does not rot and is not subject to mold;

- resistance to ultraviolet radiation.

There are certain disadvantages of wall cork panels. If dents appear on the material, they are not restored. The material does not have high thermal insulation qualities. It is important to glue cork tiles with special care, since the fixed material cannot be moved. For installation work, a special glue for cork panels is used.

decorative material used for cladding the living room, children's room, kitchen or office. He has high cost, which is quite justified, since the lining can be used for many years.

Cork coverings can be sheet or rolled. Sheet panels are classified into tiled and type-setting. At the same time, the dimensions of tiled products can vary, and for typesetting, the length can be up to six meters.

Note! Some options for cork products are made moisture resistant. To do this, they are covered with double-sided lamination based on fiberboard, MDF or PVC.

The nuances of finishing with glass panels

For rooms with increased level humidity, you can use glass paneling for walls. In some cases, they are used as .

Various patterns are often applied to the surface. In this case, they are placed between two sheets. Such a coating is not afraid wet cleaning. Such panels can also be used for other rooms, where they will perform a decorative function. The backlit glass panel looks unusual.

Wall panels with photo printing look great. They are actively used instead to divide the room into zones.

What are the features of acoustic panels

If noise from the street or from neighbors enters the room, then it is worth trying decorative acoustic panels. It's functional and beautiful. The material is often used for finishing apartments, professional studios and cinemas.

Here are the positives of acoustic wall panels:

- environmental friendliness;

- excellent sound insulation;

- variety of sizes;

- variety of styles and colors.

Acoustic elements are made of different materials. Options for hard and soft panels on the wall can be used. Most often it is plastic, wood, foam rubber, MDF and fiberglass.

To choose a suitable coating, you need to decide on the place of their use. For the bathroom or kitchen, glass options are suitable. For the living room or bedroom - made of wood. For the hall, gypsum products will be appropriate. There are also special acoustic ceiling panels. Long and thin products lengthen and visually expand the room.

Interesting information! In professional studios, plates with corrugated surfaces are used for cladding. They not only absorb extraneous noise, but also improve the quality of the recording.

The use of wall 3d panels for interior decoration

To the news quality finishes include options for 3d panels made of wood and other materials. The technology of their manufacture is not so complicated. It includes 3 stages:

- first, a sketch and computer models with the necessary relief are made;

- then the drawing is transferred to the material and undergoes special processing;

- then finishing of finished products is carried out.

What are 3D panels you can see in the video:

The finishing of the material is carried out using a PVC film, wood veneer and paint.

The use of wood panels for 3d walls refers to expensive types of finishes. For production, wood species such as oak, maple, alder or cedar are used. Before installation, they are covered with a special wax that protects the surface from moisture penetration. With the help of wall panels, you can give the room a respectable look. To prolong the service life, the surface is rubbed with special compounds.

Installation of 3D gypsum panels can be done without much difficulty. Due to the variety of patterns and aesthetics, gypsum products will help create an interior in different styles - exotic or retro. They can be mounted on any surface. The material is not afraid of moisture.

You can make it yourself, for this you need to buy molds for gypsum 3D panels. After finishing, such products do not need complex care.

Panels made of any material are easily mounted on the crate and there is no need to specially align the walls before that.

Let's highlight the advantages of the material:

- unique and unusual design;

- various forms;

- a huge selection of patterns, colors and materials;

- do not absorb foreign odors;

- The coating protects against mechanical damage.

Such products are becoming increasingly popular among a variety of finishing materials. A variety of original designs can be seen in the photo of 3D panels for walls in the interior.

Features of the use of decorative panels in rooms with special climatic conditions: photo examples of interiors

To choose the right material, you need to understand the options for its fastening. The most commonly used glue and frame technique. A good solution and self-adhesive options. To do this, you need to correctly attach the material and press it. Ordinary panels are attached with strong glue. With the adhesive method, it is impossible to hide wires and other communication details under the coating.

For rooms with a high level of humidity, PVC panels are suitable. This option successfully replaces wood, or. Plastic provides great opportunities for creating room design. Manufacturers apply a special protective coating.

Also, special panels with non-combustible properties are used for the kitchen. As an option, acrylic is used, which is subjected to additional processing. The use of acoustic options will provide a favorable microclimate in the room.

Note! The crate is made using metal profiles or wooden slats. To assemble the frame, a guide is attached to the ceiling. The profile is fixed with self-tapping screws and dowels.

How to choose bathroom panels

The bathroom is different in its specificity, in which temperature changes and high humidity can provoke the occurrence of fungus. Therefore, they are specially applied for this room. They are made from a special polymer using additional additives.

To decorate the walls of the bathroom, you can use the following waterproof wall plates:

- tiled products look like a square and are used to create a wide variety of ornaments;

- rack panels are fastened with brackets;

- sheet elements are large.

For a high quality finish, you can use sheet plates, which or . The material is covered with special protective compounds.

To visually raise the ceiling, it is recommended to install vertical wall panels for the interior decoration of the bathroom. You can fasten the material with glue, and if the products are fixed on the frame, then screws and staples are used.

Tiled elements are often made of plastic. They are used to simulate a mosaic coating.

What to consider when choosing panels for the kitchen

Instead of the usual ones, you can use . They are often installed in the zone. When installing, you do not need to level the walls or purchase additional materials. This finish allows you to disguise various communications: cables, or wiring.

When choosing decorative panels for the kitchen wall, it is important to consider that in this room there is high humidity, temperature fluctuations, as well as frequent cleaning.

It is important that the material in the apron area is moisture resistant and heat resistant. In this case, the finish should not absorb moisture.

Available for any budget best option taking into account the general interior. Great solution use wall panel for kitchen. Under the coating, you can place a layer of thermal insulation. The universal solution is plastic. At the same time, you can choose plates of different textures, shapes and color palettes.

If you plan to glue PVC panels, then you must first prepare the surface. It should be primed and left to dry completely.

Note! To remove construction adhesive after installation, wipe the surface with a damp cloth or soft sponge.

The price of wall panels for interior decoration

Decorative panels are made from a variety of materials, which allows you to choose the right option. The choice from the presented variety must be made on the basis of what properties of the finish are required. Before you buy wall panels for interior decoration, you need to consider where the material will be used.

In the table you can see the prices for some products.

| A photo | Products | Description | Price, rub |

| Panel, timber imitation. Building 61 | When choosing wooden wall panels, the price is not of primary importance. Environmentally friendly material from modern wood species. | 300 |

| HDM sheet panel | Used for an apron. | 1290 |

| Wooden wall panel. Studio DKM | Decoration with natural wood. | 15 000 |

| MDF panels Wand Der Welt | Oriental beech color. No additional fasteners are required for installation. | 250 |

| Ecofactor. Wood-polymer composite panel | The material is suitable for cladding. It imitates wood wonderfully. | 850 |

|

Different materials can be used for interior wall decoration in different rooms. Each species has its own characteristics, cost, appearance. An excellent choice for different rooms are special wall panels for interior decoration, which have a great appearance, imitate a variety of exquisite, unusual materials, as well as easy to install, which even a beginner can handle.

The use of panels in conjunction with the crate makes it possible to hide various disadvantages, defects on the walls that cannot be eliminated by standard alignment. A photo of such panels is presented below in large numbers, and they look great in different interiors. Decorative panels are produced from different materials, but plastic products are most often chosen, which are reliable, high-quality, attractive and inexpensive.

For their production, different types of materials are used. Since they are intended for use in residential premises, they are environmentally friendly, therefore they cannot cause any harm to residents of an apartment or house. In the selection process, it is important to pay attention not only to the material of creation or the design of products, but also to their colors, appearance, since decorative panels for interior wall decoration should fit perfectly into the existing interior.

Rack

They are represented by small boards that are made of PVC or other popular materials. As a rule, their length varies from 240 to 370 cm. Due to the large selection of lengths, it is possible to choose products suitable for a certain wall height. The width can also be different, since it varies from 12.5 to 30 cm. The thickness starts from 8 mm and ends at 12 mm. Rack panels made of PVC or other materials are used, usually for low walls, and are also considered ideal for small rooms.

They are mounted using a frame created in advance on the walls, and metal profiles or wooden slats can be used to create it. The elements are connected to each other with special grooves and spikes, which they are equipped with even during the production process. These fasteners are located at the end of each part.

They are fixed to the frame with self-tapping screws or special brackets, and in the second case, you must have at your disposal a special tool - a construction stapler. If there is a need to make hidden installation, then clamps are used.

Elements can be mounted both vertically and horizontally. It is allowed to use a special way - a Christmas tree. Most often, PVC or chipboard, as well as MDF, are used to create rack products.

Wooden

Wooden  metal

metal  MDF

MDF  PVC

PVC Tiled

Presented in square shape, and their sizes can be different. With the use of such panels, it is possible to lay out an original, unique picture on the wall. They are produced in a huge number of colors, textures, therefore they are an indispensable material in the process of the work of designers.

With the help of tiled products, an unsurpassed interior is formed, as well as unique design fantasies are embodied.

Such decorative panels are fastened for interior wall decoration with the help of clamps or special glue. It is allowed to combine them with other materials. Often they are used only for part of the wall. PVC elements are considered the most popular, as they are affordable and easy to use. Since all elements are the same size, clear shapes, visual surface alignment is ensured, and a neat, really attractive finish is obtained.

leafy

They are considered the most convenient elements for prompt, high-quality installation. They are ideal for large spaces. Their dimensions are significant, and the thickness can even reach 6 mm.

Sheet elements are multi-layered, and the most popular are details that imitate a variety of exquisite, unique materials. They can be made of PVC or other raw materials. Their photos can be easily found on the Internet. Installation is carried out with the help of glue, but among themselves they are fixed with the help of special moldings. It is allowed to use them even in the case of preliminary creation of the frame.

Wooden

Wall panels for interior decoration, created from wood, can have different shapes and sizes. They are available both smooth and with a unique embossed pattern. For each individual interior, the most optimal and suitable option is selected.

To create them, oak or larch, cedar or alder wood is most often used. If cheap material is used, then in the production process unique technologies, providing imitation of expensive, refined wood. For this, special compositions are used that ensure the formation of darker fibers and an unusual texture.

Wood elements are considered an excellent choice for any premises in residential real estate, and this is due to the following parameters:

- ecological purity due to the use of natural, safe components;

- if you choose a material that is impregnated with special moisture-resistant compounds at the factory, then it can be used even in rooms with a high level of humidity;

- presented wooden panels in different types, photos of which are located on the Internet, so for each room the optimal material is selected to create a coating;

- wood is considered a traditional material, the texture of which fits perfectly into a variety of interior styles, so a truly bright, unusual finish is guaranteed;

- the cost of such products may be different, since it depends on the raw materials used, however, for each person it is possible to choose an option at the best price.

The disadvantages of products formed from wood include the lack of good resistance to moisture or fire, if special protective coatings were not applied to them during the production process.

Cork

Cork panels are an excellent choice for any room. They have incredible large quantity pluses, which include:

- environmental friendliness, since only safe components are used in the process of their production, as well as cork tree bark, which is considered high-quality and unique;

- from this material, products are obtained that are distinguished by high thermal and sound insulation parameters;

- seeing such panels in the photo, each person will be convinced of their attractiveness and originality;

- material racks before exposure to moisture;

- elements easily withstand high temperatures, and also do not support the combustion process;

- cork is not able to absorb foreign odors;

- it is resistant to ultraviolet radiation or temperature changes;

- Installation is simple, so anyone can handle it.

Cork panels can be not only wall, but even floor. They are equipped during the production process with locking joints, due to which not only the installation procedure is simplified, but also a seamless and even coating is obtained. They are available in different shades, so the creation of an optimal color coating is ensured.

Acoustic

They are most often used in apartments where sound insulation is low. Due to this finish, noise coming from neighbors, from the street or from the entrance is reduced. They are created from different materials, but PVC is most often used for this. Their important parameter is porosity, due to which excellent soundproofing parameters are provided.

The most commonly used insulator is acoustic foam, which is available in a variety of different forms and sizes. It is combined with plastic or other panels, so it is not visible after finishing. In addition to foam rubber, other soundproof materials can also be used, and usually their structure differs more high rate rigidity. Installation of such products is easy, and the apartment becomes protected from extraneous sounds from the street or from neighbors.

Plastic or gypsum fiber acoustic panels are extremely common among apartment owners located in apartment buildings. Due to their use, the soundproofing parameters of all residential real estate are increased, which significantly increases the comfort of living.

3D panels

They are also formed from PVC or other popular materials. They fit perfectly into different interior styles, and also have an incredible appearance. They become a unique decoration of any room.

As a rule, such plastic 3D panels are additionally highlighted with lighting, which improves the appearance of the wall. Drawings can be varied, and are selected depending on the room in which it is planned to carry out repair work.

3D panels are created not only from PVC, but also from wood, aluminum, gypsum or MDF. There are a huge number of photos of such panels that differ in images, sizes and parameters. All species are environmentally friendly and attractive. Due to the complex structure, the heat-insulating and sound-proofing parameters of the premises increase. Fastening is usually done using a frame, so there is no need to level the wall surface, so a lot of time is not spent on preparing the base.

Basic properties

PVC panels, as well as other varieties of this material, provide an excellent transformation of different interiors. At the same time, they solve numerous problems that cannot be fixed with wallpaper or other finishing materials. These include the following characteristics:

- various irregularities or other problems are hidden on the base base of the wall;

- elements of communication networks are held behind the cover;

- insulation and soundproof materials are laid in the crate, which increases the thermal insulation parameters of the apartment, and it is also protected from extraneous sounds from the outside;

- By selecting panels that imitate refined, unique materials, a unique and expensive finish is ensured.

Photos of the finished finish from different panels are presented on the Internet, so you can choose the best option for a concert venue. Additionally, the panels are environmentally friendly and fire-resistant, resistant to moisture and easy to install.

Dimensions

Panels can be presented in different dimensions and sizes. The following types and their parameters are distinguished.

Each option has its own characteristics and parameters, which are described above. When choosing, usually not too much attention is paid to the dimensions of the panels, however, this factor is considered quite important, since it affects the ease of transportation and installation of the material, as well as the appearance of the already obtained coating.

Color and pattern

PVC panels, as well as other types of panels created from various materials, are presented in a huge number of colors and textures. This allows you to choose elements that imitate a variety of exquisite and expensive materials.

For each interior and premises, the optimal color scheme or even a separate image is selected, which will be formed from panels. When choosing a finishing material, many people initially pay attention to its appearance, since the atmosphere created in the room depends on it.

Soft and calm colors and textures are chosen for the bedroom, and marine motifs are great for the bathroom. For the kitchen, it is desirable to choose bright and cheerful colors. However, in addition, when choosing a color and texture, each person who owns the premises should be guided by their preferences.

Thus, wall panels designed for interior decoration are considered an excellent choice for every room. They are presented in a huge number of types, have many advantages and are easy to install. Therefore, the process of their installation is easily implemented on their own.

Video

Interior finishes with different kind panels.

Photo with options for how wall panels in interior decoration might look

Examples of interior wall decoration with panels of various materials.

It is rather difficult to keep track of the rapid growth of the range of finishing materials in our country. The choice of such goods is very large. But samples from different materials are especially popular among buyers. Today we will introduce you to the most popular products of this group.

Wall panels (for interior decoration) today are made not only from traditional wood, which corresponds to the classic style of the interior, but they are made from new and modern materials.

Wall panels for interior decoration

The panels are produced on the basis of plastic (siding, plastic mirror, PVC), drywall, mineral wool. As a result, they differ technical specifications and, accordingly, the scope of their application in construction.

According to trade workers, MDF and PVC panels are the most popular. Why is this type of finishing material so in demand today? Wall panels for interior decoration have significant advantages over other materials. First, they are easy to install. Anyone can do this job. Secondly, in a matter of hours, with the help of panels, you can completely transform the room.

natural wood panels

A strict and elegant look is the main reason for their growing popularity. Such panels have long moved from offices to living quarters. They decorate living rooms, lobbies, corridors.

Wooden panels can also be mounted on the ceiling. Moreover, such decor is used not only in the classical style. It will be quite appropriate in the English style, art deco or modern.

Naturally, the price of panels made of precious wood is quite high.

MDF panels

MDF boards are a modern modification of fiberboard. Thanks to modern technology production managed to achieve a much higher density of the material.

Internal is possible in rooms with a high level of humidity, since they are moisture resistant. Such samples are easy to grind, and when cut they do not crumble or break.

Panels made of fiberboard and chipboard

In the manufacture of these materials, various synthetic resins are used. Recently, they do not contain formaldehyde - a substance hazardous to human health.

Some types of chipboard panels are made from wood chips that are compacted with lignin, a natural wood glue. This is an environmentally friendly material.

Often chipboard panels are trimmed vinyl wallpaper, textiles, which are glued with a special glue. Such samples improve sound and heat insulation in the room, reduce acoustics.

On the Russian market, MDF, fiberboard and VSP panels are represented by Agnes, One Step, Atex, Kosche, BS, Kronospan, Klassen, HDM, OSMO.

PVC panels

This type of panels is made of hard plastic with the addition of a special softener.

PVC-based interior trim has a number of undeniable merits. They do not contain cadmium and asbestos, they are easy to clean, they are moisture resistant even at the joints, do not ignite and are durable. At the same time, air is passed through, which allows the coating to “breathe”.

Today, many of our compatriots use PVC panels for walls. For interior decoration, they are also convenient to use because they increase the level of sound insulation.

Diverse design

A huge advantage of this material is a wide variety of colors, patterns, patterns, which allows you to choose finishing material for any interior.

The pattern on the PVC panel is applied by printing method, and then it is varnished, thereby increasing the antistatic, resistance to ultraviolet rays and mechanical damage. The coating can be matte or glossy, and its strength is three times higher than that of lacquered wood.

PVC panels can be installed in the bathroom, toilet, kitchen, as they are absolutely not afraid of water.

Russian buyers are well aware of the products of such companies as Harol, Deceuninck, Grisfillex, Plastivan.

Mirrored

Such spectacular panels are widely used in hallways, bathrooms, bedrooms. Quite often they are used in small apartments for visual magnification space.

Mirror panels for walls (for interior decoration) are made of polystyrene. From above they are covered with a plastic film, which can be mirrored or tinted. Panels are available in classic version or self-adhesive.

They cut well, it is quite easy to apply embossing and text on them. Due to the flexibility of the material, they are used for finishing columns, pylons, arches and other elements that have a rounded surface. Such panels are supplied to our market by the Austrian company SURO-BURG.

Cork panels

This material is not yet very common in our country, although it deserves attention. Cork is a plant tissue obtained from the bark of the cork oak that grows in Portugal. One cubic centimeter of such tissue contains about 40 million air-filled bubbles. This is a unique material - hypoallergenic, environmentally friendly, with strong soundproofing properties.

Plasterboard panels

We have been accustomed to drywall in our homes for a long time. It is used in different types - plates of different sizes and panels, which are covered with vinyl with a decorative finish.

Depending on the material that covers the gypsum board, the panels are made of the following types:

- using the material "Pletex";

- with PVC coating based on Devilon paper;

- with PVC coating based on "Isoplen";

- with PDO or PDSO film in the interior.

Brick interior wall cladding

Today, the use of brickwork elements in the interior is widespread. It can be whole walls lined with decorative blocks, or small fragments made of both brick and materials that imitate it. It can be painting, wallpaper and various panels.

Decorative ones made of plastic are distinguished by the fact that on one product that imitates masonry, there are "bars" different shades. For the manufacture of such products, in addition to MDF and PVC, other materials are used (hardboard, plywood), but they have limitations in installation.

Advantages of wall panels

1. A fairly simple installation allows you to perform all operations yourself, in the shortest possible time. The area of one sheet varies from 3 to 8 m 2. Panels being cut with a regular hacksaw for metal.

2. The light weight of the panels makes it possible to veneer almost any surface, regardless of the basis of the material. At the same time, there is no need for costly preparatory work, which naturally reduces the total cost of repairs or construction.

3. Wall panels are a truly versatile material. They can be used both inside and outside the building, for decorating ceilings, walls on a loggia or balcony.

5. The panels have a long service life - at least 10 years.

6. Choosing the right type of wall panels and following the rules for their installation, you can significantly increase the moisture protection, heat and sound insulation of the room.

Decorative interior wall panels— this is the best option for those cases when you need to quickly transform the room with minimal costs for finishing material and its installation.

A large selection of such finishing material, produced from natural and artificial raw materials, allows you to choose exactly the option that is well suited for the price and appearance for a particular interior. The panels are easily installed on the surface of walls and ceilings and do not require lengthy preparation before installation. It is these advantages, as well as the aesthetic appearance of the panels, that have made them popular enough for widespread use.

Decorative panels are in perfect harmony with other finishing materials, so they can be safely combined with wallpaper that is close or contrasting with them in tone, as well as with painted walls.

Criteria for choosing decorative wall panels

Panels for interior decoration must meet certain requirements, so when buying these features, you must definitely pay attention to:

- For the manufacture of finishing material should be used environmentally friendly raw material, which during operation will not be subject to the process of decomposition and the release of substances hazardous to human health.

- Panels must be made of non-combustible and non-flammable material. In addition, in the event of a fire, it should not create smoke in the premises. To determine how safe the finishing material is, when purchasing it, you should pay attention to the markings on the packaging. If there is no fire safety class marking, and the product is not accompanied by a certificate of conformity, then it is better to refuse to purchase immediately.

| Criteria for evaluation fire hazard | Classification of fire hazard of materials in ascending order. When marking NG (non-combustible), there are no other fire hazard properties | |||

|---|---|---|---|---|

| combustibility | G1- slightly flammable | G2- moderately combustible | G3- combustible | G4- highly combustible |

| Flammability | IN 1- flame-retardant | IN 2- moderately combustible | IN 3- highly flammable | |

| Smoke formation during combustion or smoldering | D1- little smoke | D 2- moderate smoke | D3- high smoke | |

| Toxicity of combustion products. | T1 - low risk | T2- moderately dangerous | T3- highly dangerous | T4- extremely dangerous |

| fire spread | RP1- not spreading | RP2- weak spreading | RP3- moderately spreading | WP4- highly spreading |

- Finishing material should be selected for resistance to moisture. depending on the premises for which it is purchased.

- The general requirement for all panels is strength and elasticity. When choosing, you must also consider what effect will be exerted on the material. For example, if the panels are purchased for a children's room or a room where pets will be, then a material that is easy to care for and durable to mechanical scratching load is chosen.

- The panels should easily endure temperature changes, as some of them can be installed near the battery and the window.

- Ease of cleaning and resistance to detergents is also an important factor when choosing a finishing material, especially if it will be installed in the kitchen, in the hallway or in one of the corridors.

- Highly important criterion of choice is the ease of mounting the panels.

Panel functionality

Using decorative panels for wall decoration, you can not only transform the interior of the room, but also get rid of problems that cannot be solved by simply sticking wallpaper:

- Behind this finish, you can hide bumps and other flaws in the wall.

- Communications can be carried out behind the panels highways - cables or pipes.

- When installing panels on a frame crate, it becomes possible to lay heat and sound insulating material behind them. In addition, there are panels on sale already equipped with a layer of such insulation.

- Panels made from artificial materials often imitate natural ones very reliably.

Video: examples of using wall panels for decorative interior decoration

Varieties of panels in shape and material

These decorative finishes can be divided into different types according to the form in which they are produced and according to the materials of manufacture.

Release form

Today on sale you can find panels the following forms release:

- Tile. It is produced in the form of rectangles and squares. different sizes, various colors and textures. The tile is well combined with each other and with other materials, can be used to decorate the entire wall or its panel part.

Due to the clarity of the forms, this type of finish gives the room neatness, leveling the surface. Such panels are mounted on a crate made of wooden bars and installed on the wall. The size of tile panels can vary in length from 300 to 980 mm, width from 250 to 500 mm, which allows you to create mosaic surfaces from them, choosing different textured patterns.

- Reiki. This type of panels has a rectangular shape and is in fact the same lining, made not only from wood, but also from other materials, natural and artificial. The length of the slatted panels varies from 2400 to 3700 mm, and the width from 150 to 300 mm. Their minimum thickness is 8 mm, and the maximum reaches 12 ÷ 15 mm. For concealed installation of such rails on the crate, special fasteners are used - clamps. These panels can be mounted both horizontally and vertically. so-called "herringbone» .

One of the most common options is clapboard-shaped panels.

This type of panel is most often used to decorate rooms with a small area, as they do not visually reduce the space of the room. Between themselves, the rack panels are connected using a tongue-and-groove lock or only grooves, inside of which special narrow tabs are inserted.

- Sheet panels are produced with a thickness of 3 to 10 mm and have large dimensions - from 1200 to 2450 mm. Surface sheet material imitates various natural textures, such as stone, various types of wood, cork and other materials, so you can easily choose the right sheets for an interior decorated in any style. This type of panel is most often mounted only on flat surfaces with glue, but sometimes they are attached in the same way as other types of finishing materials to the crate.

The joints between the installed panels are masked with special moldings that give the surface neatness. These panels are most often made from sheet fiberboard or MDF, which is decorated with various natural materials.

Production material

The wall panels themselves can be made of various materials, and in addition, the surface of many of them is additionally covered with a special decorative layer. So, in hardware stores you can find the finish:

- From natural wood of different breeds with a variety of textured patterns.

- Made of polyvinyl chloride (PVC). These panels can be plain, or any pattern, textured or tinted, can be applied to them.

- Acoustic foam rubber VS and fibers of synthetic origin, bonded with gypsum and polymers, are used to make soundproof boards. This type of panels is decorated on top gypsum fiber material or plastic.

- Gypsum vinyl boards, which consist of gypsum closed on both sides with vinyl plates, like drywall.

Relatively new finishing material - gypsum vinyl panels

- Cork panels, which are not only an environmentally friendly finishing material, but also absorb sound well.

- Panels based on fiberboard, MDF or chipboard.

- 3D panels made from different materials or their combinations.

Characteristics of various wall panels

To know for which premises this or that is suitable type of material from which panels are made, you need to consider their characteristics, as well as how they will look in the interior.

wood panels

Wood panels are produced in various options- these can be smooth square or rectangular elements with a relief pattern or assembled from several parts and having a finished appearance.

Most often, panels are made from cedar, oak, larch, alder or maple wood. If for their production it is used completely inexpensive material, then they try to disguise it as more valuable wood with the help of special compounds that will make the texture pattern clearer and darker than the fiber.

Wood panels are ideal for interior design, as they are an environmentally friendly "breathing" material. You can also use them to decorate rooms with high humidity, but in this case it is necessary to choose a material impregnated with water-repellent compounds and coated with wax on top.

Recently, panels from split solid wood, arranged in different variations, are gaining popularity, as a result of which relief patterns are obtained with a visible structure of the fibers of the material and each knot in it. This technique of making panels helps to preserve the natural beauty of the wood, as it does not show traces of processing. For the manufacture of such plates, ash, birch and oak are used - all of them have chipped beautiful drawing. Finished plates are covered with colorless varnish or wax.

Chipboard and MDF panels

Chipboard (chipboard) is composite material made on the basis sawdust and shavings. To bind these woodworking wastes, phenol-formaldehyde resin is used, which can be from 5 to 17% of the total mass. The prepared mixture goes through the stage of flat hot pressing, after which it turns into plates. After that, the panels are most often covered with wood veneer and laminated.

MDF - can be deciphered as a finely dispersed fraction, that is, plates, are made from from shredded lumber. The panels are formed using dry pressing, and urea resins, which are less toxic than formaldehyde, serve as a binder for raw materials. MDF are classified E1, that is, they have the least degree of danger to human health, which opens them up to the widest use in residential premises. The remaining characteristics are similar to those of chipboard.

Chipboard and MDF can be "disguised" as any type of wood, and quality material is sometimes quite difficult to distinguish from natural wood.

According to some characteristics, chipboard and MDF are even superior to wood - the boards are strong and fairly rigid, but if necessary, they can be easily processed. Chipboards have a lower flammability classification than natural wood have sound and heat insulating properties.

To disadvantages conventional slabs Chipboard and MDF can be attributed to low moisture resistance, since when wet they swell, and their thickness increases by 5–30%, which leads to deformation. Therefore, this material cannot be used for finishing wet rooms. However, in addition to conventional chipboard boards for rooms with normal humidity, moisture-resistant wall panels are also produced, but they have a higher price.

You also need to know that the phenol-formaldehyde resins that make up the panels are extremely harmful to human health, and they will be released from the panels throughout the entire period of their operation. Therefore, it is undesirable to use chipboard for finishing any residential premises. Such material may be suitable for putting in order the walls of halls, walk-through corridors and other well-ventilated rooms. In any case, before deciding to purchase chipboard panels, you should familiarize yourself with their performance characteristics indicated on the label or in the technical documentation for the consignment.

The main characteristics of chipboard:

| Material parameters | Peculiarities | Residential use | |

|---|---|---|---|

| Chipboard classes domestic production for security (phenol-formaldehyde content per 100 g of dry raw material) | E0 | Is absent | used |

| E1 | Not more than 10 mg | used | |

| E2 | Not more than 30 mg | Not used | |

| E3 | Not more than 60 mg | Not used | |

| Chipboard brand | P-A | Moisture resistant, durable and less prone to deformation. | Rooms with high humidity. |

| P-B | Has lower scores | ||

| Density, kg/m³ | very small | 350-450 | |

| small | 450-650 | ||

| average | 650-750 | ||

| high | 750-800 | ||

| Material grade according to GOST 10632-89 | 1 grade | Laminated. They do not have external flaws, in the form of chips, scratches, uneven edges and surfaces. | used |

| 2 grade | Has an outer coating. Defects in the form of small chipped edges, scratches and other damage are allowed on the material. | ||

| 3 grade | With and without coating. It is considered defective material, it is used as an auxiliary material, for example, for the manufacture of formwork. | Depending on the amount of formaldehyde content | |

| Standard sizes of plates, mm | Length | 5680, 5500, 5200, 4100, 3750, 3690, 3660, 3600,3500, 3220, 2840, 2800, 2750, 2700, 2600, 2500, 2440, 2040, 1830 | |

| Width | 2500, 2440, 2135, 2070, 1830,1800, 1750, 1500, 1250, 1220±0.5mm | ||

| Thickness | 28, 22, 19, 18, 16, 10, 9, 8±0.3mm | ||

Here it should be noted that chipboard produced abroad have different standards, and especially they are different in terms of formaldehyde content. For example, according to European standards, the maximum allowable percentage of this substance for the class E1- 8 mg, E2- 8÷15 mg, E3 - 35÷40 mg, that is, its concentration is reduced by an average of 20%.

It is worth mentioning the number of layers that chipboard can have. The material is produced in one-, three- and five-layer versions, as well as in the form of slabs with a special design called “tambourat”. Most often, three-layer slabs are used for panels, which consist of an inner layer of large chips, a middle layer of fine sawdust, and a top layer - this is one of the coatings used.

"Tamburat" consists of outer layersmade of chipboard or MDF, between which cellular cardboard is placed - this is a lightweight material that has a structure similar to a sandwich panel.

Fiberboard panels

Fiberboard - wood fiber plate. As the name implies, it is made from wood fibers that are crushed and then pressed together under high pressure. Previously, the same phenol-formaldehyde resins served as a binder for raw materials in the manufacture of boards. Today, well-known manufacturers of finishing materials are abandoning these substances and switching to a completely environmentally friendly net production by applying the resin of the eucalyptus tree. The price of such products is much higher, but they are not harmful to human health, since they do not emit toxic fumes into the air.

Improved decorative panels made of chipboard can be used for finishing any premises, including those with high humidity. The composition of the finishing waterproof version of the material, in addition to resins, includes water repellents, and the outer surface of the panels is covered with a polymer film, that is, it is laminated. Such processing does finishing plates resistant to mechanical, thermal stress and moisture, significantly extends their service life.

This is not brickwork, but a very successful imitation of fiberboard panels

The surfaces of the panels are decorated with a variety of materials - they can imitate natural stone, wood, brickwork or ceramic tiles. High-quality execution brings the appearance of the plates closer to the imitated materials so much that it is sometimes difficult to distinguish them from the original. At the same time, the plates have a lower price than natural finish and their installation is much easier and faster, which allows you to create the desired design at a lower cost.

Fiberboard sheets may have maximum length 3600 mm, width 1800 mm, and their thickness ranges from 3 to 25 mm. Such sheet dimensions allow you to close a large area at once, which makes installation both faster and better. Panels can have different structural densities and are divided according to this criterion into three types:

Installation of fiberboard panels

Before installing decorative panels on the walls, they are brought into the room where they will be installed and left for several days to adapt to the temperature and humidity conditions.

The connection of plates or sheets of fiberboard during their installation in one plane can be done in two ways:

- The most famous and simple is with the help of a thorn-groove lock.

- The second method is a groove-groove lock, into which a fastening tab is inserted.

As a rule, the panels are fixed to a crate of wooden slats or timber, pre-installed on the wall. The elements of the crate are fixed vertically or horizontally, parallel to each other at a distance of 400 ÷ 500 mm, taking into account the dimensions of the selected finishing slabs. The panels are fixed perpendicular to the elements of the crate with the help of special metal elements - clamps, so their fastenings from the outside are absolutely not noticeable.

If the wall for the installation of plates is leveled and requires only decorative finishing, then the material can be glued to it using liquid nails glue.

Gypsum vinyl panels

Gypsum vinyl decorative boards are identical in structure to drywall, but instead of a double-sided cardboard surface, vinyl plates are used for their manufacture, which gives the material higher strength and an aesthetic appearance that does not require additional decorative design. The material has affordable price and therefore it is quite in demand for finishing walls and partitions of residential and non-residential premises.

Panels made of these materials are durable and resistant to mechanical stress, as well as to detergents. Finishing is easily put in order with the help of wet cleaning, as it is resistant to moisture and aggressive environments. Therefore, the material is used not only for mounting it on walls, but for decorating slopes of window and door openings.

Slabs are produced in sizes 2500 × 1200 and 300 × 1200 mm, 12 mm thick, and have more than 150 different colors that can be combined with each other and combined with other finishing materials.

Color palette for every taste

Most often, gypsum vinyl boards are mounted using aluminum profiles having different color schemes, so they can be easily matched to any panels. If the plates are purchased from a specific manufacturer, then the material and fittings can be selected from the existing catalog.

A very important point in the installation of this material is that it is carried out without a large amount of debris and dust. It is this quality that allows you to carry out finishing in an already finished interior.

A few words about fire safety gypsum vinyl finishing material. Its combustibility is classified as G2 (moderate), smoke generation- D1 (very low), flammability - B2 (moderate), smoke toxicity during combustion - T1 (low toxicity).

For the installation of gypsum vinyl, different profiles are used. For example, for mounting on walls, a 60 × 27 or 27 × 28 mm PP profile is used. To install partitions, PS and PN profiles are used, and the average width of such a partition is 85 ÷ 95 mm. Between the plates in this design, you can lay soundproof material or lay communications. A finished partition may well replace a full-fledged wall.

PVC panels

PVC panels are quite popular for tidying up the walls of residential and non-residential premises of an apartment or a private house. They are produced in the form of lining or in sheets, the width of which can be 100, 250, 375, 500 and 1220 mm, and the length is 1035, 2240, 2700, 3000 and 6000 mm. The thickness usually varies from 3 to 8 mm.

PVC panels are inexpensive, easy to install and easy to maintain

By purchasing panels in sheets, you can greatly facilitate and speed up the installation process, since a large plate immediately covers a large area of \u200b\u200bthe wall.

PVC panels are produced without the use of substances hazardous to human health, therefore, during operation, they do not emit toxic fumes into the air. The material is moisture resistant, easy to clean and is not afraid of household detergents. For wall decoration in rooms with high humidity, special moisture-resistant panels are produced that do not require special care– Wipe them periodically with a damp and dry cloth.

PVC panels are perfect option for rooms with a high level of humidity

PVC panels are produced in different colors, they can imitate any natural material (stone, wood, etc.), and besides, they can be patterned with brickwork, tiles, mosaics, etc.

Panels installed on the wall will perfectly mask the pipes in the toilet and bathroom, behind them you can skip various cable communications, and, if necessary, lay soundproofing or insulation material.

PVC panels are mounted not only on the walls, but also on the ceiling, and are perfectly combined with the lamps embedded in them.

Mounting this material on a wall or ceiling occurs in two ways:

- Fixing them to wooden crate, using clamps or self-tapping screws.

- Adhering to a flat surface liquid nails» or glue on a gypsum-cement basis.

To put in order the external and internal corners of the finish, special fittings are produced. It should be noted that a high-quality installation of this material on the walls can be carried out by anyone, even a novice builder, who will follow the technology, carefully mark up and control the horizontal and vertical installation of each element.

Qualitatively mounted PVC panels, subject to the recommended rules of operation and maintenance, are guaranteed to last up to 50 years, at normal room temperature, without sudden changes in one direction or the other.

Cork panels

Cork panels are perfect for decorating any of the rooms of a residential building or apartment. This material has many advantages over any other.

- The first and most important is the absolute ecological purity of the material.

- Cork is valued for its excellent heat and sound insulation qualities.

- The material is distinguished by high moisture resistance.

- Cork does not absorb external odors, even such strong ones as tobacco smoke and kitchen aromas.

- The panels withstand high temperatures, reaching up to 350 degrees, but even when this threshold is reached, the material smolders, but does not support combustion. At the same time, the cork does not emit a large amount of smoke and toxic substances.

- The resistance of the material to ultraviolet radiation, temperature extremes and to all types of microflora allows the material to be used long time, since it does not change its original appearance.

- Ease of installation of finishing material - it is quite possible to do without additional insulation and installation of battens, if the wall has a flat surface. Works on finishing walls with cork are not accompanied by the formation of dust and a large amount of debris.

Panels from this unique material are produced in different sizes, and tiles are usually 300x600 or 300x300mm.

In addition to wall panels, floor panels are also made from the same material. They have special locking joints, thanks to which they form an almost seamless coating after laying.

Wall panels have a thickness of 3 mm and are produced in various shades - from amber to dark brown. These colors can be easily adapted to the interior, made in any of the existing styles. If desired, you can find a cork finishing material that has colored blotches - green, red or blue.

Installation of cork panels

Installation of cork panels is carried out in the following order:

- Surface preparation. It will need to be well leveled - you can use drywall for this, and then treat the surface with finishing putty. After drying, the coating is passed over it with sandpaper, which will create the desired level of roughness, which contributes to better adhesion of the adhesive composition.

- Marking is carried out on the prepared wall. It is best to draw the entire wall into rows, the width of which will depend on the size of the finishing panels, given that they will be fastened end-to-end.