Details of expansion joints in brick buildings. Expansion joints in buildings

Any building structures, regardless of what material they are made of (brick, monolithic reinforced concrete or building panels), change their geometric dimensions when the temperature changes. When the temperature drops, they shrink, and when they rise, naturally, they expand. This can lead to cracking and significantly reduce the strength and durability of both individual elements(for example, cement-sand screeds, blind area of foundations, and so on), and the entire building as a whole. To prevent these negative phenomena, the temperature seam serves, which must be equipped in the appropriate places (according to regulatory building documents).

Vertical temperature-shrinkage joints of buildings

In buildings of great length, as well as buildings with a different number of floors, in separate sections of the SNiP-th, the mandatory arrangement of vertical expansion gaps is provided:

- Temperature - to prevent the formation of cracks due to changes in the geometric dimensions of the structural elements of the building due to temperature changes (average daily and average annual) and shrinkage of concrete. Such seams are brought to the level of the foundation.

- Sedimentary joints that prevent the formation of cracks that may form due to uneven settlement of the foundation caused by unequal loads on its individual parts. These seams completely divide the structure into separate sections, including the foundation.

The designs of both types of seams are the same. To arrange the gap, two paired transverse walls are erected, which fill heat-insulating material, and then waterproofed (to prevent precipitation from entering). The width of the seam must strictly comply with the design of the building (but be at least 20 mm).

The step of shrinkage joints for frameless large-panel buildings is standardized by SNiP-th and depends on the materials used in the manufacture of panels (concrete compressive strength class, mortar brand and diameter of longitudinal load-bearing reinforcement), the distance between the transverse walls and the annual difference average daily temperatures for a specific region. For example, for Petrozavodsk (annual temperature difference is 60°C), temperature gaps must be located at a distance of 75÷125 m.

IN monolithic structures and buildings built by the prefabricated-monolithic method, the pitch of the transverse temperature-shrinkage joints (according to SNiP) varies from 40 to 80 m (depending on design features building). The arrangement of such seams not only increases the reliability of the building structure, but also allows you to gradually cast individual sections of the building.

On a note! In individual construction, the arrangement of such gaps is used extremely rarely, since the length of the wall of a private house usually does not exceed 40 m.

IN brick houses seams are equipped similarly to panel or monolithic buildings.

In reinforced concrete structures of buildings, the dimensions of the floors, as well as the dimensions of other elements, may vary depending on temperature differences. Therefore, when installing them, it is necessary to arrange expansion joints.

Materials for their manufacture, dimensions, places and laying technology are indicated in advance in project documentation for the construction of the building.

Sometimes such seams are structurally made sliding. To ensure sliding in those places where the floor slab rests on load-bearing structures, two layers of galvanized roofing iron are laid under it.

Expansion joints in concrete floors and cement-sand screeds

When pouring cement-sand screed or the arrangement of a concrete floor, it is necessary to isolate all building structures (walls, columns, doorways, and so on) from contact with the poured mortar throughout the entire thickness. This gap performs three functions simultaneously:

- At the stage of pouring and setting the solution works as a shrinkable seam. Heavy wet mortar compresses it, with gradual drying concrete mix the dimensions of the cast web are reduced, and the gap-filling material expands and compensates for the shrinkage of the mixture.

- It prevents the transfer of loads from building structures to concrete pavement and vice versa. The screed does not press on the walls. The structural strength of the building does not change. The structures themselves do not transfer loads to the screed, and it does not crack during operation.

- With temperature differences (and they necessarily occur even in heated rooms), this seam compensates for changes in the volume of the concrete mass, which prevents its cracking and increases its service life.

To arrange such gaps, a special damper tape is usually used, the width of which is slightly larger than the height of the screed. After the solution has hardened, its excess is cut off. construction knife. When set up in concrete floors shrinkage joints (in case the finishing floor covering is not provided), the polypropylene tape is partially removed and the groove is waterproofed using special sealants.

In rooms of a large area (or when the length of one of the walls exceeds 6 m), according to SNiP, it is necessary to cut longitudinal and transverse temperature-shrinkage joints with a depth of ⅓ of the thickness of the fill. The temperature joint in concrete is produced using special equipment (gasoline or electric joint cutter with diamond discs). The step of such seams should not be more than 6 m.

Attention! When pouring with a solution of underfloor heating elements, shrink joints are arranged to the full depth of the screed.

Expansion joints in foundation blind areas and concrete paths

The blind areas of the foundations, designed to protect the base of the house from the harmful effects of precipitation, are also subject to destruction due to significant temperature changes during the year. To avoid this, equip the seams that compensate for the expansion and contraction of concrete. Such gaps are made at the stage of construction of the blind area formwork. In the formwork along the entire perimeter, transverse boards (20 mm thick) are fixed in increments of 1.5 ÷ 2.5 m. When the mortar sets a little, the boards are removed, and after the final drying of the blind area, the grooves are filled with damping material and waterproofed.

All of the above applies to the arrangement concrete paths on the street or parking spaces near your own home. However, the step of deformation gaps can be increased up to 3÷5 m.

Materials for arranging seams

The same requirements apply to materials intended for arranging seams (regardless of type and size). They should be resilient, elastic, easily compressible and quickly recover their shape after compression.

It is designed to prevent cracking of the screed during its drying and to compensate for loads from building structures (walls, columns, and so on). A wide choice of sizes (thickness: 3÷35 mm; width: 27÷250 mm) of this material allows you to equip almost any screed and concrete floors.

A popular and easy-to-use material for filling deformation gaps is polyethylene foam cord. On the construction market it has two varieties:

- continuous sealing cord Ø=6÷80 mm,

- in the form of a tube Ø=30÷120 mm.

The diameter of the cord should exceed the width of the seam by ¼÷½. The cord is installed in the groove in a compressed state and fill ⅔÷¾ of the free volume. For example, for sealing grooves 4 mm wide cut in a screed, a cord Ø = 6 mm is suitable.

Sealants and mastics

To seal the seams, various sealants are used:

- polyurethane;

- acrylic;

- silicone.

They are both one-component (ready-to-use) and two-component (they are prepared by mixing two constituent parts immediately before use). If the seam is small, then it is enough to fill it with sealant; if the gap width is significant, then this material is applied over the laid polyethylene foam cord (or other damping material).

A variety of mastics (bituminous, bitumen-polymer, raw rubber-based compositions or epoxy with additives to impart elasticity) are used mainly for sealing external expansion gaps. They are applied over the damping material laid in the groove.

Special profiles

In modern construction, expansion joints in concrete are successfully closed using special expansion profiles. These products are available in a wide variety of configurations (depending on application and joint width). For their manufacture, metal, plastic, rubber are used, or several materials are combined in one device. Some models of this category must be installed already in the process of pouring the solution. Others can be installed in the groove after the final hardening of the base. Manufacturers (both foreign and domestic) have developed a wide range of the lineup fixtures for both outdoor and indoor use. High price profiles is compensated by the fact that this method of sealing the gaps does not require their subsequent waterproofing.

In custody

Proper arrangement of temperature, expansion, expansion and settlement joints significantly increases the strength and durability of any building; parking spaces or garden paths with concrete cover. When using high quality materials for their manufacture, they will last without repair for many years.

The outer walls, and together with the rest of the building structures, if necessary and depending on the specifics of the building solution, natural-climatic and engineering-geological conditions of construction, are dissected expansion joints various types:

- temperature,

- sedimentary,

- seismic.

An expansion joint is used to reduce loads on various structural elements in places of possible deformations that occur during seismic events, temperature fluctuations, uneven ground settlement, as well as other influences that can cause their own loads that reduce bearing capacity designs.

This is a cut in the structure of the building, which divides the structure into separate blocks, which gives the structure a certain degree of elasticity. For sealing, it is filled with elastic insulating material.

expansion joints applied depending on the purpose. These are temperature, anti-seismic, sedimentary and shrinkage. Temperature joints divide the building into compartments, from ground level to the roof inclusive. This does not affect the foundation, which is located below ground level, where it experiences temperature fluctuations to a lesser extent, and therefore does not undergo significant deformations.

Some parts of the building may have different number of storeys. Then the foundation soils, which are located under various parts buildings, perceive various loads. This can lead to cracks in the walls of the building, as well as in other structures.

Also, differences in the composition and structure of the foundation within the building area of the building can affect the uneven settlement of soils of the base of the structure. This can cause the appearance of sedimentary cracks even in a building of the same number of storeys, with a considerable length.

Sedimentary seams are made to avoid dangerous deformations. They differ in that when cutting the building along the entire height, the foundation is also included. Sometimes, if necessary, sutures are used. different types. Can be combined into temperature-sedimentary seams.

Anti-seismic joints are used in buildings constructed in an earthquake-prone area. Their peculiarity is that they divide the building into compartments, which are structurally independent stable volumes.

In the walls that are built from monolithic concrete various types, shrink seams are made. When concrete hardens, monolithic walls decrease in volume. The seams themselves prevent the occurrence of cracks, which reduce the bearing capacity of the walls.

Expansion joint- designed to reduce loads on structural elements in places of possible deformations arising from fluctuations in air temperature, seismic events, uneven ground settlement and other influences that can cause dangerous own loads that reduce the bearing capacity of structures. It is a kind of section in the building structure, dividing the structure into separate blocks and, thereby, giving the structure a certain degree of elasticity. For the purpose of sealing, it is filled with an elastic insulating material.

Depending on the purpose, the following expansion joints are used: temperature, sedimentary, anti-seismic and shrinkage.

Temperature joints they divide the building into compartments from ground level to the roof inclusive, without affecting the foundation, which, being below ground level, experiences temperature fluctuations to a lesser extent and, therefore, does not undergo significant deformations. The distance between the expansion joints is taken depending on the material of the walls and the estimated winter temperature of the construction area.

Separate parts of the building can be of different heights. In this case, the base soils located directly under the various parts of the building will perceive different loads. Uneven deformation of the soil can lead to cracks in the walls and other building structures. Another reason for uneven subsidence of the foundation soils of a structure can be differences in the composition and structure of the foundation within the building area of the building. Then, in buildings of considerable length, even with the same number of storeys, sedimentary cracks may appear. Sedimentary seams are arranged in buildings to avoid the appearance of dangerous deformations. These seams, unlike temperature seams, cut buildings along their entire height, including foundations.

If it is necessary to use expansion joints of different types in one building, they are combined, if possible, in the form of so-called temperature-settlement joints.

Anti-seismic seams used in buildings under construction in areas prone to earthquakes. They cut the building into compartments, which in a constructive sense should be independent stable volumes. Along the lines of anti-seismic seams, double walls or double rows of load-bearing posts are included in the system of the load-bearing frame of the corresponding compartment.

Shrink seams are made in walls erected from various types of monolithic concrete. Monolithic walls during hardening of concrete are reduced in volume. Shrinkage joints prevent the occurrence of cracks that reduce the bearing capacity of the walls. During the curing process monolithic walls the width of the shrinkage seams increases; at the end of the shrinkage of the walls, the seams are tightly sealed.

Various materials are used to organize and waterproof expansion joints:

- sealants

- putties

- waterstops

Expansion joint- a vertical gap filled with elastic material, dismembering the walls of the building. Its purpose is to prevent the appearance of cracks from temperature differences and uneven settlement of the building.

|

|

|

Expansion joints in buildings and their outer walls: |

|

Thermal shrinkage seams arrange in order to avoid the formation of cracks and distortions in the walls caused by the concentration of efforts from exposure to variable air temperatures and shrinkage of materials (masonry, concrete). Such seams cut only the ground part of the building.

In order to avoid the appearance of cracks caused by shrinkage deformations in walls made of cast concrete and from concrete stones, as well as from unseasoned silicate brick(at the age of up to three months) it is recommended to lay structural reinforcement with a total cross section of 2-4 cm2 for each floor along the perimeter of the building at the level of window sills and lintels.

The seams in the walls associated with metal or reinforced concrete structures must match the seams in the structures.

Maximum allowable distances (in m) between expansion joints in the walls of heated buildings

| Estimated winter outside temperature (in degrees) | Masonry of baked bricks, ceramics and large blocks of all types on brand mortars | Laying of silicate bricks and ordinary concrete stones on brand mortars | Masonry from natural stones on brand solutions | ||||||

| 100-50 | 25-10 | 4 | 100-50 | 25-10 | 4 | 100-50 | 25-10 | 4 | |

| below - 30 | 50 | 75 | 100 | 25 | 35 | 50 | 32 | 44 | 62 |

| from 21 to - 30 | 60 | 90 | 120 | 30 | 45 | 60 | 38 | 56 | 75 |

| from 11 to - 20 | 80 | 120 | 150 | 40 | 60 | 80 | 50 | 75 | 100 |

| from 10 and above | 100 | 150 | 200 | 50 | 75 | 100 | 62 | 94 | 125 |

The distances indicated in the table are subject to reduction: for the walls of closed unheated buildings - by 30%, for open stone structures - by 50%

With a change in temperature, reinforced concrete structures are deformed: they shorten or lengthen, and shorten due to concrete shrinkage. With uneven subsidence of the base in the vertical direction, parts of the structures are mutually displaced.

Reinforced concrete structures, as a rule, are statically indeterminate systems in which, with temperature changes, the development of shrinkage deformations, and uneven settlement of foundations, additional forces arise that can cause cracking. To reduce this kind of effort in buildings of great length, temperature-shrinkage and sedimentary seams are necessary.

Reinforced concrete structures, as a rule, are statically indeterminate systems in which, with temperature changes, the development of shrinkage deformations, and uneven settlement of foundations, additional forces arise that can cause cracking. To reduce this kind of effort in buildings of great length, temperature-shrinkage and sedimentary seams are necessary.

In coverings and ceilings of buildings, the distance between the seams depends on the flexibility of the columns and the flexibility of the joints; in monolithic structures, this distance should be less than in prefabricated ones. With the installation of rolling supports, thermal stresses can be generally avoided.

In addition, the distance between the expansion joints depends on the temperature difference; therefore, in heated buildings these distances are smaller regardless of all other factors.

Temperature-shrinkage joints cut structures from the roof to foundations, and sedimentary joints completely separate one part of the structure from another. The temperature-shrinkage seam can be formed by the device of paired columns on common ground. Sedimentary seams are provided in places of a sharp difference in the height of buildings, the junction of newly erected buildings with old ones during the construction of buildings or structures on soils of different composition and in other cases when uneven settlement of foundations is possible.

Sedimentary seams also form a device of paired columns, but installed on separate foundations.

|

|

|

Expansion joints: a - the building is separated by an expansion joint; b - the building is separated by a sedimentary seam |

Expansion joints: 1 - expansion joint; 2 - sedimentary seam; 3 - inset span of the sedimentary seam |

The distances between the temperature-shrinkage joints in concrete and reinforced concrete structures of low structures can be taken constructively, without calculation.

|

|

|

The device of sedimentary (deformation) seams along the perimeter of the building envelope: 1 - entrance group; 2 - decorative blind area; 3 decorative path made of outdoor stones; 4 - lawn; 5 - semi-closed drainage; 6 - blind area made of monolithic concrete; 7 - expansion joints with wooden bookmarks (short boards); 8 - wall of the house; 9 - semi-closed (open) drainage in the form of a tray; 10 - sedimentary (deformation) seam between the base of the house and the base entrance group; 11 - windows |

|

|

|

|

|

General view of the structure of the sedimentary (deformation) joint along section 1-1: 1 - pebbles (crushed stone, sand); semi-closed drainage (cut asbestos-cement pipe) resistant flat stones; 4 - pre-compacted base soil; 5 - sand cushion with a height of 8 to 15 cm; 6 - a layer of pebbles or crushed stone 5-10 cm; 7 - short board; 8 - pipe of closed bypass drainage; 9 - bed-bed stone; 10 - basement of the building; 11 - foundation; 12 - rammed base; 13 possible level of groundwater rise; 14 - a blind area made of monolithic concreteThe end of the form |

|

Sedimentary seams divide the building along the length into parts to prevent the destruction of structures in the event of a possible uneven settlement separate parts. Sedimentary joints run from the eaves of the building to the base of the foundation, the location of the joints is indicated in the project. The seams in the walls are made in the form of a sheet pile, as a rule, 1/2 brick thick, with two layers of roofing; and in the foundations - without tongue and groove. Above the upper edge of the foundation under the sheet pile of the wall, a gap of 1-2 bricks is left so that during the draft the sheet pile does not rest against the foundation masonry. Otherwise, the masonry may collapse in this place. Sedimentary seams in foundations and walls are caulked with tarred tow.

Sedimentary seams divide the building along the length into parts to prevent the destruction of structures in the event of a possible uneven settlement separate parts. Sedimentary joints run from the eaves of the building to the base of the foundation, the location of the joints is indicated in the project. The seams in the walls are made in the form of a sheet pile, as a rule, 1/2 brick thick, with two layers of roofing; and in the foundations - without tongue and groove. Above the upper edge of the foundation under the sheet pile of the wall, a gap of 1-2 bricks is left so that during the draft the sheet pile does not rest against the foundation masonry. Otherwise, the masonry may collapse in this place. Sedimentary seams in foundations and walls are caulked with tarred tow.

To superficial ground water did not penetrate into the basement through the sedimentary seam, with its outer side arrange a clay castle or apply other measures provided for by the project. Expansion joints protect buildings from cracks during thermal deformations.

Sedimentary seams are arranged at the junctions of building sections:

- located on heterogeneous soils;

- attached to existing buildings;

- with a difference in height exceeding 10 m;

- in all cases where uneven settlement of the foundation can be expected.

Sedimentary and temperature seams in brick walls should be made in the form of a tongue and groove with a groove size for walls with a thickness of 1.5 and 2 bricks - 13 x 14 cm, and for thicker walls 13 x 27 cm. In the rubble masonry of basement walls and foundations, the seams can be arranged through.

On device expansion joints of the coating the roofing carpet is best torn apart. Rolled rubber can be used as a vapor barrier in the design of the expansion joint.

|

|

|

Expansion joint |

Scheme of installation of a deformation-sedimentary joint between sections of a retaining wall |

In cases where the expansion joint is arranged at the watershed, and the movement of water flow along the seam is impossible, or the slopes on the roof are more than 15%, then it is permissible to use a simplified design of the expansion joint during the device. The deformations of the building are compensated by the upper mineral wool insulation.

In roofs with a corrugated sheet base, it is necessary to fix the main layers of roofing material at the edges expansion joint.

Thermal expansion joint with walls made of lightweight concrete or piece materials can be installed in roofs with a concrete base or from reinforced concrete slabs.

|

|

|

Simplified expansion joint design |

Expansion joint in roofs with corrugated sheet base |

The wall of the expansion joint is installed on the supporting structures. The edge of the wall of the TDSH should be 300 mm higher than the surface of the roofing carpet. The seam between the walls must be at least 30 mm.

A metal compensator installed in an expansion joint cannot serve as a vapor barrier. Additional layers required vapor barrier material to the compensator.

Temperature joint arrange in walls of great length to avoid the appearance of cracks from temperature changes. Such a seam cuts through structures only on the ground part, up to the foundations, because the foundations, being in the ground, do not experience temperature effects. The distance between these seams ranges from 20 to 200 m and depends on the material of the walls and the area of construction. The smallest joint width is 20 mm.

|

|

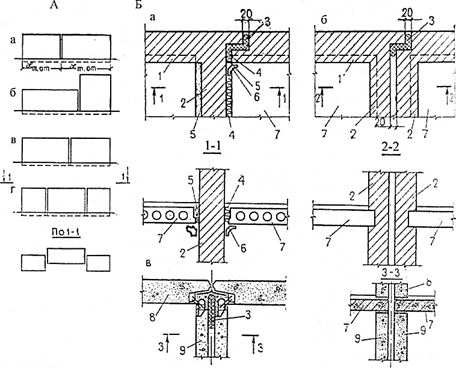

| The device of a temperature-strain joint in the partitions of the building: 1 - masonry of small cellular concrete blocks; 2, 3 - cellular concrete floor slabs; 4 - a seam with a heat-insulating plate (the presence of fragments of wall material and glue in the seam is unacceptable); 5 - seam in the foundation; 6 - reinforced belt along the perimeter of the building; 7 - reinforced concrete slab grounds; 8 - reinforced belt along the perimeter of the building with external thermal insulation; 9 - roof with thermal insulation according to the rules roofing works | Vertical expansion joint: 1 - outer facing plates; 2 - hydrowindproof layer; 3 - plaster system; 19 - profile for a vertical expansion joint; 23 - racks wooden frame; 30 - insulating material |

Sedimentary seam cuts the building to its full height - from the ridge to the base of the foundation. Such a seam is located depending on some factors:

with a height difference of the building not less than 10m;

if the soils that are used as a base have different bearing capacity;

during the construction of a building with a different erection period.

The smallest joint width is 20 mm

seismic seam suit in buildings that are built in seismic areas.

Scheme of placement and design of expansion joints: a - facade of the building; b - temperature or sedimentary seam with a groove and a crest; c - temperature or sedimentary seam in a quarter; d - expansion joint with a compensator; 1 - temperature seam; 2 - sedimentary seam; 3 - wall; 4 - foundation; 5 - insulation; 6 - compensator; 7 - roll insulation.

The designs of expansion joints should provide the possibility of moving the ends of the spans without overvoltage and damage to the elements of the joint, the rider's clothing, canvas and spans; must be water and dirt impervious (prevent water and dirt from entering the ends of the beams and support platforms); operable in the specified temperature ranges; have reliable anchoring in the span; prevent the penetration of moisture on the roadway slab and under the border (have a reliable waterproofing).

The designs of expansion joints should provide the possibility of moving the ends of the spans without overvoltage and damage to the elements of the joint, the rider's clothing, canvas and spans; must be water and dirt impervious (prevent water and dirt from entering the ends of the beams and support platforms); operable in the specified temperature ranges; have reliable anchoring in the span; prevent the penetration of moisture on the roadway slab and under the border (have a reliable waterproofing).

The material of constructions of expansion joints must resist wear, ular and abrasion, the effects of ice, snow, sand; should be relatively immune to the effects of sunlight, oil products, salts.

In general, expansion joints should be located:

- between the foundation and wall masonry using bituminous roll materials;

- between warm and cold walls;

- when changing the thickness of the wall;

- in unreinforced walls with a length of more than 6 m (longitudinal reinforcement of the walls makes it possible to increase the distance between expansion joints);

- when crossing long load-bearing walls;

- at the junctions with columns or structures made of other materials;

- in places of a sharp change in the height of the wall.

Sealing expansion joints

Expansion joints are sealed with mineral wool or polyethylene foam. From the side of the room, the seams are sealed with elastic vapor-tight materials, from the outside - with weather-resistant sealants or flashings. The cladding material must not overlap the expansion joint.

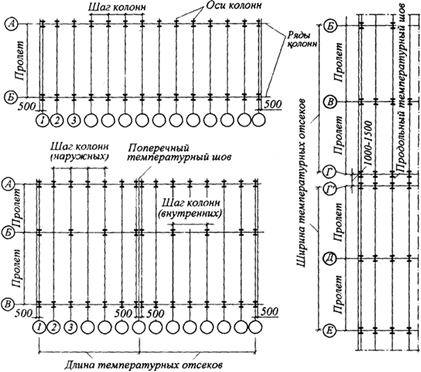

The dimensions of the temperature blocks are taken depending on the type and design of buildings. The largest distances (m) between expansion joints in frame buildings, which can be admitted without verification calculation.

except temperature deformations the building may give uneven settlement if it is located on inhomogeneous soils or in the case of a sharply different operational load along the length of the building. In this case, to avoid sedimentary deformations, arrange sedimentary seams. At the same time, the foundations are made independent, and in the above-ground part of the building, the sedimentary seam is combined with a temperature seam or with an abutment seam (adjacency of buildings of different heights, an old building to a new one). expansion joints arrange in walls and coverings in order to ensure the possibility of mutual displacement of adjacent parts of the building both in horizontal and vertical directions without disturbing thermal resistance seam and its waterproofing properties.

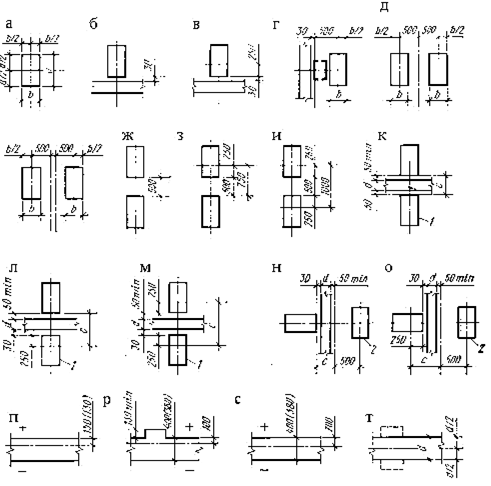

When arranging longitudinal expansion joints or height difference of parallel spans on paired columns, paired modular coordination axles with an insert between them should be provided. Depending on the size of the binding of columns in each of the adjacent spans, the dimensions of the inserts between the paired coordination axes along the lines of expansion joints in buildings with spans of the same height and with coverings along rafter beams (trusses) are taken equal to 500, 750, 1000 mm.

|

|

|

Anchoring columns and walls one-story buildings to the coordinate axes: a - binding of columns to the middle axes; b, c - the same, columns and walls to the extreme longitudinal axes; d, e, f - the same, to the transverse axes at the ends of buildings and places of transverse expansion joints; g, h, and - binding of columns in longitudinal expansion joints buildings with spans of the same height; k, l, m - the same, with a difference in heights of parallel spans, n, o - the same, with mutually perpendicular junction of spans; p, p, s, t - binding of load-bearing walls to longitudinal coordinate axes; 1 - columns of elevated spans; 2 - columns of low spans, which adjoin the ends to an increased transverse span |

|

The size of the insert between the longitudinal coordination axes along the line of height difference of parallel spans in buildings with roof beams (trusses) coatings must be a multiple of 50 mm:

- binding to the coordination axes of the faces of the columns facing the drop;

- wall thickness of panels and a gap of 30 m between its inner plane and the edge of the columns of an increased span;

- a gap of at least 50 mm between the outer plane of the wall and the edge of the low-span columns.

In this case, the size of the insert must be at least 300 mm. The dimensions of the inserts at the junction of mutually perpendicular spans (lower longitudinal to higher transverse) range from 300 to 900 mm. If there is a longitudinal seam between spans that are adjacent to a perpendicular span, this seam is extended into the perpendicular span where it will be a transverse joint. In this case, the insertion between the coordination axes in the longitudinal and transverse seams is 500, 750 and 1000 mm, and each of the paired columns along the line of the transverse seam must be displaced from the nearest axis by 500 mm. If the coating structures are supported on the outer walls, then the inner plane of the wall is shifted inward from the coordination axis by 150 (130) mm.

Columns to the average longitudinal and transverse coordination axes multi-storey buildings tied so that the geometric axes of the section of the columns coincide with the coordination axes, with the exception of the columns along the lines of expansion joints. In the case of binding columns and external walls made of panels to the extreme longitudinal coordination axes of buildings, the outer edge of the columns (depending on the frame design) is shifted outward from the coordination axis by 200 mm or aligned with this axis, and a gap of 30 is provided between the inner plane of the wall and the faces of the columns. mm. Along the line of transverse expansion joints of buildings with ceilings made of prefabricated ribbed or smooth hollow core slabs provide paired coordination axes with an insert between them with a size of 1000 mm, and the geometric axes of the paired columns are combined with the coordination axes.

In the case of an extension of multi-storey buildings to one-story buildings, it is not allowed to mix the coordination axes perpendicular to the extension line and common to both parts of the interlocked building. The dimensions of the insert between the parallel extreme coordination axes along the extension line of buildings are assigned taking into account the use of standard wall panels- elongated ordinary or additional.

If there are expansion joints of double walls in places of expansion joints, double modular centering axes are used, the distance between which is taken equal to the sum of the distances from each axis to the corresponding wall face with the addition of the joint size.

A common option for floors of buildings, structures and coatings in industrial premises with intense mechanical stress is a concrete floor. The material from which these structural elements are made is subject to shrinkage and has a low resistance to deformation, as a result of which cracks occur. In order to avoid repeated repairs, artificial cuts are created in, for example, an expansion joint in concrete floors, in building walls, roofs, bridges.

What are they needed for?

The concrete floor appears to be a strong and durable base. However, under the influence of temperature fluctuations, shrinkage processes, air humidity, operational loads, soil sedimentation, its integrity is lost - it begins to crack.

To give some degree of elasticity to this building structure, expansion joints are created in the concrete floors. SNiP2.03.13-88 and its Manual contain information on the requirements for the design and installation of floors, indicating the need for a break device in the screed, underlying layer or coating, which provides a relative displacement of disparate sections.

Main functions:

- Minimization of sudden deformations, through division monolithic slab on the a certain amount of kart.

- The ability to avoid costly repairs with the replacement of the rough and basic coating.

- Increasing resistance to dynamic loads.

- Ensuring the durability of the structural basis.

Main types: insulating seam

In concrete floors, depending on its purpose, it is divided into three types: insulating, structural and shrinkage.

Insulating cuts are made at the junction of the structural elements of the room. That is, they are an intermediate seam between walls, columns and floors. This makes it possible to avoid cracks during shrinkage of concrete in the places where the horizontal and vertical elements of the room fit. If we neglect their arrangement, then the screed, when dried and reduced in volume with a rigid adhesion to the wall, for example, is most likely to crack.

An insulating joint is created along walls, columns and in places where the concrete floor borders with others. Moreover, a seam is cut near the columns not parallel to the faces of the columnar element, but in such a way that a straight cut falls on the corner of the column.

The considered type of seam is filled capable of allowing horizontal and vertical movement of the screed relative to the foundation, columns and walls. The thickness of the joint depends on the linear expansion of the screed and is about 13 mm.

Main types: shrink seam

If the insulating joints prevent deformation of the monolithic concrete floor at the points of contact with the walls, then shrinkage cuts are necessary to prevent random cracking of the concrete over the entire surface. That is to prevent damage caused by shrinkage of the material. As the concrete dries from top to bottom, tension appears inside it, created by the hardening of the top layer.

The device of expansion joints in concrete floors of this type occurs along the axes of the columns, where the cuts are joined to the corners of the joints along the perimeter. Cards, that is, parts of a monolithic floor, limited on all sides by shrinkage seams, should be square, L-shaped and elongated rectangular shapes should be avoided. The work is carried out both during the laying of concrete with the help of forming rails, and by cutting the seams after the screed has dried.

The probability of cracking is directly proportional to the size of the cards. How less area floor, limited by shrinkage joints, so the likelihood of cracking is minimal. The sharp corners of the screed are also subject to deformation, therefore, in order to avoid concrete ruptures in such places, it is also necessary to cut shrinkage-type seams.

Main types: construction seam

Such protection of monolithic floors is created when it occurs at work. The exceptions are rooms with a small area of pouring and continuous supply of concrete. An expansion joint in concrete floors of a structural type is cut at the joints of the screed, made at different times. The shape of the end of such a connection is created according to the "thorn-groove" type. Features of structural protection:

- The seam is arranged at a distance of 1.5 m parallel to other types of deformation demarcations.

- It is created only if concrete is laid at different times of the day.

- The shape of the ends should be made according to the "thorn-groove" type.

- For a screed thickness of up to 20 cm, a 30-degree cone is made on the wooden side protrusions. Metal cones are allowed.

- Tapered seams protect the monolithic floor from minor horizontal movements.

Expansion joints in concrete floors of industrial buildings

Increased wear resistance requirements are imposed on floors laid in factories, warehouses and other industrial facilities. This is due to the appearance of the influence of different intensity of mechanical action (movement Vehicle, pedestrians, impact from falling solid objects) and possible spillage of liquid on the floor.

Usually, design feature floor is a screed and coating. But under the screed there is an underlying layer, which in a rigid design is laid out of concrete. A seam is cut in it in mutually perpendicular directions through 6-12 m, with a depth of 40 mm, with at least 1/3 of the thickness of the underlying layer (SNiP 2.03.13-88). A prerequisite is the coincidence of the expansion joint of the floor with similar protective gaps in the building.

A distinctive feature of the structure of floors in industrial buildings is the creation of a top layer of concrete. Depending on the intensity of mechanical action, coatings of different thicknesses are designed. With a thickness of 50 mm or more, a deformation joint in concrete floors (SNiP "Floors" clause 8.2.7) is created in the transverse and longitudinal direction with the repetition of elements every 3-6 m. less than 40 mm or a third of the coating thickness.

Requirements for creating deformation floor protection

Concrete must be cut with a cutter after two days of hardening. The depth of cuts according to the norms is 1/3 of the concrete thickness. In the underlying layer, it is allowed to use slats treated with anti-adhesion compounds in places of alleged gaps before pouring concrete, which are removed after the material has hardened and as a result protective seams are obtained.

The lower parts of the columns and walls to the height of the future thickness of the coating should be glued with roll waterproofing materials or foamed sheet polyethylene. In those places where the project provides for expansion joints in concrete floors. Cutting technology begins with marking with chalk and a ruler of artificial breaks.

A test joint serves as an indicator of timely cutting: if the grains of the aggregate do not fall out of the concrete, but are cut by the cutter's blade, then the time for creating expansion joints is chosen correctly.

Seam processing

The normal functioning of the seam is achieved by sealing it. Sealing expansion joints in concrete floors is carried out using the following materials:

- A waterstop is a profiled tape made of rubber, polyethylene or PVC, which is laid when pouring a concrete screed;

- The sealing cord made of foamed polyester is laid in the slot and retains its elasticity during temperature changes, ensuring safe movement. concrete pavement;

- Acrylic, polyurethane, latex mastic;

- Deformation profile, consisting of rubber and metal guides. It can be built-in or overhead.

Before sealing, the working surface of the gaps must be cleaned and blown with compressed air (compressor). Also, to increase the service life of concrete floors, it is desirable to strengthen upper layer topping or polyurethane material.

Creation conditions

The expansion joint in becomes mandatory under the following conditions:

- Screed, total area above 40 m2.

- Complex floor configuration.

- Operation of the floor covering at elevated temperatures.

- The length of the rib (one is enough) of the floor structure is more than 8 m.

Expansion joints in concrete floors: norms

In conclusion, the requirements for the installation of protective gaps in concrete floors according to the norms are given.

The underlying layer should have deformation cuts perpendicular to each other with a step of 6 to 12 meters. The seam is 4 cm deep and is one third of the thickness of the concrete pavement or sub-base.

With a concrete coating thickness of 50 mm or more, a deformation joint is created in the transverse and longitudinal directions with a repetition every 3-6 m. These cuts must coincide with the seams of the floor slabs, the axes of the columns, and the expansion gaps in the underlying layer. The cutting width is 3-5 mm.

The cut is carried out two days after the concrete is laid. Protective cuts are sealed with special cords and sealants.

Any structural element buildings in the process of its work in the structure carries a certain power load. Moreover, it is not always associated with seismic vibrations or the weight of the building as such. The very problem of building physics has for a long time been an uneven expansion different materials when heated and contraction when cooled.

For instance:

The coefficients of thermal expansion of metal and wood differ several times. This justifies mechanical failure. wooden beams located in a cold under-roof space, which are fixed with ordinary studs and fittings without thermal break. To solve this and some other problems in general construction practice, the device of expansion joints is used.

Below we give full list problems when this element "works" and helps to maintain the structural integrity of the entire building:

- seismic activity of the earth's crust;

- soil settlement, groundwater rise;

- force deformations;

- sudden change in ambient temperature.

Depending on the nature of the problem being solved, all expansion joints are divided into temperature, shrinkage, seismic and sedimentary.

Temperature expansion joint

Structurally expansion joint is a section that divides the entire structure into sections. The size of the sections and the direction of division - vertical or horizontal - is determined by the design decision and the power calculation of static and dynamic loads.

To seal the cuts and reduce the level of heat loss through expansion joints, they are filled with an elastic heat insulator, most often these are special rubberized materials. Thanks to this separation, the structural elasticity of the entire building increases and the thermal expansion of its individual elements does not have a devastating effect on other materials.

As a rule, the temperature expansion joint runs from the roof to the very foundation of the house, dividing it into sections. It does not make sense to divide the foundation itself, since it is below the freezing depth of the soil and does not experience such negative impact like the rest of the building. The step of the expansion joints will be influenced by the type of applied building materials And geographic location object that determines the average winter temperature.

In statically indeterminate systems reinforced concrete buildings and structures, in addition to efforts from external loads additional forces arise as a result of changes in temperature and concrete shrinkage. In order to limit the magnitude of these efforts, temperature-shrinkage seams are arranged, the distances between which are determined by calculation.

It is allowed not to do the calculation for structures of the 3rd category of crack resistance at calculated low ambient temperatures above minus 40 ° C, if the distances between the expansion joints do not exceed the required values \u200b\u200bgiven in the SNiP table. In any case, the distance between the seams must be no more than:

150 m for heated prefabricated buildings;

90 m - for heated buildings from prefabricated monolithic and monolithic structures.

For unheated buildings and structures, these values must be reduced by at least 20%. To prevent the occurrence of additional forces in case of uneven subsidence of the base (sections of different heights, difficult soil conditions, etc.), settlement joints are provided.

Attention should be paid to the fact that sedimentary joints cut through the structure to the base, and temperature-shrinkage joints - only to the top of the foundations. Sedimentary seams at the same time play the role of temperature-shrinkage seams.

Schemes of expansion joints

The width of the temperature-shrinkage joint is usually 2 ... 3 cm, it is specified by calculation depending on the length of the temperature block and the temperature difference.

Main points in the problem of temperature calculation

Expert opinion.

Uncertainty with the stiffness characteristics of the base in the horizontal direction - for example, given the rate of application of the thermal load, there can be a fair amount of rheology. The friction against the ground will be different in different sections of the foundation, depending on the pressure on the ground in these areas. Local damage to waterproofing - can there be and should they be taken into account? What about local plastic zones in soils? Well, plus, the backfill I mentioned. Variation of the rigidity characteristics of the base in the horizontal direction can repeatedly change the forces from temperature loads. With piles it is still more difficult.

The non-linearity of reinforced concrete, its sufficiently "long" stiffness characteristics - what will be the change in the deformation diagram of reinforced concrete at a loading rate that is different for temperature loads? I am already silent about all the other subtleties of modeling the nonlinear properties of reinforced concrete - at least it is necessary to model with solids in order to take into account the reduction in shear stiffness of all elements, especially massive ones, which are concentrators.

Uncertainty with the temperature loads themselves. In reinforced concrete, even without these loads, numerous cracks will open, and even more so taking into account the temperature. And not only the rigidity of the frame will decrease, but also the loads themselves, because. the area of the elements itself decreases (due to the formation of cracks), which is not taken into account by the methods known to me.

Thus, I believe that a full-fledged temperature calculation of reinforced concrete frames is currently a fortune-telling, and the only thing you need to believe is design experience, reflected in particular in the recommended distances between temperature blocks.

Sedimentary expansion joint

The second important area of application expansion joints is the compensation of uneven pressure on the ground during the construction of buildings with a variable number of storeys. In this case, the higher part of the building (and therefore heavier) will press on the ground with more force than the lower part. As a result, cracks can form in the walls and foundation of the building. A similar problem can be soil settlement within the area under the foundation of the building.

To prevent cracking of the walls in these cases, sedimentary expansion joints are used, which, unlike the previous type, divide not only the building itself, but also its foundation. Often in the same building there is a need to use different types of seams. Combined expansion joints are called temperature-sedimentary.

Anti-seismic expansion joints

As their name implies, such seams are used in buildings located in seismically hazardous zones of the Earth. The essence of these seams is to divide the entire building into "cubes" - compartments that are themselves stable containers. Such a "cube" should be limited by expansion joints on all sides, along all faces. Only in this case the anti-seismic seam will work.

Along the anti-seismic joints, double walls or double rows of supporting columns are arranged, which are the basis load-bearing structure each individual compartment.

Shrink expansion joint

Shrink expansion joints are used in monolithic concrete frames, since concrete, when hardened, tends to decrease somewhat in volume due to water evaporation. Shrinkage seam prevents the occurrence of cracks that violate the load-bearing capacity monolithic frame.

The meaning of such a seam is that it expands more and more, parallel to the hardening of a monolithic frame. After the hardening is over, the resulting deformation seam is completely minted. To give hermetic resistance to shrinkage and any other expansion joints, special sealants and waterstops are used.

During the construction and design of structures for various purposes a expansion joint is used, which is necessary to strengthen the entire structure. The task of the seam is the safety of the structure from seismic, sedimentary and mechanical influences. This procedure serves as an additional strengthening of the house, protects against destruction, shrinkage and possible shifts and distortions on the soil.

Definition of an expansion joint and its types

Expansion joint- a section on the structure, which reduces the load on parts of the structure, which increases the stability of the building and the level of its resistance to loads.

It makes sense to use this stage of construction when designing large premises, placing a building in places weak ground, active seismic phenomena. The seam is also made in areas with high rainfall.

Based on the purpose, expansion joints are divided into:

- temperature;

- shrinkage;

- sedimentary;

- seismic.

In some buildings, due to the peculiarities of their location, combinations of methods are used to protect against several causes of deformation at once. This can be caused when the terrain on which the construction is being built has soil that is prone to subsidence. It is also recommended to make several types of seams when building long tall houses, with many various designs and elements.

Temperature joints

These construction methods serve as protection against temperature changes and fluctuations. Even in cities located in areas with temperate climate during the transition from high summer temperatures to low winter temperatures, cracks of various sizes and depths often appear on houses. Subsequently, they lead to deformation not only of the box of the structure, but also of the base. To avoid these problems, the building is divided by seams, at a distance which is determined based on the material from which the structure was erected. It also takes into account the maximum low temperature characteristic of this area.

Such seams are used only on the wall surface, since the foundation, due to its location in the ground, is less susceptible to temperature changes.

Shrink seams

They are used less often than others, mainly when creating a monolithic concrete frame. The fact is that concrete during hardening is often covered with cracks, which subsequently grow and create cavities. In the presence of a large number cracks in the foundation, the structure of the building may not withstand and collapse.

The seam is applied only until the foundation has completely hardened. The meaning of its use is that it grows until all the concrete becomes solid. In this way, concrete foundation completely shrinks, without being covered with cracks.

After the final drying of the concrete, the cut must be completely minted.

To ensure that the seam is completely sealed and does not let moisture through, special sealants and waterstops are used.

Sedimentary expansion joints

Such structures are used in the construction and design of structures of different heights. So, for example, when building a house, in which there will be two floors on one side and three on the other. In this case, that part of the building with three floors exerts much more pressure on the soil than the one with only two. Due to uneven pressure, the soil can sag, thereby causing strong pressure on the foundation and walls.

From the change in pressure, the various surfaces of the structure are covered with a network of cracks and subsequently subjected to destruction. In order to prevent deformation of structural elements, builders use a sedimentary expansion joint.

Strengthening divides not only the walls, but also the foundation, thereby protecting the house from destruction. It has a vertical shape and is located from the roof to the base of the structure. Creates a fixation of all parts of the structure, protects the house from destruction, deformation of varying severity.

Upon completion of the work, it is necessary to seal the recess itself and its edges to fully protect the structure from moisture and dust. For this, ordinary sealants are used, which can be found in hardware stores. Work with materials is carried out according to general rules and recommendations. An important condition the arrangement of the seam is its complete filling with material so that there are no voids inside.

On the surface of the walls, they are made of tongue and groove, with a thickness of about half a brick; in the lower part, the seam is made without a shunt.

In order to prevent moisture from getting inside the building, a clay castle is equipped on the outside of the basement. Thus, the seam not only protects against the destruction of the structure, but also turns out to be an additional sealant. The house is protected from groundwater.

This type of seams must be arranged at the points of contact of various sections of the building, in such cases:

- if parts of the building are placed on soil of different flowability;

- in the event that others are added to an existing structure, even if they are made of identical materials;

- with a significant difference in the height of individual parts of the building, which exceeds 10 meters;

- in any other cases where there is reason to expect uneven subsidence of the foundation.

seismic seams

Such structures are also called anti-seismic. It is necessary to create this kind of fortification in areas with an increased seismic nature - the presence of earthquakes, tsunamis, landslides, volcanic eruptions. So that the building does not suffer from bad weather, it is customary to build such fortifications. The design is designed to protect the house from destruction during earth tremors.

Seismic seams are designed according to their own scheme. The meaning of the design is the creation of separate non-communicating vessels inside the building, which will be separated along the perimeter by expansion joints. Often inside the building, expansion joints are arranged in the form of a cube with equal sides. The faces of the cube are sealed with a double brickwork. The design is designed for the fact that at the time of seismic activity, the seams will hold the structure without allowing the walls to collapse.

The use of various types of seams in construction

With temperature fluctuations, structures made of reinforced concrete are subject to deformation - they can change their shape, size and density. When concrete shrinks, the structure shortens and sags over time. Since subsidence occurs unevenly, when the height of one part of the structure decreases, the others begin to shift, thereby destroying each other or forming cracks and depressions.

Nowadays, each reinforced concrete structure is an integral indivisible system, which is highly susceptible to changes in the environment. So, for example, during the settlement of the soil, sharp fluctuations in temperature, sedimentary deformations between the parts of the structure, there is a mutual extra pressure. Constant changes in pressure lead to the formation of various defects on the surface of the structure - punctures, cracks, dents. To avoid the formation of defects in the building, the builders use several types of cuts, which are designed to strengthen the building and protect it from various destructive factors.

In order to reduce the pressure between the elements in multi-storey or extended buildings, it is necessary to use sedimentary and temperature-shrinkage types of seams.

In order to determine the required distance between the seams on the surface of the structure, the level of moisture content of the material of the columns and connections is taken into account. The only case when there is no need to install expansion joints is the presence of rolling supports.

Also, the distance between the seams often depends on the difference between the highest and lowest ambient temperatures. The lower the temperature, the farther apart the recesses should be. Thermal shrinkage joints permeate the structure from the roof to the base of the foundation. While sedimentary isolate different parts of the building.

A shrinkage joint is sometimes formed by installing several pairs of columns.

The temperature-shrinkage joint is usually formed by arranging paired columns on a common foundation. Sedimentary seams are also designed by installing several pairs of supports that are opposite each other. In this case, each of the support columns must be equipped with its own foundation and fasteners.

The design of each seam is designed to be clearly structured, securely fix the elements of the structure, be reliably sealed from Wastewater. The seam must be resistant to temperature extremes, the presence of precipitation, resist deformation from wear, shock, mechanical stress.

Seams must be made in case of uneven ground, uneven height of the walls.

The expansion joints are insulated with mineral wool or polyethylene foam. This is due to the need to protect the premises from cold temperatures, the penetration of dirt from the street, and additional sound insulation is provided. Other types of heaters are also used. From the inside of the room, each seam is sealed with elastic materials, and from the side of the street - with sealants that can protect against atmospheric precipitation or flashings. The cladding material does not cover the expansion joint. At interior decoration the seam is covered with decorative elements at the discretion of the builder.