What is cork flooring. Which is better to buy a cork floor: glued or floating

Cork - what is this material? Everyone knows that it is used to cork wine bottles, to make do-it-yourself winter fishing rods, and in the manufacture of shoes. However, little is known about cork as a building material. Cork- a novelty in the field of floor finishing, about which disputes do not subside, since the material is exotic and by no means cheap. What are the pros and cons of cork flooring? What is this coating better than laminate? Does it apply in your kitchen and bathroom?

Cork is the bark of the cork oak, which grows in Mediterranean countries with a warm and humid climate. The most extensive plantations of this oak are in Spain and Portugal, so these countries are the world leaders in the processing of cork and the production of building materials from it. Grow a tree and Asian countries ah, but due to different from the Mediterranean climatic conditions, the quality of, for example, Chinese cork is worse.

Cork floors are divided into three types:

- adhesive;

- Castle;

- Technical.

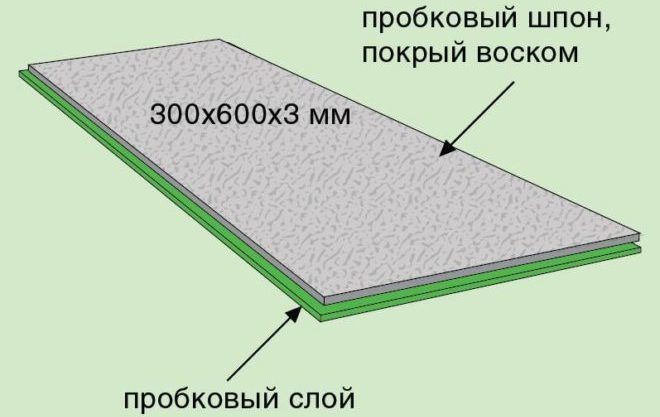

Floors that require an adhesive base are completely natural. They are solid pressed panels of different sizes (30x30, 45x15, 45x45, 60x30), their thickness is from 4 to 6 mm. Two-layer tiles:

- Bottom - pressed cork chips,

- Top - high grade veneer.

Cork coating of this type is highly moisture resistant, tolerates temperature fluctuations due to impregnation special composition. As a rule, adhesive cork floors are used in the hallway, bathroom, toilet, balcony and kitchen.

Such a coating is a creative space for designers. Using cork in different shades, any mosaic can be applied to the floor and thus create a completely unique finish.

Laying the floor requires a carefully prepared base. It should be level and free of debris. The panels do not require a substrate and are attached to the usual universal adhesive.

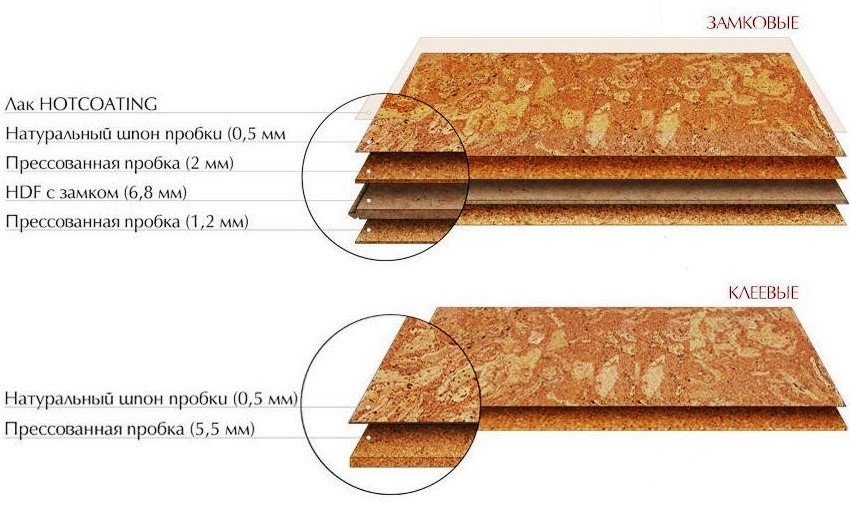

Castle floors are called cork laminate. This is a multilayer material in which there is an agglomerate on the bottom (a cork coating of compressed crumbs), in the middle - MDF, and on top - a cork veneer or several more layers of agglomerate. The total thickness of the plate can reach 12 mm, dimensions - 90x18.5 cm.

Like conventional laminate, cork flooring is equipped with locks, which greatly simplifies the installation process. No adhesive base or sealants are required, only a 2-3 mm backing. After the floor is laid, it is covered with several layers of varnish. As a rule, cork flooring manufacturers recommend compounds that are best applied.

Technical cork floors are not used for finishing floors, as they are nothing more than the remnants of production. Technical coating Cork is produced in plates, rolls or granules. Their main purpose is to fill the defects of the base or the substrate under the laminate.

Cork Benefits

Even though the cork floor more expensive than linoleum and laminate, the material is very advantageous. To appreciate its attractiveness, it is necessary to consider the advantages and disadvantages of cork flooring.

- Cork is absolutely eco-friendly. Natural is not only the material, but also the method of its extraction, while the tree does not suffer.

- The coating is antistatic. Thanks to this, the surface does not attract dust, which is very important in the kitchen, as well as for small children and people with allergies.

- Safe for human health. Does not emit harmful substances when heated.

- Prevents the formation of mold and fungus, which is a fairly common problem in the bathroom.

- It has good sound insulation. Isolates noise not only on the floor, but also when used on walls and ceilings. Even recording studios use cork material. If something falls on the cork floor, there will be no rumble.

- The cork floor is pleasant to walk barefoot. It is very soft and holds heat well. Under such a coating, it is not necessary to install a "warm floor" system.

- Useful for people with musculoskeletal problems. Judging by the reviews, the elastic cork floor springs when walking, reducing the load on the body. And the lack of slip will be indispensable for the elderly.

- Cork flooring is easy to install. The principle of installation of the coating is the same as that of a laminate with locks. Adhesive boards do not require special skills and tools.

The technology of laying cork on the floor is available to anyone home master

The technology of laying cork on the floor is available to anyone home master - Easy care. The surface can be vacuumed, wiped with a damp cloth. Solvents and cleaning materials with a hard surface should be avoided.

- Strength and durability. The honeycomb surface structure reduces friction and external impact. The cork floor will last about 10 years;

- The interlocking cork floor can be used immediately after installation. But for safety, it is recommended to impregnate the surface with a special protective substance.

- The ability to create any pattern on the floor, even consisting of several colors.

- The ability to get rid of skirting boards and thresholds. You can create a monolithic floor or tightly attach it to a coating of another material.

- There is no need to leave gaps between the coating and the wall.

- There is a choice of the degree of gloss of the surface. For the glue plug, a finishing varnish is required, which can be either matte or glossy.

- It perfectly tolerates temperature changes, which cannot be said about the laminate. Therefore, it is suitable for cottages and balconies.

The structure of the surface in the form of honeycombs will help to avoid slipping during wet rooms

The structure of the surface in the form of honeycombs will help to avoid slipping during wet rooms Coating Disadvantages

Despite its numerous advantages, cork flooring is not without its drawbacks, including:

- Pretty high price. Adhesive cork flooring is more expensive than a ready-made castle floor. But due to simple installation, the cost is much lower than that of parquet.

- Low moisture resistance. But this minus is eliminated with the help of additional wax impregnation.

- A critical drawback is flammability and vulnerability to external influences. Under heavy furniture, the cork bends, leaving traces of furniture legs. Therefore, it is recommended to install gaskets in such places that will reduce the load on the floor.

- Adhesive cork flooring, unlike laminate, is quite difficult to install with your own hands. Required.

- On the adhesive cork floor, you can not immediately walk and arrange furniture. Operation of the floor is possible in a day, only the complete drying of the varnish.

- Cork does not tolerate direct sunlight. With long and intense sunlight, natural decorative elements fade over time.

- Difficult to remove adhesive. If the plates are glued to the screed, then it will be problematic to tear them off, because a very strong glue is used.

The text discusses in detail such a type of material as cork flooring. From the article you can find out what this type of finish is, what properties and characteristics it has, and also evaluate the feasibility of using natural coverage in the interior, having studied its advantages and disadvantages, consumer reviews, average prices and other factors.

Cork flooring is made from porous oak bark. The extraction of this material does not negative impact on nature. The place where the bark was cut continues to grow and renew, which allows this procedure to be performed every 9 years without jeopardizing the condition of the tree. For the production of flooring, raw materials from 25-year-old oaks are used. Younger trees are not suitable for this. The most valuable is the bark cut from 150-year-old oaks.

As the basis for the coating, a mixture consisting of pressed bark is used. As a result of a special treatment inside the furnace, the material is saturated with air. In this case, natural juice contained in micropores is used. It's called suberin. At the next stage, the material is given strength. For the so-called reinforcement, resins and wood dust are used, which are added in several layers.

The finish layer is made of cork or other materials such as veneer or PVC. The scope of flooring, as well as their service life, depends on the properties and characteristics of the top coating.

To protect the coating from wear, as well as to give it a certain design, manufacturers use veneer in combination with cladding with other materials:

- veneer - the thickness of the layer is only 0.5 mm. The coating is applied over the base to the adhesive composition;

- cork floor lacquered veneer - the lacquer composition increases the life of the finish, which is ideal for living rooms including bedrooms;

- veneer covered with a protective vinyl film - it prevents scratches and also prevents moisture from entering the material. Thanks to this, the manufacturer's warranty extends to 10 years;

- veneer made from precious woods and covered with a vinyl film - the material is a natural veneer made from expensive woods. For protection purposes, it is covered with a layer of vinyl.

Note! Thanks to modern technology, consumers can buy cork flooring in any design. The photo printing method allows you to apply a realistic imitation of grass, wood, sand, stone, etc. to the surface of the material.

Cork flooring: material advantages

Cork used as a floor covering has many useful properties. This finishing material is lightweight compared to other types of coatings. Cork is characterized by sound impermeability. The material does not transmit noise, so it is suitable even for recording studios. At the same time, the finish has a low level of thermal conductivity, so that the heat of the room does not go to the floor, but is stored inside.

The surface of the cork is elastic and soft. Orthopedic specialists recommend using this type of finish for people with diseases of the musculoskeletal system, as well as as a coating in children's rooms. Cork is safe and environmentally friendly. Its surface does not slip, does not absorb liquids and does not emit harmful substances. In addition, the material has antistatic properties. The cork does not need complex care and perfectly repels dust.

The coating is resistant to liquids and chemicals. The exception is caustic solutions of alkaline origin. Cork does not interfere natural circulation air. Due to this, the material does not contribute to the growth of bacteria and the exacerbation of allergic reactions in the residents of the house. Cork is not subject to decay. She is not afraid of moisture. If the floors in the house get wet as a result of flooding, the coating will not deteriorate under the influence of the liquid, but provided that the surface has a protective treatment.

Cork is not afraid of temperature changes and is not subject to fading in the sun. Unlike laminate, this material can be laid on loggias and balconies. open type. This type of coating is very strong and durable. Due to its porous structure, the material reduces the level of friction, therefore, the aggressiveness of external influence factors is reduced.

Cons of cork floors

Like any other type of flooring, cork floors have both advantages and disadvantages. Due to its softness, the coating eventually sags under the weight of the furniture. Especially for bathrooms, manufacturers produce plates with a thickness of 1-1.2 cm. The size of such products is 14.8x14.8 cm. If the coating in the bathroom is thinner, there is a possibility that the bath will pierce it through.

Do not walk indoors in rubber-soled or high-heeled shoes, otherwise marks will remain on the surface of the coating. Also, do not lay mats made of latex or rubber on the floor. The trace of these products after a long stay is practically not removed.

Helpful advice! The pits left by chair legs and light furniture will even out on their own. For heavy furnishings, it is advisable to buy soft felt pads that will reduce pressure.

Significant disadvantages include the price of a cork floor. Moreover, the adhesive type of coating will cost much more than cork laminate. On the other hand, due to the simplified installation of interlocking plates, the costs of purchasing the material are partially compensated. As a result, the total cost of coating will be lower than that of natural parquet.

Another disadvantage of cork is flammability. The material itself is not combustible. The flammable component of the floor is its protective coatings, such as paint, varnish, glue. Natural coating has a low level of resistance to moisture. This disadvantage can be eliminated with varnish, sealant or wax impregnation.

Some flooring options (for example, adhesive-type floors) have a complex installation system. Only specialists can provide high-quality performance of such work. In addition, it is impossible to install the underfloor heating system under the cork floor. The material has a high degree of thermal insulation, so heat flows cannot enter the room.

Pros and cons of cork floors, photos, prices for various types of coverage

Manufacturers produce three types of cork that are used as flooring:

- solid veneer - the material consists of solid pieces of wood bark (this type of finish has high price and is used for decorating ceiling and wall surfaces, as well as niches);

- glomerate - the material looks like sheets, consisting of crushed bark, joined together by gluing (this type of finish is practical and affordable);

- combined cork - consists of agglomerate and veneer, they are glued together under high pressure.

For the production of combined cork, veneer is used that is not suitable for the manufacture of plates. As a result, the finish acquires a decorative appearance and a beautiful texture. Combined cork goes well with other materials.

There are the following types of coatings:

- Floating or castle floor.

- Adhesive floor.

- Technical traffic jam.

They have different properties and are characterized by a specific scope.

Features of cork tiles for interlocking floors

The floating floor consists of slabs interconnected by interlocking joints. The thickness of these panels varies between 10.5-12 mm. The size of the tile is 18.5x90 cm. The finish is laid in the same way as a conventional laminate.

For the manufacture of the base of these plates, crushed crumb is used. As finish coat wood or cork is used, which is covered with a layer of paint and a printed image. This type of finish is desirable to use in well-heated rooms, where there are no temperature differences. Sudden changes can adversely affect the condition of the interlocks.

Important! When buying plates, be sure to pay attention to the quality of the interlocks. The integrity of the coating and its durability depend on them.

It is not recommended to use cork floating floors in areas with high traffic, such as walk-through corridors or kitchens. The installation system of the coating is quite simple. If one of the fragments is damaged during operation, a whole row will have to be disassembled. The area from the wall to the place where the defective element is located is subject to dismantling.

There is a moisture resistant cork board on the floor (laminate). The base in this material is a slab made of quartz and PVC. This type of coating has a higher price, while the choice of colors is limited.

Related article:

Parameters affecting the choice. Properties of various materials. Features of the floor different rooms. Additional floor modifications.

Cost of floating cork floors: price per meter of finish

Leading manufacturers and suppliers of cork flooring are Spain and Portugal, where porous oaks are widely distributed. Products from Asian countries are in lower demand, since the climatic conditions of this region do not allow growing high quality wood.

Average cost per 1 m² of Wicanders floating cork floors:

| Collection name | Price, rub./m² |

| Originals | 1650 |

| Identity | 2150 |

| Personality | 2150 |

| Cork Veneers | 2220 |

| character | 2280 |

| Linn | 2390 |

| Cork Plank | 2450 |

| Homecork | 2490 |

| Artcomfort Wood | 2500 |

| Artcomfort Stone | 2550 |

Features and specifications of adhesive cork floors

The adhesive floor consists of cork panels with an additional protective coating. The thickness of these elements is 4-6 mm. The material has a two-layer structure. At the bottom there is pressed cork chips, and the finishing layer on the panels is veneer. Elements can be either rectangular (60x30 and 45x15 cm) or square (40x40 and 30x30 cm). This type of coating is suitable for rooms with a high level of humidity, such as bathrooms and kitchens.

Before installation, you need to carefully prepare the surface. The base for the installation of the coating must be perfectly flat. Glue is used to fix the panels. In order for the result of laying the coating to be of high quality and durable, all elements must be carefully adjusted. Backlashes are not allowed.

With the help of this material on the floor, you can create decorative ornaments and patterns. When the installation is completed, the cork is coated with a polyurethane-based varnish in several layers. Be sure to process the gaps between the modular elements.

Helpful advice! If one of the fragments is damaged, do not dismantle the entire coating. It is enough to cut out the damaged bar and replace it with a new one.

Average cost of adhesive cork floors: price per m2

The main criterion for choosing flooring is the manufacturer. The following manufacturers are considered the most popular and best on the market:

- Wicanders;

- corkstyle;

- Allied Cork.

average price cork flooring Wicanders:

| Collection name | Price, rub./m² |

| Cork Parquet | 1230 |

| Eco Cork | 1340 |

| Crackle | 1400 |

| Nuances | 2000 |

| Personality | 2050 |

| Identity | 2050 |

| exotic | 3700 |

What is the purpose of installing a technical cork on the floor

Technical cork is made from the remnants of production. Therefore, it is not used as a floor finish. The main function of this material is to eliminate defects by filling (granules) or preparing the surface for laying the laminate. In the second case, the cork cloth is used as a substrate that levels the base.

Technical material is available in several forms:

- Granules.

- Rolls.

- Plates.

Besides, technical material used to create additional sound and thermal insulation.

Technical cork cost:

| The form | Size, cm | Material thickness, mm | Price, rub./m² |

| Roll | 100x1000 | 2 | 104 |

| 3 | 163 | ||

| 100x2500 | 4 | 235 | |

| plate | 91.5x61 | 4 | 323 |

| 6 | 464 | ||

| 8 | 547 | ||

| 10 | 666 |

Which is better to buy a cork floor: glued or floating

Adhesive and lock floors differ from each other not only in their structure, but also in their properties.

The adhesive floor panel consists of the following components:

- bases from compressed agglomerate obtained by gluing;

- wood veneer as a decorative coating;

- a thin layer of varnish or protective vinyl flooring, which give the panel a matte or glossy surface.

Advantages of adhesive coating:

- It is not afraid of the influence of humidity and temperature changes, as well as contact with water.

- Can be installed in rooms with high level humidity or lack of heat.

- The material is easy to cut, which facilitates the installation system.

- Extensive selection design solutions(The coating can not only be tinted, but also create mosaic patterns on its basis).

- There is no need to use thresholds in the areas of joints between the cork floor and the base covered with parquet or tiles.

Adhesive Disadvantages:

- Installation requires careful preparation of the base. Any differences in the surface will be evident after laying the coating.

- Requires the purchase of a varnish composition and glue.

- High-quality installation of the coating can only be done by specialists.

Note! The price of castle floors made of cork is much higher than glued ones. However, the installation of the latter requires the participation of specialists and the purchase of additional materials, due to which the total cost of the coating increases significantly.

The lock plug consists of:

- pressed agglomerate;

- fiberboard HDF or MDF, complete with mounting spikes and grooves;

- protective layer of agglomerate;

- veneer finish;

- protective layer of vinyl film or lacquer coating.

Advantages of castle floors:

- There is no need to cut the material. Installation does not require varnish and glue.

- It is not necessary to carefully level the base. A height difference of 2 mm per 2 m of the surface is allowed.

- A simple installation system allows you to lay the cork yourself without the help of specialists.

- It is possible to dismantle and reuse the material in another room.

The lock plates are not afraid of high humidity, but on condition that this indicator, like the temperature, is constant. The coating can withstand contact with water for no more than 24 hours. After that, it is necessary to dismantle the floors and dry its elements.

Choosing cork floors: owner reviews, pros and cons

When choosing a finish for floors, you should pay attention to the quality of the cork agglomerate. Some manufacturers, in order to reduce production costs, add cheap impurities to this layer, such as shavings. As a result, the material is hard, while it wears out faster. For this reason, it is worth giving preference to clean products, even if it is a compressed cork and its cost will be high.

Adhesive floors have their drawbacks. Even products from quality manufacturers can have small defects. Most often there are errors in size, which is why the slats have different size. As a rule, they are small and are 1 mm in length or width. This indicator is considered normal, because due to the elasticity of the material, this disadvantage is compensated during installation: the panels are compressed and the joints are tight. Sometimes there are slats with different thickness. This defect brings much more problems.

Helpful advice! If there are strips with different thicknesses in the batch, the material will have to be re-sorted. It is better to lay thin elements in those places where the transition will not be so noticeable. Thick ones can be corrected by removing excess thickness along the edges with sandpaper.

Since cork is a natural material, often on the surface there are such defects as depressions, an ugly color transition, as well as manufacturing defects (peeling of the veneer or its partial absence). Before proceeding with the installation, you should carefully examine the material, glue the peeled off places, and place the defective strips where they will not be so noticeable. Castle floors in this regard are more profitable, because the protective coating hides all the flaws.

Considerable importance is given to consumer reviews when choosing a cork flooring for floors. The opinion of buyers who have already tried this type of finish can be informative and decisive.

Strengths and weaknesses of cork floors: customer reviews

Cork flooring is not as popular as other finishes that are already well known to buyers. Those consumers who nevertheless ventured to purchase this material share their feedback on the cork laminate on the forums.

“At first we considered laminate flooring, but found it too noisy and slippery. We have a dog in our apartment. I don't want to listen to the constant clatter of claws. Parquet turned out to be unaffordable for us. Therefore, we decided to take a closer look at the cork coating. The material, of course, cost more laminate flooring, but its high price was outweighed by its many benefits. The coating turned out to be soft and quiet, and most importantly, warm. The cork was laid on the floor on their own, without calling the master to the house. I bribed the naturalness and environmental friendliness of this material. I don't regret my purchase at all and would recommend it to everyone. You won't find a more comfortable finish."

Svetlana Ezhova, Moscow

“I am ambivalent about cork floors. The material really has a lot useful properties. This is beauty, and naturalness, and the ability to keep warm. On the other hand, it cannot be called practical. Cork swells from water, so the seams between the plates may swell. I also cannot recommend this coating to those who have children in the house, because the surface of the cork is very sensitive to damage. The material requires careful handling. If you're willing to take proper care of it, cork won't disappoint."

Maria Korotaeva, St. Petersburg

What cork floors look like in the interior: photo

The use of this coating in the interior can be diverse. In the photo, cork floors look prestigious and original, especially in the living room, bedroom and office. It is allowed to use in the children's room, but subject to careful treatment. The coating can be made in natural colors (natural) or painted in any shade of the palette.

The most common natural colors:

- yellow;

- ocher;

- light brown;

- red-brown;

- mustard, etc.

Note! When choosing the color of the future coating, it is necessary to take into account the design and color of the furniture.

Can cork floors be used in the bathroom and kitchen

In any room where the microclimate involves a constant change in temperature, the cork will collapse and crumble. These rooms include not only the kitchen, but also the bathroom, which is also characterized by a high level of humidity. Temperature changes provoke the appearance of cracks in the coating. As a result, water begins to seep into the cork, causing the coating to peel off. It is also not recommended to use cork on the balcony and in the hallway.

Problem areas are usually hidden from view:

- under the bath;

- behind the plinth;

- under the sink;

- under the washing machine;

- for outdoor furniture.

It is in these zones that water vapor settles and condenses, destroying the coating. As an alternative, you can use a quality waterproof varnish to protect cork floors in the kitchen or bathroom. However, it does not prevent the appearance of mucous blisters. Under the influence of humidity, they appear under top layer coatings and spoil its appearance. In addition, the cork does not have antiseptic properties, so a microbiological environment can form under it.

Experts do not recommend using cork in the bathroom. With regard to the microclimate, the kitchen has more benign conditions, although even there the floor will be subjected to serious tests - constant pollution, spilled liquid (juices, coffee, tea), etc.

How to install cork floor tiles

Cork sensitively reacts to the level of moisture, shrinking and expanding depending on the conditions of the room. Therefore, before starting work, it is advisable to hold the packaging with the material for several days in the room where it will be laid. During this time, the humidity level stabilizes. As a substrate under the coating, you can use a technical roll cork. Optimal Thickness this material 2-3 mm. 1.5 cm should be retreated from the wall. The technical cork is placed on a waterproof film on top concrete screed.

Installation of the first row starts from the wall, which is located opposite front door, with an indent of 5 mm. If the material needs to be cut, the cut is made on the side where the comb is located. The groove cannot be touched. For cutting cork, it is advisable to use circular saw or electric jigsaw. It is better to refuse a hand tool, otherwise the cork will crumble. The set of the second row is carried out with an offset of half a tile. To adjust the elements, use a wedge (cork) and a rubber mallet.

Important! Be sure to leave a gap of 1-2 cm from the wall. Like any natural material, cork undergoes deformation changes, so you need to leave a small space for expansion.

After that, the coating is treated with several layers of varnish. The composition can be matte or glossy. The joint area near the wall is masked with wooden skirting boards.

How to properly install cork adhesive floors

Before work, the material must be sorted, selecting thinner elements. Thick strips must be sanded with sandpaper. The coating is laid on the base in the form of a concrete screed. It is allowed to mount the plug on old linoleum, but provided that its surface does not have swelling and damage. The main thing is that the surface is flat, smooth, free of dirt and debris. To level the base, you can use moisture-resistant plywood or fiberboard.

If there are small differences on the surface, it is advisable to apply a primer coat. It will not only eliminate minor irregularities, but also increase the adhesion of materials. The recommended level of humidity in the room is 65%, and the temperature is at least 18°C.

In this case, installation work should begin from the middle of the room. To simplify the process of laying the coating, it is desirable to apply markings to the surface of the base. This is for a cord. According to the instructions, the adhesive composition is prepared. It is applied to the surface of the boards with a roller. After that, the element is tightly pressed against the base, previously lubricated with glue. To apply the composition, you need to use a spatula with fine teeth.

Excess adhesive must be removed immediately. There are special substances intended for these purposes - solvents. You need to act very quickly. Prolonged contact of the solvent with the coating is not allowed. To more tightly press the tile to the floor, its surface must be rolled with a heavy roller (metal).

After all installation work is completed, the room must be ventilated. It takes at least 36 hours to dry the coating. Then the surface of the cork is thoroughly cleaned of debris and varnished in 3 layers. After 5-7 days, the floors can be exploited.

The benefits of cork finishing material obvious. At proper care the coating will retain its attractiveness for a long time. A wide range of colors and the possibility of applying prints allow you to create unique design premises. And subject to all the requirements of the technology, cork floors can be laid on their own and save a lot of money on this. Installation of the adhesive coating is more complicated in execution. But this type of flooring is perfectly combined with parquet and laminate.

Cork is a lightweight material known to many as necessary for corking expensive glass bottles of alcohol or making shoes. However, there is another wide scope of cork - construction, or rather, decoration. Cork flooring is a relatively new flooring option. decorative finishes premises, and this option raises many questions. In particular, it is believed that cork flooring is expensive, impractical and short-lived.

Today we will talk about the features, advantages and disadvantages of cork flooring, compare this unusual, if not exotic, building material with more familiar ones, for example, laminate or linoleum, and discuss the process of finishing the floor with cork sheets.

Cork is actually a tree bark removed from oak, which bears a similar name - cork. Oak groves grow in the lands of the Mediterranean. In Portugal and Spain, multi-hectare plantations of this valuable oak are specially cultivated, and these states have long been recognized as world centers for the processing of cork raw materials, the manufacture of finishing materials and related products from it. Note that oak plantations are also grown in Chinese territories, but cork oak needs a climate not only warm, but also with a certain level of humidity, and for this reason, Chinese cork is inferior to Portuguese and Spanish in quality.

When extracting cork, the tree is not cut down - the bark is simply removed from the trunks, leaving the oaks to grow further. From a tree that lives for more than one hundred and fifty years, the bark is removed regularly, every ten to twelve seasons. Therefore, the production of cork material does not harm nature, it is ecological and humane in relation to trees.

To create cork-bark panels, the raw materials are crushed into small pieces, poured into special molds and pressed in an oven under enormous air pressure and low temperature. Suberin is obtained there - a unique, lightest material, which is a mixture of cork crumble and air bubbles. Suberin plates are glued in two layers, using natural resin for this, and they turn into monolithic durable tiles.

What types of floor plugs are there?

The cork industry supplies cork to the construction markets different types. Suitable for floor use include:

- Whole type veneers. The most expensive cork material, consisting of a single, solid piece of oak bark. Tiles are most often made from veneer different sizes, thickness and color shades.

- Agglomerates. Sheets made from crushed cork bark, which is glued into sheets or multi-meter rolls using tree resin. Such a cork on the Russian market is the most budgetary, practical and common in hardware stores.

- A combination of agglomerate and veneer. Small and large cork chips in combination with veneer are glued together under pressure, pressing into sheets or boards. Combined cork is made from veneers that are not suitable for clean panels in terms of size or quality, supplemented with crushed bark.

If we talk about a combined floor cloth made of cork or agglomerate, then a front layer is usually applied to the front side of the finishing building material. It protects the floor from premature wear, and at the same time gives it a decorative and aesthetic effect. The front layers of the cork floor are divided into four varieties:

- Oak veneer protected with vinyl. Agglomerate top cover can be covered thin layer natural oak veneer, and then covered with a vinyl film that does not distort the natural pattern of the bark, but protects the cork from sunlight, scratches or moisture.

- Veneer from other wood species in combination with vinyl. The front layer looks and is made exactly the same as described in the previous paragraph, but it is no longer oak veneer that is used, but the bark of exotic or expensive wood species.

- Lacquer veneer. About half a centimeter of veneer is glued onto the pressed cork base, which is then varnished in two or three layers to make the coating more wear-resistant, as well as a pleasant shine and decorative effect.

- Thin veneer. Cork chips are simply “covered” with a beautiful veneer to hide the chaotic pattern of pressed bark.

Types of cork floor

The type of cork floor is selected depending on the purpose of finishing, as well as the available time and financial resources. On modern construction market There are three options for cork flooring.

Table 1. Three types of coverage

| View | Description |

|---|---|

| Adhesive | Cork adhesives are produced in the form of tiles of different sizes and thicknesses or rolls. Such tiles have a two-layer structure, where the bottom is pressed cork wood chips, and the top is decorative oak veneer, which is highly visually attractive. The adhesive floor is well tolerated by moisture, temperature changes, so it can be used in the area of the balcony, corridor, in the kitchen. However, the adhesive plug requires a perfectly even coating, so preparation before finishing is extremely important. For the installation of cork slabs, universal adhesives are used. |

| Castle | Lock-type cork floors are analogues of laminate. Such a coating is produced in the format of boards with fastening locks on the sides. The installation of the locking cork floor is carried out without an adhesive component or other fixing means, all that is needed is a substrate, as for a laminate. Coatings of this type consist of several layers, as a rule, the lowest, invisible layer is pressed natural oak bark chips, in the middle is MDF board, which gives strength, on top is a decorative layer of cork veneer or chips. |

| Technical | Technical coatings are made from the remnants of cork, so to speak, the surplus of production. Such a floor is not used for finishing, as it does not represent aesthetic value. Technical cork is produced in rolls or granules, and it is used to level defects in the base, or to insulate and level floors before laying tiles, laminate, parquet, linoleum. |

Cork as a floor covering: pros and cons

Like any construction material, a coating made from cork oak bark has disadvantages and advantages. Below we will talk about the pros and cons of cork so that you can evaluate this coverage in terms of your own tasks and goals.

Cork Benefits

Firstly, adhesive and locking coatings are environmentally friendly and natural materials that are not harmful to human health. Cork floor can be put even in the room small child or a family member suffering from asthma or allergies. It should be noted that not only the production of cork panels is environmentally friendly, but also the method of extracting cork - oaks do not suffer in this case, since the trees are not cut down, but simply “undressed”, removing the ripened bark.

In addition, the cork coating has an antistatic effect, that is, it prevents the accumulation of dust, mold spores and fungi do not start in the cork, and when heated, the material does not emit toxic harmful substances into the air and does not emit odor. Also, the cork is an excellent insulator - it has the effect of noise reduction, it keeps the heat in the room well. It is pleasant to walk barefoot on the cork floor, while the sound of footsteps will be muffled, and if any object falls on the surface lined with cork bark, then there will never be a sharp and unpleasant roar, never, only a thud

Any type of natural cork flooring is slightly springy underfoot, which is useful for children who are just starting to learn to walk, as well as those who suffer from ailments of the musculoskeletal or articular apparatus. Doctors admit that regular walking in a traffic jam reduces the load on the joints and bones, and forms the correct position of the feet. Another advantage of cork is that it does not slip, so a floor covered with this material will be a great solution in a house where there are children or the elderly.

The following group of advantages of cork coating can be classified as purely practical:

- Ease and efficiency of installation. Adhesive coating they simply press it to the floor surface, having previously lubricated it with an adhesive composition, the lock panels are laid like a laminate - a groove into a groove. Special knowledge and skills, as well as expensive tools for laying cork cloth on the floor are not required.

- Practicality and unpretentiousness. Caring for a cork floor is simple - it is recommended to wash it with a damp (not wet) cloth, vacuum or brush, sweep.

- Durability. If you do not spill solvents on the cork sheet and do not use abrasive cleaners, the coating will last at least ten years.

- The absence of gaps, the ability to abandon thresholds and skirting boards. The cork floor can be monolithic, as the plates are easily mounted without gaps. Thus, the cork floor perfectly connects with other coatings, for example, tiles (you can immediately lay them close), and if desired, there is also no indentation from the wall, which makes it possible to refuse the use of a skirting board.

A big plus of cork flooring is its versatility. You can use the cork both in the apartment and in country houses or at the cottage. Cork can be installed anywhere, the material is suitable for the kitchen or wet area of the bathroom, for the balcony or corridor, for the living room and any other living area. Cork itself has low moisture resistance, but if it is impregnated with a wax-based product, it will last for many years and in conditions of high humidity.

Disadvantages of Cork

The advantages listed above are significant, but cork floors are not without drawbacks. The first can be attributed to the high cost, and the adhesive floor will come out almost twice as expensive as the castle floor. The second drawback is the vulnerability to heavy objects, which include furniture. On the cork, the prints of the legs of cabinets and sofas will be perfectly preserved, and special gaskets will only slightly smooth out the traces.

If we talk about adhesive floors, then only the installation process will be easy, but it is extremely difficult to dismantle the panels, since a strong adhesive composition is used to fix them. Another disadvantage of the adhesive cork floor is the impossibility of using it immediately after laying, since the panels are impregnated with a special varnish, and it is necessary to wait for it to dry.

Which floor is better: adhesive or castle?

When choosing a cork flooring, each person faces a choice: to purchase adhesive panels or the so-called cork laminate, that is, lock panels. If we talk from the point of view of ease of installation, especially if the installation is carried out by a non-specialist, then the castle coating will be more advantageous. This tube is produced different forms, but they all have grooves on the sides, like a laminate. Accordingly, such a floor is mounted very simply - the boards or panels are joined together.

The castle floor has only two tangible advantages - ease of installation and, accordingly, dismantling, if necessary. There are more disadvantages: under the lock plug, it is necessary to lay a foam pad, and along the perimeter of the walls, the coating must be covered with skirting boards. Besides, a large number of joints imposes restrictions on the operation of the floor, in particular, on wet cleaning. The joints of the panels will absorb water and swell, so the locking coating must be coated with a special wax, and the seams should be treated with a hydrophobic sealant.

In addition, like a laminate, the lock plug must be selected according to the drawing, and in order for the final result to be aesthetic, the intended joints must be selected in advance. Accordingly, boards or panels will have to be sawn, picking up the length and ornament.

Adhesive cork coating has another drawback - you need to have experience for its installation. To make the floor durable and beautiful, it is necessary not only to correctly apply the adhesive composition to the base and the cork itself, but also to adjust the cork panels to each other so that they seem to be a single whole, without having the slightest gap.

The base on which the adhesive floor will be laid requires special attention. The bases must be perfectly flat, not have bumps, drops or protrusions, and before installation, the floor is washed several times to remove all debris. Restrictions also arise after laying such panels - since the adhesive cork is varnished, you can not step on a fresh floor, put furniture or any other objects on it until the varnish layer dries. You will not be able to use the room for a day or even more.

There are also several advantages to the adhesive cork floor. The first, and most important, is high durability coating, its solidity and wear resistance. Also, the cork floor made of glued panels is absolutely natural, and fully conveys the beautiful pattern of the tree. The glue plug can be placed on the floor as a solid canvas, or you can combine two or more shades, lay out the panels with various ornaments.

Another important plus is the ability to adjust the adhesive plug to any room by cutting out the tiles of the desired size and shape, no joints will be visible. High-quality installation of a glued cork floor allows you to do without the use of skirting boards, thresholds and other elements that cover seams, joints and gaps. Simply put, the adhesive plug is applied to the floor like wallpaper.

The adhesive cork has a small thickness of about five to six millimeters, so it does not hide the volume of a small room, but at the same time fully shows its soundproofing and heat-saving qualities.

How to choose a good cork floor?

Choosing floor material from cork, you need to focus not only on its appearance: glue or lock, but also on the class of application. Like laminate, cork sheets are divided into three classes of wear resistance, and this is an important parameter that ensures the reliability and aesthetics of the future floor.

So, the cork presented in Russian building stores is of the following classes:

- 33 - recommended for laying in residential premises, as well as commercial rooms with medium foot traffic (for example, in offices). Such floors for living rooms have an average guarantee of 25 years for the life of the cork, in commercial - 15 years.

- 32 - recommended for apartments or houses with laying in rooms with constant active movement (corridors, living rooms, kitchen area), as well as for offices or other commercial premises with low foot traffic. Warranty for laying in residential rooms - 15 years, commercial - 5 years.

- 31 - the cork is intended only for living rooms where traffic activity is low (bedroom, children's room for a small child). The guarantee for the coating is at least 10 years.

In addition to the class, you should pay attention to the brand manufacturer. It is good if the cork cloth is produced by a Portuguese or Spanish company. On the this moment market leaders are such brands as Wicanders, Corkstyle, Allied Cork. Average price per square meter cork flooring from these manufacturers varies between 1,600-2,700 rubles, respectively, cheaper options belong to class 31, those that are more expensive - to 32 and 33 classes.

How to lay a cork on the floor: instructions

Regardless of what type of cork coating will be used, you must first prepare the basis for it. There should be no serious irregularities or drops on the base (if the locking material is chosen), or an ideally smooth screed or leveling the floor with plywood boards (under the glue plug) should be used. After the base is ready, you can proceed with the installation.

Laying down the adhesive

Of course, by the time work begins, the cork floor itself should already be in the room, as well as a special varnish to cover the cork after installation. To independently lay an adhesive-type cork coating on the floor, you will need the following tools and fixtures:

- A thin, coarse-haired paint brush for applying glue.

- Rubber mallet.

- Gloves to protect hands from adhesive mass.

- Construction knife for cutting tiles.

- Roulette.

- Roller with a long handle to varnish the floor.

Step one

Laying the floor is always started five or six rows from the wall, the width of the row is always a multiple of the width of the cork tile itself. The material is laid with joints lengthwise to the light. Depending on the shape and size of the adhesive plug tiles, the pattern of the future floor must be selected. As a standard, the cork is laid in a run, that is, its transverse joints never coincide, and the pattern according to which the tiles are displaced is not guessed. You can lay cork tiles on the floor without glue, estimating how many of them will fit in a row, and also arranging them according to the shade or pattern. If the cork comes in a roll, this step can be skipped.

step two

Using a paint brush, glue is applied to the floor and tiles. You can immediately spread a whole strip on the base, and also apply glue to four or five cork tiles at once, so that they can be laid on the floor one by one without wasting time. The cork in the roll is glued in the manner of wallpaper - that is, they smear both the base and the cork strip itself from beginning to end. Next, the adhesive mass should dry, follow the instructions indicated on the package with glue. It usually takes fifteen minutes to half an hour to dry.

Step Three

Let's start laying tiles. Two rows can be glued at the same time. The first tile is laid, according to the drawing, then next to it, on the side, the second tile is tightly glued, with a two-thirds offset. So there are two rows that continue to the wall. Most likely, the last cork tile in the row that is in contact with the wall will have to be cut. This must be done precisely in the process of laying the cork on the glue, and not in advance, in order to leave a minimum gap. Right size measured with a tape measure, and then cut off with a sharp construction knife- it perfectly cuts a thin glue plug. Thus, the entire floor is laid out in the direction from the center of the room to the walls.

Roll cork is easier to glue - the required length of the web is laid out on the floor, cut off from the roll, like wallpaper.

Table 2. What adhesive can be used?

| Name | Features, description | approximate cost |

|---|---|---|

| Quelyd Kork, France | One-component self-drying compound. Has an environmental safety class, can be used for heated floors. Setting time is about 25 minutes. | About 1,300 rubles for a package of 3 kilograms |

| Moment "Probka", Russia | Waterproof and resistant to negative temperatures, quickly and reliably glues cork to any surface (wood, concrete, iron, rubber, and so on). Setting time is about 20 minutes. | About 550 rubles for a package of 1 liter |

| Decol Vern, Portugal | Contact (instantly seizing) adhesive composition, reliably and monolithically connecting the cork of any thickness with the base. The manufacturer does not recommend working with this adhesive without professional skills. Setting time - 15 minutes. | About 2,450 rubles for a package of 5 liters |

| Mapei Ultrabond Eco Contact, Italy | It is odorless, does not flow (thick paste type), suitable for laying cork sheets in areas with high pedestrian activity. Has an environmental certificate. Setting time - 45 minutes. | About 2,300 rubles for a package of 2.5 kilograms |

| Cipade Reviprene, Portugal | Contact, very strong adhesive composition, designed specifically for working with cork. Contains rubber components, intended for professional use. Setting time - 15 minutes. | About 2,300 rubles for a package of 5 liters |

Step Four

When the floor is completely laid, it must be varnished. A special varnish, which can be purchased in the same department as cork, is applied with a long-handled nap roller. You need to start applying the varnish layer from the far wall to the exit, so that in the process you back towards the doors, and not vice versa. The varnish does not need to be spared - the mass should fill in all the joints and possible irregularities in the canvas.

Important point! Before starting varnishing, you need to mix the varnish thoroughly, and then repeat the procedure every ten minutes so that the coating is uniform. Joints at the wall must be passed paint brush, because it is impossible to do it evenly and qualitatively with a roller.

Cork Lacquer is a versatile coating that gives not only a visual effect, but also protects the flooring material. The floor must be varnished immediately after laying, so you need to purchase the product in advance.

Table 3. What varnish can be used?

| Name | Features, description | approximate cost |

|---|---|---|

| Lobadur 2K Supra Cork, Germany | A low odor transparent matt lacquer suitable for use in heavily used areas. Moisture resistant and frost resistant. Consumption - 100 grams per square meter. | About 2,200 rubles per pack of 1 liter |

| BONA Traffic, Sweden | Two component lacquer water based, especially resistant to abrasion, perfectly adheres to the cork without chipping during operation. Consumption - 120 grams per square meter. | About 12,000 rubles for a package of 5 liters |

| BERGER Aqua-Seal 2K-PU, Germany | One of the most durable and strong varnishes on the market. It is environmentally friendly, dries quickly, does not have a strong pronounced odor, and has passed fire resistance tests. Consumption - 100 grams per square meter. | About 4,700 rubles for a package of 1.6 liters |

| LOBADUR WS EasyFinish, Germany | Water-based universal one-component varnish, additionally emphasizing the pattern of cork bark. Odorless, wear resistant. Consumption - 100 grams per square meter. | About 15,000 rubles for a package of 10 liters |

Video - Laying a cork floor on glue

We lay the castle cover

Before laying such a cork, the entire floor must be covered with a special foam substrate, exactly the same as that placed under the laminate. In addition to the cork itself and the substrate, you will need:

- Roulettes or ruler.

- An electric or hand file to saw off excess blade.

- Gloves protecting hands.

Step one

Installation of the lock plug starts from the wall. Along it, the first row of tiles or boards is laid, which are attached to each other by connecting the end grooves. If the floor is mounted in a room with high humidity, the grooves are additionally coated with a special joint sealant before connecting.

step two

Next, the second row is laid - the cork is connected to the first row by side grooves. Thus, the entire canvas stands up, right up to the next wall. Pay attention to the details that will require trimming - it is better to place them in a less visible part of the room or where the furniture will stand.

Step Three

After the cork is laid on the floor, you need to screw the skirting boards. Accordingly, there may be a gap of up to one centimeter between the wall and the extreme tiles - this joint will be hidden by the skirting board.

Video - Installation of a lock-type plug

How to care for a cork floor?

Cork flooring is beautiful and practical, especially in terms of maintenance. But, there are also rules and recommendations regarding the operation and maintenance of such a coating clean. First, you need to monitor the humidity in the room so that the floor does not dry out. As we mentioned, cork oaks grow in climates with high humidity, so in rooms where this figure is below 50%, you need to use special air washers or humidifiers.

Caring for a cork floor is simple: varnished or wax-impregnated material can be wiped damp, but not wet rag, vacuum, use household chemicals for wooden bases(without abrasive and solvent). However, if liquid is spilled on the floor from the cork, you need to immediately wipe the puddle so that the area where the moisture gets in does not swell. It is forbidden to use hard, iron sponges or aggressive brushes to care for the cork; it is not necessary to clean such a surface with scrapers.

Another important point in cork care is its periodic renewal. Since the cork floor begins to lose its aesthetics over the years, and the varnish fades, you need to restore it. With the help of a grinder or sandpaper, the remnants of the old lacquer coating are removed from the floor, the dust is carefully collected with a broom and a vacuum cleaner, the cork is wiped clean and then varnished again. After a day, the floor will dry, and will sparkle again with its unique texture and pattern of natural oak bark!

Summarizing

Cork flooring, as it becomes clear from the above, is a great option for any living space, which has a lot of advantages. If you are one of those people who value the naturalness of materials, ease of installation and ease of maintenance, then we recommend that you consider cork oak bark!

Why is cork flooring so popular today and is it considered the best finishing material? Everything is very simple!! Such a coating is of very high quality, the coating is made from real tree bark, but they do not grow here - they can only be found in warm countries. If we look deeper, the structure of this crust is very unusual, since it consists mainly of oxygen pores. Due to the fact that oxygen is literally in a clogged state, cork flooring has excellent elasticity and resilience. The material from which the adhesive cork floor is subsequently made is very light but at the same time quite strong.

This feature of the material attracts a huge number of buyers to itself. In addition, cork adhesive flooring has high thermal insulation properties and high-quality sound insulation. All of the above qualities make it possible to use cork as a finishing material for a home or other premises. Some may say that they will not buy this material just because of the name: how can a tree bark floor be strong? Let's try to figure it out!

How to choose cork flooring

Before the direct acquisition of this material, it is necessary to determine some facts that are of great importance during the selection and purchase of this product.

This type of coating is perfect for the kitchen, as it is moisture resistant and resistant to various thermal changes. It is worth noting that the cork material does not rot, such a wonderful property gives it millions of nitrogen bubbles, and they prevent this process. Therefore, you can wash cork floors at least every day, they are not in danger.

In hallways and corridors, this type of material should not be used, this is explained very simply - the corridor and hallway usually bear high mechanical loads, in these places there is always dirt and dust, which will greatly worsen this type of flooring. In order to make it easier to understand the variety of cork flooring, we suggest that you carefully study all the options for this material and look at the photos available on our website.

There are two main types of cork flooring - adhesive and locking. The castle view among builders is called floating, because it is not fixed like other types to the floor surface. This type of floor is very similar to laminate in terms of its installation and connection principle. Therefore, you can often hear it called cork laminate. With regards to the adhesive type of coating, here you can understand from the name itself how it is connected to the floor.

These two types of cork floor differ not only in the way of installation, they also differ in the layers from which they are assembled. Also, the dimensions of the material can also be different, for example, the thickness of the locking panel is 10mm, the width is 300mm, and the length is 900mm. The bottom layer of this type of panel is made of crushed cork in the form of a panel. Next comes a layer of MDF or HDF, this material is made from wood fibers by pressing at a very high temperature. The third layer of the locking panel is made of 3mm thick cork. Most often, the manufacturer applies vinyl, acrylic or ceramic varnish on top of this material. But on sale you can find this material without coating, it will also need to be coated with some composition, but after direct installation.

Adhesive panels, called cork parquet, are glued to the floor, they are produced in various sizes, but most often they can be found in lengths of 600 or 300mm, and the thickness of cork flooring is 4-6mm. Adhesive floor may have a factory lacquered in several layers. Of course, you can buy cork flooring with a single layer coating, but then after installing it you will have to paint it.

Coating characteristics

AT winter period time on such a floor you can safely lie, sit and even walk barefoot. This can be done due to the fact that cork has such a wonderful property as heat retention. Therefore, people with children do not have to worry that the child will get sick while sitting on the floor.

Cork perfectly keeps noise, such a coating is perfect for families who like to invite many guests in the evening, you will not disturb your neighbors with your noisy feasts, as the floor perfectly absorbs noise.

It is very pleasant to walk on such a floor, as it springs during walking, and it will not be so painful for small children to fall. Also, your dishes will remain safe and sound, as if they fall on such a coating, they will not break.

Cork itself is hypoallergenic and safe for human health. The coating does not electrify at all and does not collect dust. Among other things, it is dirt repellent.

pros

- Moisture resistance. Adhesive cork floors have very good moisture resistance. It will never be harmed by tea, water or coffee spilled on it. With castle type But things are a little different, if you spill water on it and leave it, then after a while you will find swollen cork slabs. For this reason, the castle floor cannot be laid in the bathroom or kitchen.

- Resistance to deformation. On such material, there are almost never any traces of furniture. In some cases, when the furniture support is very small and sharp, when the furniture is very heavy, it can leave marks on the floor. But more often than not, these traces disappear over time, the thing is that the cork floor tends to return to its original form.

- Smoothness. Depending on the finish of your pod, the smoothness will vary. For example, if the floor is covered with acrylic varnish, it will be very slippery and it is very easy to fall on it. Ceramic lacquer, on the contrary, is very durable and a little rough, such a coating is much safer, it is recommended to use it for those people who have children or elderly people live.

Minuses

- Not durable. The service life is only five years, of course, it all depends on the operation, with careful use, this flooring can last up to 20 years.

- High price. The cost per square meter is 1200/2600 rubles. behind castle view and 800 rubles. for glue.

Types of cork panel

- Technical view of the tile.

- Cork floor.

- Adhesive cork coating.

- Castle cork floor.

How is cork flooring installed?

Laying this material on the floor requires care, scrupulousness and responsibility. To work, you will need the following tools:

- Putty knife.

- Cutter.

- roller.

- Pencil, napkins, ruler.

- .Roulette.

- Grinding.

- Rubber mallet.

The diagram clearly shows how the cork floor should be installed.

Adhesive floor

Before the direct laying of the adhesive floor, it is first necessary to make a high-quality marking of the room where the floor will be laid. The material must be laid from the very center of the room and already from this point it is necessary to designate parallel lines to the walls. First you need to try on the plates without applying to them adhesive composition, this must be done, because the special adhesive for cork floor sets very quickly. If for some reason your tile is uneven with a slight misalignment, you will need to level the base.

Apply a small amount of contact adhesive to work surface floor and wait thirty minutes. After this period of time, the adhesive must be applied to the bottom of the cork tile and immediately laid end-to-end, without any gaps. Be sure to firmly press the tile after gluing with your hands to the base and hold for a while until the glue sets. Then take a rubber mallet and completely tap the cork floor with it, or if you have a special roller, then roll it over the entire surface of the floor covering.

If glue has come out on the cork tile in some places, then it will immediately need to be removed. If you have good ventilation in the room, then the glue will dry in two days, which is quite optimal time. Usually, the tiles never fit completely against the walls, so it will need to be cut, be prepared for this. After installation, it is necessary to make high-quality grinding of the floor, and then degrease it. After that, the floor covering can be treated with varnish or regular wax, according to your desire. The number of layers primarily depends on the material itself, if you bought a material without a factory coating, then about three layers will be required, if you buy a painted cork, then two layers will be enough.

castle floor

Cork floors are always mounted in a “floating” way with the help of special locks (glue is not used here). This type of flooring is often sold paired with an underlayment. Cork slabs are carefully installed on the floor by closing the lock, this similar work like installing laminate flooring.

It is necessary to lay the plates carefully, namely from the edge of the wall itself to the wall on the opposite side. At the same time, the slabs must be joined using the “brickwork” method; joints of four tiles must not be allowed at the same time.

Make sure that the small side of your plate is parallel to the wall with the doorway - with such actions, the room will turn out to be visually stretched.

The cork floor must be varnished to protect it from water penetration. You can also use special gels - sealants for putty joints between tiles. Before painting the floor with a roller, you need to apply varnish with a brush along the very edges, near the wall. The cork floor is not at all unpretentious in care, it can be easily washed with a wet sponge.

Pay special attention!

The last row of this material must certainly have a width of at least five centimeters. If it comes out much smaller, you need to cut the set width from the lamella of the very first row. The cut must be made along the long part of each floor element.

How to make a cork floor happy for as long as possible

To ensure that your furniture does not damage the coating, you need to rearrange it very carefully. You can also play it safe: stick felt on the furniture legs, so you will not scratch the coating. During any cleaning, the floor cloth should be wrung out with high quality, it is not necessary to use abrasive products during cleaning. Over time, the lacquer coating is erased, so once every 5 years it needs to be renewed.

As you can see for yourself, choosing a cork floor is very difficult. But it is justified by its quality, beauty, and ease of use. With such floor in your dwelling there will always be a cosiness, comfort and health. Well, information about some of the features of this material will help you not to make a mistake in your choice.

Video instruction

To consolidate the knowledge gained, let's watch a video report on the installation of adhesive-based cork flooring.

Yes, yes, we will talk about the very cork that clogs bottles with expensive wine. Cork is the bark of a cork oak that grows in the Western Mediterranean. It is the lightest of the natural hard surfaces. What makes cork even more attractive is its low sound and heat conductivity, as well as the fact that it does not absorb many liquids. Such unique material could not go unnoticed: it is used with might and main in rough and fine finishing.

From cork bark to flooring

Only two types of oak give real cork bark. The first "harvest" can be removed at 25-30 years of tree life. The bark is cut in a circle and carefully removed with the sharp end of the ax handle. This cork does not work: the first layer is too hard and falls apart into small pieces.

After that, the tree is left alone for 6–9 years and waiting for the next layer to grow, already suitable for use. By the way, properly executed cork removal does not cause any harm to the tree.

The removed cork is turned into floor (as well as wall and even ceiling) coverings in different ways. More precisely, the technology is the same, but the costs and quality of the source material are different. So, the cork coating can be of the following types:

- Solid cork veneer. The most expensive type of cork. Individual floorboards in one collection are selected by color.

- Agglomerate. This is a cork crumb, which is pressed at high temperature into a single coating. Most cheap option: any pieces are used, down to the smallest ones.

- Combination of agglomerate and large veneer. This is a compromise solution in which large pieces of veneer and small pieces coexist.

Agglomerate (cork from crumbs)  Agglomerate. Small and medium crumb

Agglomerate. Small and medium crumb  Agglomerate

Agglomerate

In terms of wear resistance and mechanical properties, these types of cork do not differ. The difference lies in appearance and the fact that for better gluing of crumbs, plasticizers are used, which call into question the environmental friendliness of such a cork. Therefore, keep in mind: most often, sellers praise the environmental friendliness and naturalness of cork, meaning veneer, but they sell agglomerate.

Types of cork coatings

Of those cork coverings that are laid on the floor, technical cork, adhesive coatings and floating floors stand out.

technical traffic jam available in rolls, plates and even granules. It is used as a substrate under the main floor (for example, laminate) for insulation and soundproofing. Cork crumb filling voids between walls and floors.

Adhesive cork covers released in the form of tiles. Their size is 300x300, 450x150, 600x300, 450x450 mm. Can be sold with or without a top coat. Thanks to the standard sizes of cork tiles different color you can post patterns and drawings. This type of cork is considered the most resistant to water and is used in wet areas.

floating cork floor(aka cork parquet) is a cork coating glued to MDF. It is produced in the form of panels measuring 900 × 185 mm and is assembled according to the same principle as the castle laminate. It is better not to fill such a floor with water: MDF can swell.

Veneer and agglomerate

Veneer and agglomerate  Cork floor in the kitchen

Cork floor in the kitchen  Cork tiles in the kitchen

Cork tiles in the kitchen

Advantages of cork

The advantages of cork are talked about a lot and convincingly. If we discard emotions, the following undeniable properties of it remain:

Cork provides very good heat and sound insulation. Such a floor will be warm, pleasant to the touch and slightly springy underfoot.

The cork is not afraid of water and does not rot, it is chemically inert.

Cork is not eaten by beetles, rodents and microorganisms.

Disadvantages of cork flooring

The first disadvantage of cork is its price. A meter and a floor will cost you 1000–1700 rubles. for parquet and from 400 to 1000 r. for a cork for glue. The price depends on the thickness of the cork layer and the type of coating (veneer, agglomerate).

Cork floor owners often complain about furniture marks. No matter what the sellers say, the trace of a cabinet or even a bedside table does not disappear completely, but reminds of itself with a dent.

The protective layer that the cork is covered with wears out over time. In places of heavy traffic (corridors, kitchen) a path will be trodden. This means that the cork floor will have to be updated (removed old varnish, recoat) or change.

What else to read

THE LAST NOTES

- Amber extraction method in Belarus

- “Soon products from amber will arrive on store shelves”: trial amber mining has begun in the Brest region

- How to open an IP in Belarus

- Is it necessary to pay contributions to the social security budget for an employee who is on unpaid leave?

- What to give a man after parting