DIY wooden rocking chairs. DIY chair: rocking chair, bag, hanging

- Manufacturing of parts

- Assembling a rocking chair

There is no person who has not dreamed of having a chair in which to swing on a quiet summer evening on a cozy veranda. Someone managed to make their dream come true by buying a house with a veranda and a rocking chair, while others only had enough money to buy a blanket for him. Don’t despair, a rocking chair is easy to make with your own hands. Its most complex element - the runners - can be made without the use of complicated operations. A piece of furniture that will fit even on a balcony will help you make your own drawings of a rocking chair, where all the dimensions of the blanks for its manufacture are indicated. When you have a rocking chair made by yourself, you shouldn’t throw away the drawings; your friends will probably need them too.

Selection of material and tools

The process of making a chair begins with the selection of material. You may have everything you need to create a rocking chair in your garage or closet. Otherwise you will have to go to the store. There you will buy:

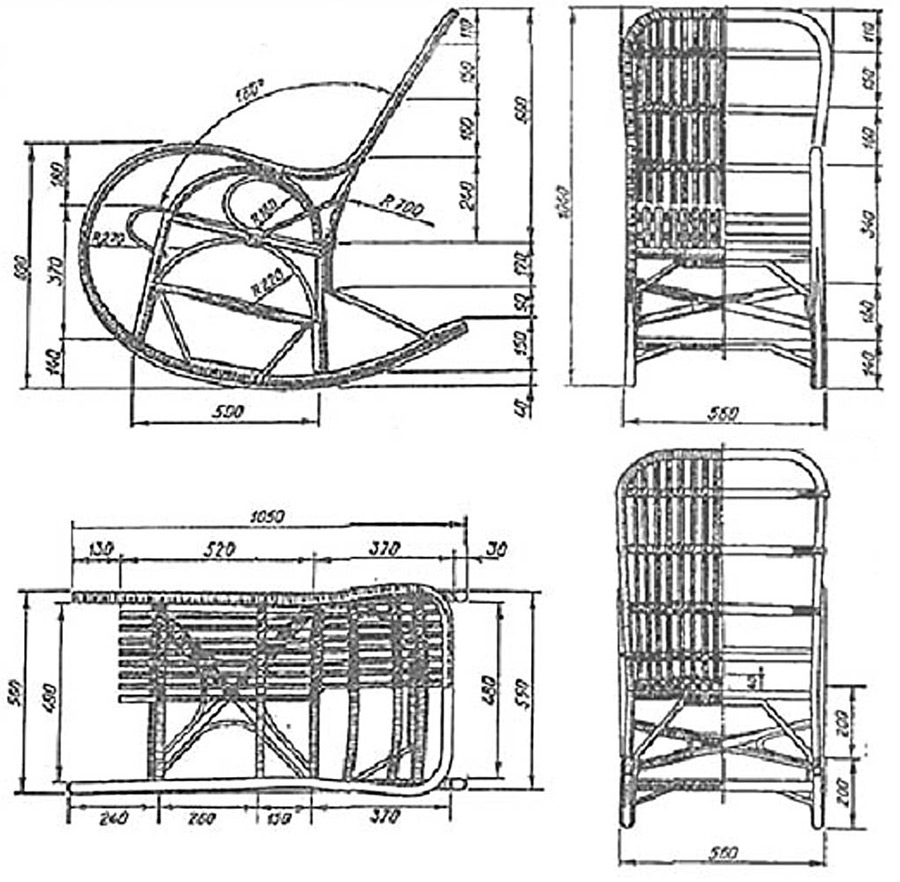

Figure 1. Drawing of a rocking chair.

- thick furniture polyurethane foam (foam rubber) for pillows;

- thick fabric for covering them;

- bars 20 x 20 mm or 20 mm FC plywood;

- 10mm plywood for the seat;

- board 200 x 20 mm for runners;

- wood glue;

- confirmations and screws;

- impregnation for wood and coating materials (stain, paint, varnish).

To do this, you will spend no more than 2 thousand rubles.

To avoid buying unnecessary materials, look at Figure No. 1, which shows a drawing of the chair. Using it you can determine the dimensions of all parts. Don’t be confused by the fact that the seat plane will be located only 20 cm from the runners. It serves only as a base for a thick polyurethane foam cushion. It is worth adding that both pillows will not be attached to the structure.

Prepare the following tools for work:

- jigsaw, hacksaw or circular saw;

- drill-driver;

- electric planer, planer, belt sander or sandpaper;

- brush;

- knife (for cutting polyurethane foam).

You will also need tailoring supplies, but for a man making covers is an impossible task. Therefore, if you are unable to do this work yourself, entrust it to more to an experienced master- to a woman.

Return to contents

Manufacturing of parts

Rocking chair assembly diagram: 1 - longitudinal frame element; 2 - transverse element of the frame, 3 - front leg, 4 - rear leg, 5 - support bars, 6 - cross member, 7, 8 - runner element, 9 - back support, 10 - backrest tilt lock, 11 - armrest stand, 12 - armrest, 13- back frame, A - frame assembly, B - installation of seat and runners, C - runner configuration.

When making a chair with your own hands, you can lengthen its runners and strengthen them with jumpers. The rocking chair, the drawing of which is shown here, is intended for tight spaces, but the shortened arcs will still prevent it from tipping over if you make the runners according to the recommended radius.

Start your work with them. Mark the board or prepare a template from paper and transfer it to the wood. Cut out both arcs. A pattern made according to the profile of a rocking chair will help to more accurately produce all its parts. Cut according to the specified dimensions and using the template. wooden blocks. If you decide to use plywood, cut strips of 20 x 20 mm from it and cut them into pieces of the required length. Cut out the base for the seat.

Sand all surfaces thoroughly with sandpaper. Try to ensure that there are no sharp edges left on the workpieces. The product will look more attractive if the bars of the armrests, the top crossbar of the backrest and the arcs at the ends are slightly rounded. After cleaning the faces and edges of all workpieces, saturate the wood with drying oil or other protective compounds. Their choice depends on the type finishing coating, which will be applied after assembling the rocking chair.

Alexey Shamborsky, 12/05/2016

In his country house I want to have comfortable comfortable furniture with non-standard design, in which you could thoroughly relax and unwind. DIY wooden rocking chair, made in your own way individual project, is perfect for these purposes. In this article we will look at a master class on its production with presented photo and video materials of each stage.

Preparatory design stage

Creating a rocking chair made of wood begins with the design part. To do this, you need to clearly imagine the final version of the product. We'll consider classic version making a wicker rocking chair, the model of which was invented a long time ago.

Before starting work, it is necessary to make a pattern of all parts of the future product. For this you can use a special computer program, which, based on the photo, can give the dimensions and configuration of all parts of the product. You can also make drawings with dimensions yourself on thick paper, from which you can cut out stencils for future pieces of furniture. To create the correct geometric shapes, you need to stock up on a set of different patterns and compasses.

Selecting materials for creating a rocking chair

When the design part is fully developed, we decide on the materials of the product. For a wooden rocking chair, it is advisable to choose plastic species that can be easily bent and processed. An excellent material for this is willow vine, which is lightweight, easily takes on given shapes and looks beautiful.

Another commonly used material for creating country furniture is rattan. The products are openwork, light and airy. Furniture made from rattan and wicker wins with its attractive appearance, but is inferior in strength and durability to products made from other types of wood.

We will consider the option of making a more substantial rocking chair from maple plywood. Maple has great strength and wear resistance, has a beautiful textured pattern, but is a harder and denser rock. Therefore, in order to create reliable furniture, you need to apply certain knowledge and skill.

Maple wood surfaces are more difficult to bend and shape various shapes, as in the case of using wicker and rattan, but at the same time the rock is quite plastic, does not crack or warp. Maple products are distinguished by their long service life and aesthetic appeal.

Making a chair

![]()

We will make our rocking chair with our own hands according to a classic antique design. The product will be installed on two curved runners and have a high back beautiful shape and openwork wicker elements made of reeds.

![]()

We begin the process by making the frame of the product. Using the prepared templates, we transfer the drawings of the frame parts to wood plywood and bars. We carefully cut out all the parts using a jigsaw and grinding machine and connect them to each other using screws. Much attention must be paid to the processing of wooden surfaces so that they are perfectly smooth and free of burrs. To do this, we finally clean all the parts with sandpaper.

The resulting finished product must be processed with reliable protective coating, which will make wooden surfaces more durable and resistant to moisture. To do this, you can use special paints, water-repellent varnishes, and antiseptic impregnations. Transparent varnishes will do wooden surface brighter and more saturated and will emphasize the beauty of the natural pattern of the rock.

This article presents full information on how to make a rocking chair with your own hands at home. Such a product can be easily moved around the house, taken outside to relax in the shade of trees on fresh air. Old classic design chairs go well with other wooden furniture and the general theme of a rustic country house.

Video of making a rocking chair with your own hands

Much has been written about the beneficial effects of relaxing in a rocking chair. It also helps to concentrate during intellectual work. Finally, it’s just convenient, after pumping, to take books from the rack behind your back or a cup of coffee from coffee table. The prices of ready-made rocking chairs, as it should be in a consumer society, react to such advantages in their own adequate way: a rocking chair for 5,000 rubles. it's still cheap. And people are artisans and also respond adequately in their own way: there are more and more people wanting to make a rocking chair with their own hands. However, the rocking chair differs from other pieces of furniture, firstly, in that the whole thing moves and swings. Secondly, so that it does not turn from a rocking chair into a kicker or tipper, the entire product with the person seated in it must have a precise balance, which must be maintained within acceptable limits for riders of different weights and builds. This publication is devoted to consideration of issues of how to achieve the required qualities of a rocking chair.

Types of rocking chairs

You need to comply with your own needs already at the stage of choosing a prototype. There are several types of rocking chairs, aimed at users with different habits and needs. The main types of rocking chairs are shown in the photo. Rocking chairs on simple radius runners (arches, rocker arms, skis) were the first to appear in everyday use. They are in use to this day, both in modern and classic appearance, pos. 1 and 2. Their main advantage is constructive and technological simplicity.

Radius runners provide smoothness and softness of rocking only with relatively small swings, and with strong swings they do not guarantee against tipping over. Therefore, rockers “on radii” are made with a low landing, ensuring a large excess of the center of the generating circle (CO) over the general center of gravity (CG); For more details on the kinematics of rocking chairs, see below. If a seat of normal height is required, then the runners are equipped with bumpers, pos. 3. The shocks of the bump stops on the floor are noticeably felt at the “fifth point”, and in any case you have to get out of the rocking chair on the radius runners, straining somewhat.

Note: Stability when swinging with a slightly larger amplitude at a normal landing height is provided by rockers on radius runners with a closing horizontal arc, see fig. on right. But, suddenly the limit is reached, the supporting surface instantly reduces to a point and a sharp push follows in the back.

Tipping is excluded in rocking chairs on runners of variable curvature, pos. 4. All of them are comfortable enough for riders of different body types. They themselves gently unseat the rider of a rocking chair of the Nirvana type who has stood up and leaned forward on runners of variable curvature, pos. 5 and 6. It is also possible, by changing the progression indicator in the law of change of the generating radius (also see about kinematics), to design them for any landing height, within acceptable limits.

Note: mother and baby are given complete rest with complete unity of souls in the rocking cradle. Reliable rockers with a cradle are made only on runners of variable curvature, see fig. on right. Otherwise, suddenly the little one will get worried and the mother will perk up, and we can tumble together. Which is simply dangerous for a baby.

Nirvana rocking chairs on elliptical runners, pos. 7, provide a gentle, truly blissful rocking, but do not prevent tipping over during strong swings, so they are equipped with bump stops; the front one is often combined with a footrest. Garden rocking chairs with ellipse awnings never tip over, pos. 8.

Nirvana rockers on springs, see fig. on the left, they swing as softly as on ellipses, because mechanical characteristics Progressive springs. But making a spring chair with your own hands is difficult: you need either high-quality boards of special types of wood (teak, boxwood, dogwood) or a rubberized strip of spring steel so that it does not scratch the floor. In addition, dirt gets packed into the gap between the spring and the runner and it can be very painful to pinch your finger. For the latter reasons, spring chairs are now very rare on sale.

Rocking chair 3 in 1

Finally, there are also multifunctional “3 in 1” rockers on runners with smooth bends, see fig. on right. When seated upright, this is a regular chair; by leaning back, it can be switched to rocking mode on radii, and by leaning back even more, it can be turned into a sun lounger. But the dimensions of the 3 in 1 rocking chair are too large for apartments below business class, and transitions from mode to mode are accompanied by rather sensitive shocks. In unsuccessful models, you either have to stand up or twitch, squirm and fidget like a puppet on strings. Therefore, 3 in 1 rocking chairs are a piece of furniture for everyone.

To start

Without any special pretensions, just to relax after work, a rocking chair on radius runners will help. Drawings of a simple sample, made, with the exception of the runners, only from straight parts, are given in Fig. This chair can be made for a dacha, veranda or garden in half a day, using only a jigsaw, a drill and a pair of wrenches (assembly is bolted). And having swayed to your heart's content, you might already think about home rocking chair for the more experienced; then you will need a more thorough tool and knowledge.

How does it swing?

Most home craftsmen make rocking chairs according to ready-made drawings, but prototypes often turn out to be developed and tailored to a specific person, and an exact replica is not so convenient. Therefore, before making a rocking chair, it is necessary to obtain at least initial information about its kinematics.

CG straight standing man normal build located on the border of the lumbar and sacrum with inside spinal column. In a sitting individual, it will blend somewhat forward and even less downward. In the chair-seat system, the overall CG shifts back almost to its original position and a little further down. The downward shift of the general CG for the design of a rocking chair is not particularly significant and we can assume that the projection of the general CG onto the supporting surface (floor) is approximately the same as that of a standing person. In the future, the resulting error can be easily compensated by final balancing of the chair, see below.

The vertical location of the central center relative to the central center has a much stronger effect on the stability and comfort of the rocking chair; the latter is also a determining factor when designing rocking chairs on runners with variable curvature. If the CG and CO coincide, this is an indifferent equilibrium: for any physically possible tilt of the chair, the projection of the CG on the floor falls on the point of contact of the runners O, pos. 1 and 1a in Fig. The chair does not rock, and if you lean back too much, you will instantly somersault with the risk of breaking your neck. Fortunately, an exact match between the CG and the CO is only theoretically possible.

If the CG is higher than the CO, then its projection, at any inclination, “runs” outward, backward or forward, from the point of contact. At the slightest tilt, a tilting moment Mo occurs (positions 2 and 2a), and the rocking chair turns out to be unstable. To avoid such a situation for a family rocking chair, it is designed and balanced for the tallest, heaviest and pot-bellied rider possible so that its CO is 450 mm or more higher than the CO. Then, when the chair is tilted, the point O will “run away” from the CG projection, the restoring moment Mv will constantly act (positions 3 and 3a) and the chair will not tip over when rocking within acceptable limits. For those who are smaller, the excess of the CO over the CG will be too large, and the swaying will be harsh, but this can be easily compensated for by pillows under the back and seat. In general, the lower the elevation of the CO above the CG, the softer and smoother the swaying, but the likelihood of capsizing, suddenly straightening up and standing up in a chair, is higher. Therefore, it is better for novice carpenters to set the CO exceeding within 600-700 mm.

Note: if it is impossible to determine the position of the CG of the largest of the riders (say, in his absence), the radius of the generating circle R is taken equal to the average height of the users minus 5 cm. Suddenly the rocking turns out to be harsh, this can be corrected by placing a permanent pillow on the seat.

There is no need to drag your own pillows with you into a chair on runners of variable curvature: it will itself rise to the position of greatest comfort. At the same time, the big guy will lean back more, and the slender one will sit straighter. When swinging backwards, the point O will run away from the CG projection the further, the greater the angle of inclination, and it will simply not be possible to swing until it capsizes. And if you “pump” forward, which is actually difficult, the chair will smoothly drop the hyperactive person onto the floor: where should you rest? Go do something.

To construct a profile of runners of variable curvature, the radius of the generatrix of the circle (it is determined as in the previous case) will have to, firstly, be rotated several times by a fixed angle α; usually take α = 10 degrees. Secondly, to build the rear branch of the runner, R is increased at each turn according to the law of geometric progression with the index k = 1.02-1.03. That is, it will be (see position 4 in Fig.) R1 = kR; R2 = kR1; R3 = kR2; R4 = kR3, etc., if required. Actually, R changes according to some trigonometric function, but for furniture accuracy and the size of the rocking chair, it is more convenient to replace it with a progression, so it’s easier to calculate.

The construction of the anterior branch is carried out at a constant R, but with each rotation of the generatrix of the circle, the CO is raised vertically (ibid., in position 4 of the figure). The initial elevation Δh1 is taken equal to 2-3% R, i.e. (0.02-0.03)R, and the subsequent ones also follow a geometric progression with the same indicator as for the posterior branch. Δh1 in this case is a fairly critical value; its smaller value should be taken for thin people, and its larger value for fat ones.

Finally, the resulting points are connected using a pattern with a smooth curve. Do not be embarrassed if the tangents to it turn out to be not perpendicular to the radii: in order for the chair to be stable, at each moment of rocking it should be on the opposite slope. When constructing, it is advisable to take the scale no smaller than 1:5.

Note: if a nirvana chair is designed, but the front ascending branch of its runners will be an elliptical arc (green dotted line in position 4), tangent to the constructed profile of the runner in volume I there.

Final balancing

It is unlikely that a novice craftsman will immediately find a rocking chair comfortable enough. Most likely, the product will need to be balanced. If the chair doesn't rock well, and when you get out of it it pushes, you need to make the rear overhang heavier. The easiest way to do this is to connect the ends of the rear branches of the runners with a low U-shaped beam of boards, with the notch facing down. Weights are placed in the recess. The lever arm in this case is long, so there is no need to hang weights. Another option, depending on the design, is a transverse pipe beam with a weight inside. But during the balancing process it will have to be removed and put back several times. If the rocker tends to fall back, you need to make the front overhang heavier. The easiest way to do this is by placing a step and attaching weights to its underside.

About materials

Rocking chairs are made primarily of wood. Metal, for all its manufacturability, low waste and greater durability in the open air, is too heavy. The influence of the chair on the overall CG turns out to be significant, the moment of inertia of the system is large and, as a result, the rocking is too sharp. Or you have to set an extremely small initial elevation of the CO above the CO, risking that the rocking chair will tip over under someone. However, we will return to metal rockers when we consider individual samples.

Plywood is a completely different matter, especially for novice woodworkers. Firstly, when making the parts of the rocking chair with 3-layer glued ones, you can only use a jigsaw to make accurate and strong tongue-and-groove joints, on the left in the figure, if you follow the following. rules:

- Plywood for the middle layer is taken twice as thick as for the outer layers. For example, if you need a total thickness of 20 mm, then glue 5-10-5 mm.

- The parts are assembled from blanks using 2-component waterproof glue. If it is on PVA, be sure to reinforce it with small nails.

- The connections are assembled with gluing (wedging in this case is unacceptable) and reinforced with diagonal pairs of self-tapping screws on both sides.

- The supporting surfaces are protected with linings made of thin (6-10 mm) strips of hard, durable wood or dense sheet rubber 4-5 mm thick. Plywood under a concentrated load cracks very well at the end.

Secondly, plywood makes it possible to use non-standard technical solutions, eg. as on the right in Fig. Such a rocking bowl can be made from plywood, again using only a jigsaw. Comfort is high, stability is absolute, and can serve as a hanging hammock chair or swing chair. The thickness of the lamella boards is from 12 mm; connecting half-washers on poles – from 24 mm.

Note: in any case, the finished plywood rocking chair must be soaked twice with a water-polymer emulsion or liquid acrylic varnish on water based. This will not only increase the strength of the product and its resistance to external influences, but will also relieve excess residual stresses in joints and bent parts.

How to install overlays

Wear-resistant wooden pads are installed on the rocking chair runners. way:

- Turn the chair over with the runners up;

- We warm the blank plank thoroughly with a hairdryer;

- We place the workpiece on the runner and wrap it tightly along the entire length with cotton braid. Don't get burned, the wood is very hot!

- We also grab the second workpiece onto another runner;

- Once the strips have completely cooled, remove the braid bands and glue the pads with PVA on wood or with 2-component glue;

- We attach the ends of the planks with small nails until the overlays fit snugly along the entire length. Place washers or pieces of plywood under the nail heads;

- Once the glue has completely dried (2-3 days), remove the temporary fasteners. We drill blind holes for screws and secure the ends completely;

- We fill the holes with the fastener heads with putty made from sawdust of the same tree, thickly mixed with PVA.

Note: The linings need to be secured with metal hardware only at the ends. Otherwise, when the lining wears out during use, the fastener heads will stick out and begin to scratch the floor.

Examples of rocking chairs

Metal

Let's start our review of rocking chairs with metal ones, because... making rocking chairs out of it is justified in few cases. Forged rocking chairs imitating classic wicker ones from wicker or rattan, as required special equipment, forges and resp. We don’t touch qualifications. But a metal rocker “like a braid” can be made by welding from profile pipe; preferably elliptical section. In this case, you need to choose the kinematic diagram of the nirvana rocking chair as the least sensitive to the excessive elevation of the CO above the CO; it also corresponds well in design to wicker rocking chairs, see Fig. In order not to increase the moment of inertia, the seat is made of braided cables, belts, etc.

It also makes sense to make garden tumbler rockers from metal, see below, due to its strength and resistance to wear. But a welded frame like the one in pos. 1 pic. on the right – the solution is not optimal, it is too complex, labor- and material-intensive. Much easier to do steel frame garden rocking chair, Concept type, pos. 2. Pipe – round from 40x2. The bed itself can be sewn like a hammock; balancing - by changing its tension and, accordingly, sagging. As a result, the work and costs are much less than repeating the established forms of rocking chairs that come “from the tree,” and the comfort is no worse.

Here we can see another interesting option: the frame of a rocking chair Concept made from... gymnastic hoops. Just not aluminum or propylene, but carbon fiber (carbon). Strength is monstrous, durability is absolute, weight is negligible. The same cannot be said about the cost, however.

Vanka-Vstanka

IN Lately gained popularity garden rocking chairs- tumblers. If you lean back completely in this one and tuck your legs, it falls back almost 90 degrees without losing stability; the rider will find himself lying on his back with his knees at the zenith. And if you stretch your legs forward, the rocking chair - the vanka-stand-up chair becomes its normal position and then you can rock as always.

The Vanka-Vstanka toy with a spherical bottom sways quite sharply. Comfortable rocking of the tumbler rocker is achieved by profiling its runners according to a complex law. It will not be possible to build their sidewalls “school style”, as described above. You need to be guided by proven samples and draw markings on the grid, see fig. The inset version, with cladding made of planks 30-40 mm thick, is more expensive, but less labor-intensive. It also allows you to increase the length of the rocking chair by installing intermediate supports-runners.

Note: wooden balls are placed on the protruding ends of longer rods (1050 mm) and form handles for rocking and carrying.

Rocking bench

Rolling your heels into the sky, throwing your hands behind your head and admiring the clouds floating in the blue heights through the fluttering foliage is a heavenly pleasure, but it doesn’t suit everyone. Some people want to look more impressive while relaxing. This is more suitable garden bench– rocking chair, see fig. It's a little difficult to swing on it, it's too big own moment inertia, but it also swings for a long time. The maximum span between supports with runners is 750 mm with cladding made of 40 mm thick slats. The back covering is decorative.

Sun lounger with awning

Both those and other requests will be satisfied by a garden rocking chair on elliptical runners and with an awning. The dimensions of its sidewalls are given in Fig. their material is 24 mm plywood. The width of the bed is up to 900 mm, its covering is made of 50x50 slats. The sidewall areas, indicated by gray circles, are connected by round wooden crossbars with a diameter of 60 mm or more.

Rocking chair

We are not talking about rocking horses here; they are toys, not furniture. But it’s also not harmful for children to rest while rocking, so it makes sense to give your child a rocking chair. Its proportions will be slightly different than for adults, due to the influence of the square-cube law.

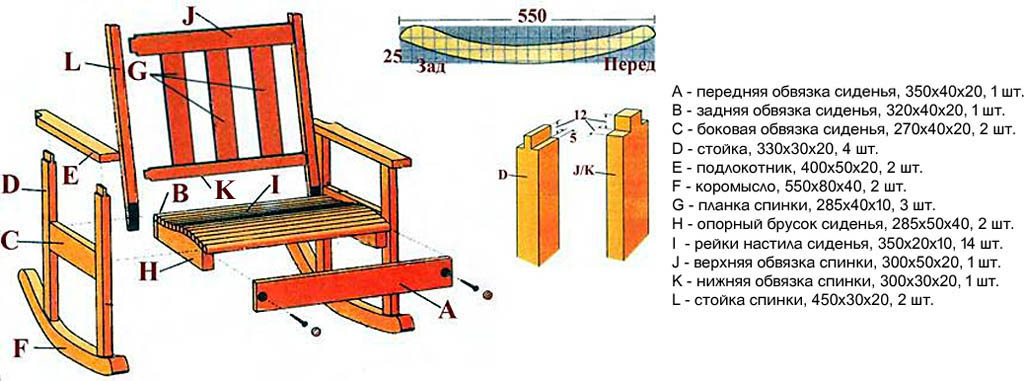

Device baby rocking chair, its assembly diagram and parts specification are given in Fig.; material – wood. It will not be difficult for a more or less experienced home craftsman to build a rocking chair for a child, guided by these data, and beginners can first watch a master class on making almost the same children's rocking chair.

Video: DIY rocking chair for children

The most complex and important parts are the runners:

Manufacturing of remaining elements and assembly:

Armchair– the rocking chair combines three undoubted advantages. Firstly, this is an original and beautiful part of the home interior. Secondly, a simple and at the same time effective health simulator. Thirdly, it is surprisingly comfortable to relax in, read a book or indulge in sweet, addictive and enveloping laziness.

Since the statement that all diseases stem from nerves is largely true, a rocking chair can become a unique pill, a miracle cure for many diseases.

Rhythmic, uniform and calm swaying puts the human nervous system into some semblance of a trance - the body calms down, relaxes, but the parasympathetic nervous system just the opposite - it is activated.

A person relaxes, distracted from the daily routine and obsessive thoughts. A relaxed mind is “lazy” to control the body, the muscles relax, beginning to fully rest and recover, accumulating a reserve of strength.

A rocking chair will help overcome sleep problems, because measured rocking is the same manipulations that a mother performs when rocking her child to sleep. cradle. Just half an hour in a rocking chair - and deep healthy sleep will take you into his arms.

A rocking chair will help patients with tachycardia - rocking seems to set a certain uniform pace to which the heart adjusts. It trains the vestibular apparatus - after it it is easier to endure long trips in a car, train or plane.

Today, rocking chairs are made from different materials, but our most popular products are from rattan and vines.

What to make a rocking chair from: selecting materials

To make a reliable, strong and durable rocking chair, you need to use quality wood – coniferous varieties, oak or larch. Often, to simplify the work, plywood is used - its sheets are not only easy to saw to obtain a part of the required shape, but it is also quite plastic and lends itself well to further processing (sanding, painting).

The choice of material is almost entirely determined by the location where the rocking chair will be placed. An outdoor rocking chair must have additional protection and treated with antiseptic agents that minimize the impact of adverse aggressive natural factors (frost, rain, snow) and will allow you to maintain aesthetic appeal for as long as possible.

![]()

Advice! Rocking chair for dachas It should not be sheathed with fabric or foam rubber - after exposure to rain it will have to be dried thoroughly, otherwise the fabric will rot and disintegrate. It is better to use a blanket or removable ones

A plastic chair and wooden runners combine to create a stylish and comfortable rocking chair

How to make a rocking chair with your own hands: the most affordable options

The main part of the rocking chair design is two runners (skis) that have an arched shape, due to which, in fact, the chair can rock. These runners can be short or long. In chairs with long runners, the depth and amplitude of the swing is quite large; a person goes from a sitting position to a reclining position. Rocking chairs with short runners provide a calm and sedate rocking motion, which is why they are especially popular with older people.

To make a simple rocking chair, you don’t even need detailed drawing rocking chairs. It is enough to take a ready-made, for example an old, chair (1) with wooden legs. Let's make two supports (2), for this we make two elements from bars that will have the same curved base. We also saw out the cheeks (3), which we later use as the bottom for the chair legs.

For each leg of the original chair, we cut out two limiting bars (4) - a total of eight. We nail the appropriate stops at the required distance for each support for all legs. We screw in three (6) furniture bolts from the outside of both supports - this will give the chair stability and ensure safe swinging. Prepare an end plate (7) for each limiting timber

Plywood rocking chair

For plastic modeling, plywood is the most favorable material. Using a jigsaw, you can get a design that will greatly simplify the process, because structurally it combines the two most important (and most difficult to manufacture) elements of a rocking chair - the runners and the sides. In addition, the absence of joints significantly increases the strength of the structure.

For production we will need:

- jigsaw

- screwdriver

- plywood – sheet at least 15 mm thick

- oak (pine) slats with a cross-section of 10x50 mm - about 20-35 pieces, the length depends on the manufacturing option - a single or double chair. For a single seat, the length of the rail is 1200 mm.

- timber (pine, preferably oak) – 30x50 mm, 3 pieces, equal in length to the slats

- self-tapping screws

We draw a pattern on graph paper, transfer the design to plywood and cut out the side panel with a jigsaw.

After this, we sand all the parts and remove small chamfers. If the rocking chair is intended for a summer residence, Special attention the ends will be required - they require maximum protection from moisture. Therefore, the ends of all parts are impregnated with hot drying oil, after which the wood fibers are slightly flattened with a hammer - this way the moisture will be absorbed much less. Before the beginning general assembly The processing-varnishing procedure for the ends must be carried out twice.

We mark holes for connecting bars (tsars) at the foot, middle part and headboard. To achieve maximum accuracy, after preliminary marking, the sidewalls are aligned and a hole is drilled. The drawers are secured with Euroscrews and additionally secured with wood glue. After this, we evenly fasten the slats onto the already assembled frame with self-tapping screws. After completing the assembly, you need to fill the holes above the screws, sand all the parts again with fine sandpaper, treat them with an antiseptic, cover them with stain (if you like) dark colors wood) and coat the resulting chair with waterproof varnish.

If it is possible to use an angle grinder and welding machine, you can assemble a metal frame. To do this you will need a steel corner (20x20x3 mm) and a steel strip (thickness 4 mm, width 40 mm). After assembly, the frame is painted, after which holes for self-tapping screws are drilled along the entire length of the seat and backrest, which will be used to fasten the wooden facing strips.

Advice! Before assembly, be sure to treat the metal parts with an anti-corrosion compound.

A rocking chair is always associated with a quiet, peaceful evening dedicated only to relaxation.

Of course, you can use it at any time of the day, but you won’t be able to relax the way rhythmic and rocking movements allow you to do anywhere else.

That is why this piece of furniture today can be found not only in the garden, but also in reputable offices. Moreover, many companies equip break rooms with them.

A rocking chair allows you to relax not only the body, but also the brain.

Scientists have long proven that rhythmic, repetitive movements, such as walking or rocking, help you calm down, concentrate, and put your thoughts in order.

The most difficult tasks are solved much easier in such an environment.

If you know at the dacha, then a high-quality, fresh lawn will always be a source of pride and admiration for your guests. Details in the article.

Sunny and varied astilbe: planting and care open ground depending on the plant variety. What for different types astilbe?

Ideal choice for a summer residence

A mandatory part of any recreation area on the site. The most popular models are made from wicker, artificial and natural rattan and forged.

Their advantages:

- beautiful appearance;

- strength;

- resistance to moisture and ultraviolet radiation;

- durability.

Of course, it is in the garden that a rocking chair is most appropriate. It can be installed in a gazebo, on or open veranda. Models from natural materials fit harmoniously into any landscape design.

They look beautiful and bright on modern estates Garden swing on metal and textile runners. For areas with log houses or timber buildings, it is more suitable wicker furniture or from an array.

If the design of the dacha is dominated by buildings and decorative elements made of stone - you should pay attention to artistic forging or cold bending.

Unusual design solutions can be a striking accent in the landscape. This rocking chairs for two, or original beds that can easily replace the usual sun loungers.

Variety of options

The history of the rocking chair goes back a little more than two centuries. And this wonderful idea belongs to a talented person, inventor and politician - Benjamin Franklin.

But in Europe it became famous and widespread only in the middle of the 19th century. Today, models on skids are popular. It is precisely these rocking chairs that can be found on the pages of classics describing the life of the aristocracy and in modern gardens.

Relatively recently, it appeared completely new design. Sliding rocking chairs without runners. They are ideal for interiors with delicate flooring.

The materials from which such furniture can be made are amazingly diverse:

- It can be hard wood.Such chairs attract with their massiveness and reliability, while the variety of shapes and design solutions it's limitless here. It is among the wooden models that you can find both golden classics and avant-garde.

- Rattan and wicker – traditional material for the manufacture of rocking chairs. Their distinguishing feature– lightness and delicacy. Today, wicker furniture can be made from artificial material. It is practically no different from models made of willow or grapevine or rattan, but is not afraid of moisture.

- Metal– the material is plastic, but heavy. Wrought iron furniture always looks luxurious. But, the weight of such products is significant. That is why, even in the garden, it is better to use them only on stone or concrete areas. Metal runners will sink into the ground and damage the lawn turf, wooden boards they also leave noticeable marks.

- Gaining popularity today plastic models. They are durable, resistant to any vagaries of weather and bright and modern design. Equally important is the fact that models made from this material are the most affordable.

Level hands and desire

You can also make a rocking chair with your own hands. This will require, first of all, desire and a little time.

The most popular materials self-made such furniture - wood, plywood and metal. What exactly to choose, everyone House master decides for himself. It depends on the availability of material and the ability to work with it.

Photo selection with ready-made rocking chairs that you can make yourself:

We use wood and plywood

This is perhaps the simplest and affordable option. To work, you will need tools that almost every home craftsman has.

The photo shows a drawing of a plywood rocking chair

You can watch how to make a rocking chair with your own hands from wood and plywood using only an axe, a plane and a saw in the presented video, but such work requires extensive experience in woodworking. This video is the first part of a whole series of instructions. In any case, this is a quality and real experience from a craftsman who can really show you how to make this piece of furniture yourself.

If you are not used to getting by only hand tools, then for work you need to prepare:

- jigsaw;

- screwdriver;

- screws and drills of different diameters;

- sandpaper of different grits for processing finished parts.

The easiest way to make a rocking chair out of wood with your own hands is use an old but durable chair. Its legs are shortened, and the resulting structure is mounted on hardwood runners.

To make it new and non-standard appearance it can be braided with leather or plastic tapes or sew an unusual cover.

More interesting models The easiest way to make it at home is from plywood with a thickness of at least 15 mm. The general idea is quite simple. Sidewalls are cut from sheets according to a pre-calculated pattern. For example, it could be like this:

Cutting out the sides

The edges of the plywood are carefully processed. The two parts are connected to each other by three bars 30x50x600mm.

The upper part is laid out with thin boards or slats of plywood with dimensions of 10x50x600 mm (the length can be longer if the slats need to protrude beyond the edge of the sidewalls), which are attached to the end with self-tapping screws.

To avoid cracking and delamination of plywood, it is recommended to pre-drill it at the fastening points with a small-diameter drill.

To avoid cracking and delamination of plywood, it is recommended to pre-drill it at the fastening points with a small-diameter drill.

It is also worth making recesses in the facing strips so that the heads of the hardware are recessed.

If desired, they can be hidden with special plugs to match the wood or putty.

After assembly, the wood can be tinted and varnished or painted in any color.

Metal chair

Metal is a difficult material to process. And if there are no forging skills or equipment for making bent elements, then only simple models chairs, but they can be no less interesting.

First of all, a metal frame is made from a corner, pipe or profile.

After this, all parts are coated with an anti-corrosion compound. Hammer paints look very nice. What will it be decorative finishing- depends on the desire and imagination of the master.

For example, the seat may simply be made of wooden planks. Or the model may be soft. For this purpose, the seat can be braided with a regular luggage belt.

Sew pillows for the back and seat and hide everything with a common removable cover. It is also quite easy to braid the metal frame with willow vine. For this you will need the most basic knowledge on wicker weaving, which can be found on the Internet.

Your hand is the ruler

Although only two are presented in detail simple options, they can be implemented in different ways. Based on the recommendations given, you can collect wooden chair this type of rocking chair.

In the first video we see drawings for making a rocking chair with your own hands:

On the second there are tips and assembly instructions:

As you can see, in this master class more simple form sidewalls, but special attention is paid to design. Such a chair will look luxurious not only in the garden, but also in the office.

Experiment is the engine of evolution

By experimenting with the base of the frame, you can make it according to similar principle and other models. For example, with armrests.

If desired, this can be a whole furniture group for two people. This model not only looks very original, but will also allow you to relax in pleasant company.

Armchair for two persons

Moreover, all you need is a little imagination and the usual rocking chair turns into a comfortable couch with an awning. You can relax on it in any heat. And if you equip it with a canopy made of mosquito net, then sleep on summer nights in the fresh air.

No less interesting and unusual are the ideas of home craftsmen for models on metal frame. They can be openwork and almost weightless.

Or simple, concise and modern.

To make such a model you will need welding and a pipe bender. Its design is extremely simple. And the seats can be either wicker or sewn from dense material.

From metal pipes You can also make a rocking chair in a classic style.

Rocking chair in classic style

No less interesting is the model in the patchwork style, in which a metal ring is taken as the basis of the seat. This chair is ideal for a country style cottage.

Rocking chair in country style

Making a rocking chair with your own hands is not just about creating an exclusive item, but an opportunity to make furniture that will be comfortable for you and will suit the design of your site. This is a great chance to show imagination and creativity.

What else to read

THE LAST NOTES

- Potatoes with mushrooms in a pot in the oven with turkey

- Features of work on the development of speech of first-graders during the period of learning to read and write

- Summary of an individual speech therapy lesson on sound automation l Individual speech therapist lesson on sound automation l

- Summary of an individual speech therapy lesson at school VIII type "Preparation for sound production" Sound production w lesson summary

- The role of tongue twisters in speech development