Chopped log cabin. Projects and features of the chopped bath

SORT(by area, construction cost, rating, date)

total area 40 m²

Project cost RUB 15,290

Construction from RUB 508,944

total area 130 m²

Project cost RUB 21,450

Construction from RUB 845,950

total area 82 m²

Project cost RUB 18,290

Construction from RUB 494,197

total area 35 m²

Project cost RUB 15,290

Construction from 390 780 rub.

total area 155 m²

Project cost 25 000 rub.

Construction from RUB 1,149,793

total area 184 m²

Project cost 25 000 rub.

Construction from RUB 1,352,330

total area 112 m²

Project cost RUB 21,450

Construction from RUB 950,210

total area 128 m²

Project cost RUB 21,450

Construction from RUB 1,012,091

total area 155 m²

Project cost 25 000 rub.

Construction from RUB 1,149,793

total area 136 m²

Project cost RUB 21,450

Construction from RUB 1,042,084

total area 150 m²

Project cost 25 000 rub.

Construction from RUB 1,307,698

total area 150 m²

Project cost 25 000 rub.

Construction from RUB 1,307,698

total area 112 m²

Project cost RUB 21,450

Construction from RUB 1,051,359

total area 112 m²

Project cost RUB 21,450

Construction from RUB 1,051,359

total area 154 m²

Project cost 25 000 rub.

Construction from RUB 1,005,493

total area 154 m²

Project cost 25 000 rub.

Construction from RUB 1,005,493

Projects favorably combine aesthetic and technological components. A log processed by hand fully retains its protective natural properties and has a longer service life. Log houses and baths look extremely beautiful, with a reference to distant times, when our ancestors did not know others. building materials and skillfully cut amazingly beautiful buildings. Baths, chopped from a log: we build once and for a long time. In most cases, baths are built from conifers wood, as they have all the necessary characteristics - strength, resistance to moisture, temperature extremes, long service life. Pine, spruce, larch, cedar will fill the air with a wonderful and healing aroma. The construction and decoration of the bath will require no less attention than the construction of a residential building. Each of technological stages must be carried out in full compliance with the applicable building codes. Our website contains a large number of photo and video materials about how they cut and build baths. However, the information is only useful for those who have certain skills in working with wood. After all, it is not easy to work with a log - the material is alive, plastic, breathing. It is wiser to entrust this work to our masters, who are ready to build a turnkey chopped sauna for you, the price of which will certainly suit you. A log chopped by hand - what are its features that are beneficial for the consumer?

. Maximum safety protective properties blanks. Only thin is removed from the log upper layer, which is the most loose and fragile, the structure remains intact.

. The highest heat-saving qualities due to the integrity of the product.

. Much more stable resistance to temperature extremes, frost, rain.

. Low probability of crack formation.

. The careless, as if deliberately sloppy processing of logs gives a special aesthetic charm to the bathhouse and the log house. You can completely do without the use of finishing, which will reduce the total cost of construction work.

In order for a wooden chopped bath to turn out to be truly solid and durable, it must be built by masters of their craft who can take into account the characteristics of each log and use them most productively.

Stages of construction of log baths on a turnkey basis:

- design

- foundation building

- installation of a log house

- installation of floor beams, flooring and ceiling boards, installation of rafters, battens

- insulation of the roof, its covering with tiles.

Since chopped log cabins of houses and baths give mandatory shrinkage (up to 10%), Finishing work are carried out after the required time has passed, at least after a year:

- interior decoration

- warming

- electrical installation

- impregnation with special protective equipment(if it hasn't already been done).

For the best and strong connection of logs, mezhventsovye connections are made with the most optimum width and form longitudinal groove. Log cabin is carried out different ways, at the discretion of the master - most often "in the bowl" and "in the paw." Baths from chopped logs, can be implemented both in the version of one-story buildings with a veranda or terrace, and in the version with attic floor.

Do you want to buy a chopped bath? Contact us!

The chopped bathhouse is a warm, strong, absolutely ecological building, which will bring invaluable benefits and give health for many years.

The funds invested in its construction will return a hundredfold. However, this exclusive option, which not every developer chooses, since the total cost of construction is quite high. What is the price of such a building? Given the complexity of processing the material and the amount of time spent on this work, its cost cannot be too low. The assembly of a log house is also more complicated and takes more time than the assembly of a log house from rounded logs or profiled timber.

Our company is a leader in the construction wooden houses for many years. One of the directions is the construction of baths from chopped logs, with an area of 9 m². You have the opportunity for a small cost to build a wooden sauna on the territory of your site, you can choose from already ready-made options and order individual design based on personal preference. Such baths combine the characteristics of construction ancient baths and have been popular for over 100 years. This is due to the availability of materials used in construction.

The quality of the materials and workmanship of the bath ensures that heat is retained, the risk of mold or insect infestation is reduced, which ensures long term services.

Chopped baths won a special reverent love among the inhabitants of our country many centuries ago. The urban rhythm of life only increased the desire of people to retire and relax their souls in a bathhouse made of chopped logs. At the same time, such structures also bear the memory of the people, as well as Russian traditions. It is no coincidence that we can see colorful log baths next to modern elite buildings.

The construction of a bath begins with the preparation of logs, there are several ways to do this. The first method is to remove only the bark from the tree trunk, and is called debarking. Such logs are distinguished by their slightly rough appearance. The second method involves stripping with a scraper, a special tool for wood. The tree acquires aesthetic beauty. The third way is to process the trunk with a planer, visually there is a resemblance to a rounded log, but at the same time all the technical parameters of the material are preserved.

For all questions of interest and calculation of the cost of the bath, you can contact our managers. They will provide you full information and help you choose optimal materials for construction. Already turnkey solutions presented on our website, if none of them suits you, we will definitely help in solving and creating your project. We guarantee the durability of the baths we build and guarantee the quality and environmental friendliness of materials.

many owners country houses and cottages, if there is free space on the site, a chopped bath is additionally erected. After all, what can compare with the pleasure that gives the opportunity to take a steam bath in your own steam room, and then sit with friends, family on the veranda. The tradition of bathing is kept at the genetic level of the Russian people. And steaming in a chopped bath is a double pleasure.

In Russia, every household had log baths for a long time, and there were craftsmen to cut buildings from logs in every village. With the modern variety of building materials, the popularity of wooden structures is not decreasing, but increasing. This is primarily due to the environmental friendliness of the material, as well as a special aura.

What is a chopped bath

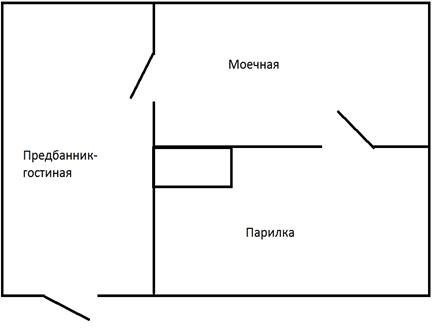

Chopped bath, erected according to individual project, can be either one-story or two-story, with an attic. To the traditional areas of the building, such as:

- dressing room;

- steam room;

- restroom.

To the project often add a veranda. It is good to sit on the veranda after the steam room, enjoying the view of the garden. It is better to entrust the chopped sauna project to the craftsmen, since the construction of objects from solid logs has its own specifics and consists of several stages. You can build a log house from profiled timber, which requires less time. But a log processed by hand retains its living structure.

To the project often add a veranda. It is good to sit on the veranda after the steam room, enjoying the view of the garden. It is better to entrust the chopped sauna project to the craftsmen, since the construction of objects from solid logs has its own specifics and consists of several stages. You can build a log house from profiled timber, which requires less time. But a log processed by hand retains its living structure.

Design and construction of log baths

Chopped bath is being built from coniferous trees- pine, spruce, larch. It is they who give a unique aroma to the air, performing an additional disinfecting action with phytoncides.

With special care suitable for the choice of logs, their quality and size. Cutting time also matters. A tree cut down in winter has greater density and shrinks less when the annual temperature changes.

With special care suitable for the choice of logs, their quality and size. Cutting time also matters. A tree cut down in winter has greater density and shrinks less when the annual temperature changes.

chopped bath, built from logs, has the following advantages over brick and concrete:

- Due to its low thermal conductivity, wood retains heat well.

- The rest room, the veranda do not overheat in the summer heat.

- The walls of the steam room, built from conifers, emit phytoncides, filling the air with a healing aroma.

Construction stages

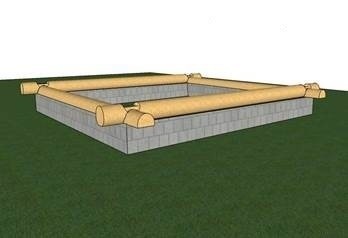

Log processing and log collection perform on a level open area close to the harvesting site. Masters manual felling with a special tool, only the bark is removed, leaving a dense top layer, which is called sapwood. Preservation of the top layer increases the service life of the building, as the logs become more resistant to atmospheric influences and temperature changes.

The next step will be selection of logs by size according to the project. Depending on the size of the future log house, suitable logs are selected along the length. All logs have length different thickness, so they are picked up in a run, to compensate for the difference in diameter.

The next step will be selection of logs by size according to the project. Depending on the size of the future log house, suitable logs are selected along the length. All logs have length different thickness, so they are picked up in a run, to compensate for the difference in diameter.

Then start cutting logs(crowns) to ensure their snug fit according to the project. Masters cut the necessary grooves, depending on the chosen method of laying, then proceed to laying them into the walls. The first crown rests on the foundation with a non-flat side, but a figured one. On it, a ledge is cut from the front side - a dropper, which protects the junction of the foundation and the crown from moisture.

Chopped bath assembly

Assembly in progress without caulking grooves. All this preliminary work is carried out within two to three months.

Then logs are marked according to their placement and the design of the chopped bath, log house dismantled and transported on the permanent place. Here, the bath is assembled according to the project on a pre-prepared foundation. The log house is caulked, the construction of rafters and roofs is being carried out. Chopped bath shrinks within a year. Therefore, the log house left to shrink for a year.

One year after shrinkage, grooves are again caulked and finishing work is being carried out, electrical wiring is being laid. Held special impregnation logs to prevent rotting and damage by wood pests. Optionally, the walls inside and outside the building are additionally sheathed. But you can save money and do without finishing. Moreover, untreated walls, while maintaining natural look logs, attached special charm.

One year after shrinkage, grooves are again caulked and finishing work is being carried out, electrical wiring is being laid. Held special impregnation logs to prevent rotting and damage by wood pests. Optionally, the walls inside and outside the building are additionally sheathed. But you can save money and do without finishing. Moreover, untreated walls, while maintaining natural look logs, attached special charm.

Chopped baths give a special charm suburban area, although the cost of their construction costs a rather large amount. Like any handicraft, a hand-cut building will cost more than one assembled from pre-grooved profiled timber. Each chopped bath carried out on an individual project taking into account the location and the wishes of the customer.

By visiting our website, you will find many useful information for the construction of a chopped bath. The main thing on which I wanted to focus the attention of the readers of the site was the fact that to draw up a project and construction should be trusted to professionals.

Is there anything in this world that is comparable to the pleasure that a few hours spent with family and friends in your own steam room deliver? A real chopped bath, built with my own hands, - the pride of any owner. In this article, we will briefly tell you about the basics of building a chopped sauna with your own hands at all its stages: foundation, choice of wood, lower crown, walls, roof, floor, and several typical layout options.

Foundation for a chopped bath

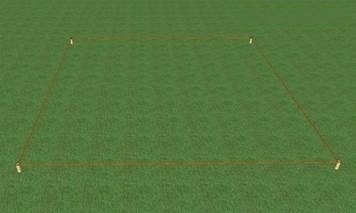

Construction work begins with the study of the site, carrying out all the necessary calculations and designing a bath. In our case, given that it will be a log house, a simple draft design is sufficient, in which the main parameters of the future building will be included. As soon as the dimensions and shape of the structure are indicated, the exact location for the bath on the site is determined, you can begin to build the foundation.

Appearance strip foundation everyone knows - these are concrete tapes on which they rely bearing walls. The base of the strip foundation should be 10 cm wider than the wall - this will be more reliable and stable.

First you need to mark up the site:

Clear the area from debris, mark the place where the first corner of the building will be, drive in a peg and mark it with a triangle or in any other way. On one side of the mark, measure the length that, according to our calculations, the longitudinal wall of the structure has. On the other side, measure a distance equal to the transverse wall in the center lines. Having determined the points at which the walls will end, drive in the second and third pegs. Calculate the place opposite the first corner of the bath, drive in another peg and move the triangle. Ideally, you should get a rectangle, the difference between the diagonals of which does not exceed 2 cm.

After marking, we begin to dig a trench. If the soil in your area is sandy, then it is enough to dig a ditch 50-60 cm deep, if the soil is clay, you can deepen the ditch. After the trench has been dug, it needs to be surrounded by an edged board, reinforcing the edges - this will be the formwork. As a rule, for such work apply edged board with a section of 150 by 25 mm. When installing, please note: the height of the formwork must exceed the height of the foundation by 10-15 cm. When wet or clay soil it is better to prepare a good sand cushion.

Edged board - best option for formwork: this material has a flat surface, which can significantly reduce the cost of subsequent facial finishing of the finished foundation.

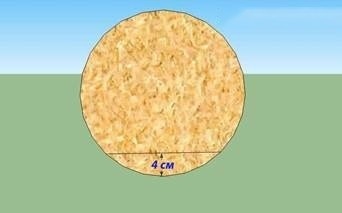

Choice of wood

Properly selected wood is half the success. As a rule, chopped baths are erected from deciduous and coniferous species, distinctive feature which are strength and moisture resistance. It can be larch, pine, spruce or oak. For the construction of a bath, it is recommended to choose well-dried logs with a diameter of 200x250 mm. The moisture content of wood should be within 10%. More at your choice 100% sauna beams

The basis of the chopped bath: we put the lower crown

The lower crown stands on the foundation, in close proximity to the ground and gets wet more than other crowns during precipitation. Before laying the first lower crown it is necessary to provide waterproofing of the foundation in order to prevent the walls in the lower part of the building from getting wet. To do this, it is enough to lay 2 or 3 layers of bituminous waterproofing material between the foundation and the logs.

The lower crown, which is called the salary, is made of thick logs. For greater reliability and strength of the structure, the salary is often made from a rock that has increased resistance to decay and moisture - larch or oak.

The first crown can be laid in one of the two ways described below.

- First way. Two logs are laid on the foundation parallel to each other, having previously cut off 4-5 cm from each for a snug fit. A heater is laid between the log and the waterproofing - it can be tow, jute or moss. On two free sides, two more logs are also laid out parallel to each other, strengthening them on the first hewn logs.

Benefit: The logs are minimally processed and remain solid except for 4-5 cm removal, making the flashing durable and strong.

Disadvantage: the appearance of too large gaps between the foundation and the logs, which must be sealed with bars, bricks or log particles. Alternatively, you can pour the foundation, with different levels perpendicular sides.

- The second way. Choose four logs for the crown. Two of them are cut off by half, the remaining two - by 4-5 cm. With this installation, there are no gaps between the crown and the foundation. At the junction, the logs are connected using the method corner connection"in ohryap".

Advantage: no gaps and tight fit to the foundation.

Disadvantage: part of the log is removed, which violates its integrity and makes the wood less durable.

Important: To reduce the risk of rotting of the lower crown, that part of the hewn logs that come into contact with waterproofing materials, before laying it is desirable to treat with an antiseptic.

Walling

As soon as the lower crown is ready, you can start building walls - you need to lay logs horizontally, forming crowns. At this stage, you should Special attention give the corner connection of the walls, on which the solidity of the entire building depends.

Types of corner joints of logs

There are two ways to connect logs - a corner with a remainder and an angle without a remainder.

Corner with the remainder - the logs are connected in such a way that, when connected, they protrude beyond the walls of the structure by 20-30 cm.

Advantage: easy to manufacture, does not require additional insulation and virtually breathable.

Disadvantage: material consumption is 10% more than with the "corner without residue" method.

Corner without residue: the logs are connected to each other by wooden locks, cut down at the ends. At the same time, the remains of logs do not protrude beyond the walls of the building.

Advantage: aesthetics.

Disadvantage: high labor costs and the need to additionally insulate the walls from the outside. In addition, if, when connecting “without a trace”, the logs are not rallied with dowels, then the log house will be less stable.

There are many types of corner joints with a remainder, but two methods are most common:

Okhryap angle: in our case, this type of cutting was used when laying the lower crown. In the upper and lower logs, recesses of the same size are selected, into which the logs then go. This method is rarely used in our time, therefore it is too difficult and long to adjust the size of the recesses and make the joints not blown. As a rule, logs are connected “in okhryap” if it is necessary that all the tops of the crown are located in the same plane.

Corner "in the bowl": simple and practical way used in the construction of walls, which even an amateur can master. The upper log enters the recess of the lower log, cut in the form of a bowl, which copies the landing part of the incoming log.

by the most suitable option for a bath, a cut into the bowl “into a fat tail” is considered: a ledge is left at the base of the bowl along the lower log, and a notch is selected in the upper log, suitable in size to the ledge.

Wall shaping

Having chosen one of the methods of corner connection, you can begin to form the walls of the bath, laying the crowns horizontally in the desired sequence. The grooves formed during laying between the crowns are filled with insulation. Traditionally, tow or moss is used for these purposes.

During the assembly process, it is necessary to mark places for windows and doors in the walls. Crowns can be made from individual pieces of logs or simply sawed logs in the intended places. It is advisable to do this immediately, because if you cut out the windows later, the logs may hang, the piers will lower and large gaps will appear between the covering log and the upper level of the piers. When the log house is installed, in the designated places with the help of a chainsaw, you need to cut openings for the door and windows.

Important: windows and doors should be floating so as not to interfere with the natural changes in the dimensions of the log house during shrinkage. To do this, spikes are formed in the lower and side parts of the opening, 6-8 cm wide and 4-5 cm high. Windows and doors are installed in door and window frames.

bath roof

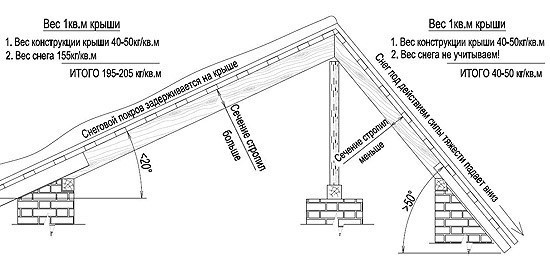

The optimal solution for a chopped bath - gable roof, which, although it will cost more than a single-sided one, will look more neat. Under the roof, you can equip a room for storing bath accessories and drying brooms.

The figure shows that the greater the angle of inclination of the slope, the less load it is subjected to during snowfalls.

As roofing material you can choose roofing material, slate, ondulin, profiled sheet, metal tile. Any will do material within the material capabilities of the owner of the bath. The angle of inclination is selected depending on the chosen roofing material.

Floor in a chopped bath

Wide selection modern materials allows you to make the floor not from wood, but from materials that are more durable and resistant to moisture. The wooden floor quickly gets wet and dries slowly, as a result of which the process of decay begins, unpleasant odors and microbes, which is harmful to health.

The most optimal option for a bath is a concrete floor covered with tiles.

Please note that the floor is made only after the installation of the sewer system.

Chopped bath layout

At the design stage, it is necessary to indicate which rooms will be in the bath and how to rationally distribute total area between them.

As a rule, the bath includes several rooms:

Vestibule, with an optimal area of 1 m2: the main function of the vestibule is to prevent the entry of humid or frosty air from the street inside, otherwise front door condensation will freeze, and it will be impossible to open it;

Locker room or rest room: according to the recommendations, the norm of the area of the locker room is determined at the rate of 2-4 m2 per person, if built small bath for 4-6 people, it is enough to allocate 8-10 m2 for this room;

Washing room: according to the norms, 2.7 m2 per person is allocated for this room, some owners combine a washing room and a steam room;

Video on building a bath with your own hands

And finally, a useful video:

We also recommend you:

The construction of a turnkey bath at low cost today is a topical issue for many residents of Moscow and the Moscow region. Our company offers the construction of a bathhouse from chopped logs according to standard solutions, as well as according to customer projects. Individual design usually costly and time consuming. Typical buildings are distinguished by their versatility and some simplicity, combined with an affordable price.

Moscow has always been distinguished by interesting architecture, and its inhabitants are accustomed to seeing around them both ancient and modern buildings worthy of the highest appreciation. Therefore, even a bath should organically fit into overall plan houses and plots.

Log bath projects

Our company is ready to offer solutions for any scale of the site. Choose standard turnkey bath projects based on your capabilities and preferences from the “economy” class to large-sized buildings. For assembly, there are no special requirements for the site, except flat surface site. The project may include gazebos, benches, barbecue areas and much more. They complement the bath complex and give the territory an attractive appearance.

Often, the future owners of the bathhouse want to place a pool nearby, as well as a closed or open terrace. No problem - we have posted on the site finished projects, which already includes all necessary elements for comfortable rest. At the same time, you can notice that the main client factor - the price - is the most attractive on the market. wooden housing construction. The choice of projects is so great that there is no need to create and coordinate a new one. Chopped log bath projects can be ordered through the website by leaving a request, or by calling the specified phone number.

The log cabin of the baths will be erected immediately after the preliminary conditions have been agreed. You can be sure that your dream of a sauna has fallen into the reliable hands of professionals in their field and will soon be realized, taking into account all wishes.

A log bath today is not at all difficult to implement, because there are ready-made ideas and projects. It is important to connect a little imagination, apply design talent (either your own or an involved specialist) and a typical project turns into an exclusive one. Here it is important to calculate the material, select the right technique construction and find responsible specialists.

At correct selection and careful control at all stages of construction, your money will not be thrown "to the wind", the construction plan will not be violated and the log cabin of the bath will appear on the site as scheduled. The result of completing the full list of works is the Tsar Bath that pleases you with its beauty, the ideal quality of your vacation spot, which is really responsible for its options - the price. We will be happy to help you with this. All questions you can ask us by phone or using the form feedback Online.

What else to read

THE LAST NOTES

- Fried cauliflower: fast, tasty and healthy Fried cauliflower without cooking

- How to fry cauliflower in a pan How many minutes to fry cauliflower in a pan

- More about personal hygiene

- Delicious chicken borscht: a step-by-step recipe with a photo (in a saucepan, in a slow cooker) How to cook delicious red chicken borscht

- Personal hygiene and human health