The main malfunctions of storage water heaters. Malfunctions of heating boilers

If the water heater does not heat the water well, check if you drain it before it has time to heat up? Depending on the model of the boiler (its volume, power of the heating element), it will take 2-4 hours to heat the water. The input voltage also matters. electrical network. If such "haste" is excluded, then you need to look for the causes of the breakdown.

Why is the boiler not heating water?

When the water heater does not heat water, the reasons may be as follows:

- breakdown of the heating element switch;

- failure of the thermostat;

- malfunctions in the electronic control unit;

- failure of the safety valve;

- the occurrence of scale on the heating element or the heating element burned out.

Checking the functionality of electrical components

First, you should check the operation of the hot water valve, and then see if the indicator lamp for turning on the boiler is working.

If the light is off and the water heater has stopped heating water, then the sequence of actions is as follows:

- The boiler is de-energized, freed from water, the housing cover is dismantled on it

- At the ends of the thermostat, you need to check the presence of incoming current. For this, it is advisable to use a special tester, and not an indicator, in order to exclude a break in the supply "zero";

- If voltage is supplied, then you need to press the thermal protection button. Did it provide inclusion? Now preventive cleaning of the heating element from scale is required - it has overheated.

- Thermal protection could also work due to the fact that it does not flow out of the tank hot water due to a broken safety valve. Keep in mind that the valve can only be replaced with a regular one - it is not recommended to install a conventional check valve here.

- You need to remove the thermostat and ring it. If it doesn't turn on, it needs a replacement. It is problematic to repair the thermostat - in most cases there are no mechanical elements in them.

When is a heater replacement needed?

When the light is on, but the water heating is very weak or absent at all, the operation constantly occurs automatic protection when turned on, then the reason why the water heater does not heat water lies in the burnt heating element. Experts believe that average term services heating element- 4 years.

The operability of the heating element is checked with a multimeter - if it shows infinity during a dial-up, then a break has occurred, and if 0, then the problem is due to a short circuit.

To replace a burned-out heating element, due to which the Ariston water heater does not heat water, you will need to turn off the water and electricity supply, drain the water from the tank and remove the protective cover. Some models of boilers will have to be completely dismantled - removed from the mounts and disconnected from the wires. The heating element is removed from the nut fasteners and a new one is screwed on, after which the integrity of the anode and rubber safety gasket should be visually checked - they may also need to be replaced.

After assembling in reverse order, check for leaks and correct supply cold water. Then you need to release the air that has accumulated inside the tank, and only after that connect it to the network.

If you do not want to deal with all the intricacies of the repair process, then contact the professionals Repairman. The master will arrive immediately after receiving the application, with everything essential tool. You will not need to look for suitable spare parts or understand electrical circuits ah - diagnostics to determine the cause of the breakdown will be carried out efficiently and quickly.

Water heater repair video if it does not heat water

2017-01-10 Evgeny Fomenko

Why the instantaneous water heater does not turn on, there can be many reasons, consider the most common malfunctions.

TEN water heater Ariston

TEN water heater Ariston Moreover, Termex Stream is distinguished by the separate inclusion of each of the two heating elements, thereby it is possible to regulate the consumed electricity and the rate of water heating. If the model is without a protective flask, scale will form on the heating element over time, which corrodes the metal and causes the heating element to fail.

You can check its serviceability using a tester by measuring the resistance at its contacts, the absence of resistance indicates its breakdown. If the heating element is broken, the easiest way is to buy a new heater, since its price is not much less than the device itself. But if you decide to change the heating element, you should remember that its power must be exactly the same as that of the original one.

They burn out most often due to the fact that the device turns on at a low pressure, the sensors do not have time to work, as a result, the heating element burns out. To reduce the impact of aggressive impurities in the water, a filter should be installed.

Incorrect installation of the unit also leads to the combustion of the heating element. It must be installed strictly according to the manufacturer's recommendations so that the thermostat probe is always in contact with the coil.

Water heater pressure sensor Thermex

Water heater pressure sensor Thermex The microswitch ensures the feed electrical energy to the heating element. The membrane, under the influence of various impurities and salts contained in water, under the influence of low temperature, if the device is used in the country, loses its elasticity over time and cannot act on the microswitch.

What to do in this case? There is only one way out - to replace the membrane, it is better to purchase a silicone one, it will last you longer.

For example, in models Gorenie, Ariston, the working pressure should be 0.6 MPa. If the pressure is less, it is necessary to install a pump. In some cases, it is enough to install the heater lower, as close to the pipe as possible.

Boiler temperature sensor and gauge

Boiler temperature sensor and gaugeThere are also reverse situations when the device does not turn off. This can happen when the switch button melts, if the temperature sensor malfunctions, the relay contacts can stick and the heating element does not turn off when the water supply stops. When using EWH for reliable and long work it should be remembered that first the water is turned on, and then the electricity is turned off in the reverse order.

A properly manufactured water heater is noticeably different from any other water heating equipment. Low quality. These differences can be seen by paying attention not only to the beautiful appearance, but also by comparing the number of required functions.

Considering special details that increase the service life and extend the operating period, it's harder to make a mistake and make incorrect choice. However, it is impossible to take into account all the nuances and shortcomings, because each model has its own weaknesses.

The manufacturer, no matter how much it wants to, cannot foresee all situations and hide some defects, therefore, by choosing such equipment more responsibly, and paying attention to all scratches, cuts, loose parts or excessive noise, you will protect yourself from fakes.

Common Causes of Problems

But any technique breaks down over time, because nothing is perfect. To extend the life of the equipment, you need to know common causes breakdowns. The most common malfunctions of water heaters:

- Scale. Appears due to hard or rusty water.

- Extra noise or poor quality work. It usually happens due to improper installation of the device or when used in violation of technology.

- blockage. Occurs due to the lack of special filters.

- Work failures. This is due to sudden power surges.

Incorrect installation or installation with gross violations most often occurs air bag . It prevents water from covering part of the heating element, and this is fraught with fire. Such malfunctions of the water heater can be prevented.

It must be remembered that horizontal models must be installed horizontally, and vertical - vertically. You can find out about this malfunction by the case: if it is deformed and there is a smell of burnt plastic, then this error must be localized as soon as possible.

Why does a water heater fail?

If you did not purchase additional components when purchasing this unit, you may encounter another malfunction of the water heater - cracking of the shell from the inside. This is due to the lack of a safety valve.

Filters and special means to soften the water you also need to purchase. Otherwise, your unit may be in danger of overheating, blockage important elements, quick failure, spontaneous draining of water and much more.

To avoid external mechanical damage, it is necessary to install the water heater in right place and as recommended by the manufacturer.

How to prevent problems?

Water heater malfunctions occur mainly due to untimely cleaning technician and. By cleaning the entire system at least once a year, you can avoid overhaul or replacement, which is really cheaper.

During this ingenuous procedure, all internal elements are thoroughly cleaned, unnecessary dirt and rust are removed from especially important details, there is a thorough inspection and check of equipment for depressurization of the hull. It is better to do all this in specialized centers or in services, since it is there that professionals in their field work, with the whole set the right tools. They will do their job without damaging the body of the unit.

Video instruction - how to repair a water heater with your own hands

User Questions:

- Hello. This question is of interest to the Thermex RZB-L50 boiler, when heated after 2 years of operation, hot water began to flow with air. Cold water flows normally.

- what to do, what could be the reasons for water flowing from the intake pipe in the water heater

- Hello! I bought a Termex boiler 2 weeks ago, the first week after installation it worked fine, then when it was plugged into the outlet, it began to knock out the meter. When plugged into another outlet, the boiler works. What is the reason? I would be grateful for your help.

Design of all water heaters despite the fact that there are a lot of different modifications on sale, it is almost the same. The difference is in the materials used, the power of the heating elements, volume and design. And the crashes are the same. The boiler device is quite simple. An electric water heater consists of two, usually steel, tanks: internal (working) and external. The inner tank, as well as the outer one, can have different coverage for rust protection or can be made from of stainless steel. The thickness also varies. Here, the thicker the better. Between the tanks there is a thermal insulation layer of polyurethane foam. In the body are

two nozzles: a short one with a divider for supplying cold water and a long one for taking hot water. The electrical part of the boiler is mounted on a flange and consists of a heating element, thermostat, signal lamp and magnesium anode.

The temperature gauge is used to indicate the heating or cooling process. A safety valve is always included with the water heater, which must be installed on the cold water supply pipe during installation.

If you install electric boiler on one's own, will help you simple circuit. There is nothing difficult here, it is important to connect all the pipes correctly. When using a water heater, it is highly recommended to carry out and connect the ground. Electric current and water is a rather dangerous combination. At a minimum, an RCD must be used. The use of RCDs for storage water heater is highly desirable, especially in the country, as it will avoid shock electric shock, reduce electrical corrosion and show a malfunction of the water heater by more frequent tripping of the RCD. RCD may be rated RCD 16A 10mA or RCD 16A 30mA or with a high operating current, depending on the capacity of the water heater.

Tips for choosing the type and type of electric water heater will help you decide when buying a new device for heating water.

The safety valve is included with the water heater. If, for some reason, it was not in place, then it is worth purchasing this necessary element separately. Safety valve using tow or fum tape should be wound onto the blue exit. Above it is necessary to install an emergency shut-off valve.

The same must be done with hot water, but without safety relief valve. Turn off the hot water tap on the central riser. If you don't have a tap or counter check valve, and the tap will be open to supply hot water to the apartment, while there will be no hot water in the whole house, all hot water from your boiler will flow through the pipes to the neighbors in the riser. You can generally turn off the hot water supply tap and not use it if you plan to use the boiler all the time.

The main malfunctions of the electric boiler

The most common problem is a tank leak. This is mainly due to corrosion of the inner surface. To prevent its occurrence, manufacturers install magnesium anodes in their units to protect the metal from corrosion. However, these devices are also short-lived. Therefore, timely replacement of the anode is very important - this significantly extends the life of the boiler. Sometimes there is a leak under the gasket at the inlet or outlet pipe connections. Then you are lucky and it is quite easy to "treat". If there is a leak in the tank itself, then this is the worst malfunction, which is almost impossible to fix on your own. All attempts to brew and the like are just a waste of time and nerves. In this case (if the warranty is over) - there is only one way out - buying a new one. Here it is necessary to approach more responsibly the choice of the material from which the inner tank is made, as well as not to skip maintenance (replacement of the anode) in the future.

Faults that you can identify and fix yourself:

1. If cold water flows instead of hot, then, most likely, the problem lies in the malfunction of the heating element. In some cases, these symptoms can be caused by a poor electrical connection between the thermostat and the heating element, or by problems with the power supply in general. It is also possible that the heating element itself may fail.

The water in the included boiler does not heat up.

When the tank is connected to the network, the ouzo instantly works, this indicates a short circuit.

Replacing the heating element of the water heater, even serviceable, should be carried out at least once every five years. The water we use is not best quality, so scale appears on it very often. Even if you regularly clean it off the heating element, it still falls to the bottom of the tank. Sediment can be determined by the presence characteristic sounds, screening when heating the liquid, as well as the presence of the smell of sulfur. With frequent cleaning of the heating element from scale, it can begin to “open”, while the water will beat with current or a short circuit will simply occur.

Disconnect the water heater from the electrical network and water supply, then completely drain the water from the tank. Remove the cover (panel) blocking access to the heating element. Measure the resistance with a multimeter, if the heating element is whole, then the device will show low resistance, if there is a break, then the resistance tends to infinity.

To do this, the tester probes are installed on the contacts of the heating element. When the probes touch the heating element, the resistance value is displayed on the multimeter, for example, 0.68 or 0.37. If a unit appears on the left of the display, this means that a spiral break has occurred in the heating element.

Immediately check for "case leakage". One multimeter probe is connected to copper tube, and the other should touch one of the contacts (pins) of the heating element. If it is faulty, the device will show the minimum (with a minus) or vice versa a huge value. In the event that there is no “leakage to the body” in the heating element and it is in good condition, the tester will show the so-called break, for example, the number 1.

It should be remembered that even a heating element that works at first glance can pierce the case, by the way, this can also be checked with the same tester. Take out the heating element. Most likely you will see the heating element in a large amount of scale, its amount depends on the hardness of the water in your area. Rinse the tank, remove all scale. Then install a new heating element in the old place, you can also replace the gasket, after which you can assemble the boiler in the reverse order. Before turning on a new heating element for the first time, it is necessary to fill the tank with water, otherwise the heating element may be burned. Before collapsible, write down the connection of all electrical contacts and wires - then it will be easier to connect them correctly back.

2. If too hot water is supplied, then this symptom indicates the failure of the thermostat.

Thermostats are designed to maintain the desired temperature of the water in the tank, as well as to emergency shutdown The heating element, like all electrical parts, has its own service life, which means that at some point they need to be replaced. As a rule, the thermostat is installed on the heating element itself or next to it, does not touch the water, which means that its replacement does not require draining the water, and in general it is a much simpler procedure than replacing the heating element. You just need to remove the panel from the boiler, disconnect all the wires from the thermostat and replace it with a new one, it is very important to connect all the wires in their places. It should be remembered that all work should be carried out using similar original thermostats on tanks disconnected from the electrical network.

3. If the on and off cycles are very frequent, this may indicate that a a large number of scale. If such signs appear immediately after the purchase of the device, then a heating element is installed in it, which does not correspond to the capacity of the tank.

The "enemies" of the heating element are the impurities contained in the water, which stick to its surface in the form of scale. Scale changes the heat transfer from the heater surface to the water. As a result, firstly, the time of heating water and, accordingly, the consumption of electricity increases. And secondly, there is insufficient heat removal from the surface of the heating element: its temperature is higher than the normal operating temperature. This will damage the water heater.

4. magnesium anode- this is a tube that is installed inside the boiler and protects it inner surface from corrosion, located next to the heating element. Magnesium is more reactive than iron, so it reacts with oxygen faster. Thus, the anode, destroying itself, protects the walls of the water heater. If the anode is not replaced in time, it will completely collapse and the walls of the water heater will begin to corrode. It requires periodic replacement, if it is carried out regularly, your boiler will last much longer.

About repair instantaneous water heaters the principle of operation of this household equipment was given, so that it would be easier for a novice master to understand the essence of the problems that arise.

In this continuation of the article, the protection elements will be discussed in more detail and an algorithm for troubleshooting in instantaneous water heaters will be given.

There will also be shown videos recorded by home craftsmen in the process of repairing their flow heaters water.

Thermal protection in instantaneous water heater

If the flow sensor is damaged and stuck in the on position, then when the tap is closed, the water in this small heating zone is very overheats quickly which could damage the heater itself due to the increase in pressure. Also, due to the lack of cooling, the heating elements will overheat. To prevent this from happening, instantaneous water heaters must have temperature control sensors.

Water flow sensor for KISPEL water heater

In the model considered in the previous article, the sensors T1 and T2 are made in the form of one element, although their purpose is different. The temperature sensor T1 is set to operate when the temperature exceeds 60ºС, it interrupts the circuit. After cooling, T1 returns to the working on position again. Exceeding the temperature in this case is possible for a number of reasons not related to a breakdown in the water heater.

Thermal sensors T1 and T2 are combined in one device, indicated as an overheating sensor

Thermal sensors T1 and T2 are combined in one device, indicated as an overheating sensor The temperature sensor T2 is set to a temperature of 90ºС - one might say - this is the extreme line of protection. It will work in the event of a breakdown of the flow sensor and temperature sensor T1. Such a breakdown will not be eliminated by itself, so this protective device after operation it is necessary enable manually after the repair of the water heater. For water heaters with a digital interface, breakdowns or incorrect sensor readings will be displayed as a flashing error code on the display. An example of eliminating one of the errors is shown in the video below, which also talks about the function of thermal fuses and about repairing the electronic unit of one of the Termex water heater models:

Varieties of instantaneous water heater control systems

Depending on the model and design of the water heater, the control system for its operation can be implemented in different ways. For example, in the THERMEX STREAM model, temperature control is carried out by controlling the water flow. Myself flow adjustable special nozzles for the shower or washbasin included in the delivery. In this case, the protection components are a pressure switch and a thermal fuse (temperature sensor).

Disassembled THERMEX STREAM flow heater

Disassembled THERMEX STREAM flow heater Accordingly, electrical circuit diagram of this water heater differs significantly from the wiring diagram above - here the phase current passes in series through the pressure switch and the thermal fuse, which returns to the on position after the temperature drops. Before self-repair water heater, be sure to study the electrical diagram and instructions from the manufacturer.

An example of the THERMEX STREAM instantaneous water heater circuit

An example of the THERMEX STREAM instantaneous water heater circuit As can be seen from the comparison of two circuits from the same manufacturer, the principle of control and protection in these models of water heaters differs significantly. Water heaters have a completely different design, respectively, and the circuit will be different. Below, for example, the electrical circuit of the Atmor water heater is shown.

Scheme of instantaneous water heater ATMOR, power 7 kW

Scheme of instantaneous water heater ATMOR, power 7 kW Also, some models may have an electronic interface directly connected to the power control relays for heating the heating elements. This means that a breakdown in this electronic board, or algorithm failure may cause the water heater to stop working. Some instantaneous water heaters may have temperature control, which is achieved by switching heating elements, or using an electronic circuit.

Troubleshooting algorithm for instantaneous water heater

Above, as an example, several electrical circuits of instantaneous water heaters are given, where common components are heating elements and protective sensors. A careful study of the design and layout of an existing faulty water heater will help you understand the principle of operation and build a troubleshooting algorithm for yourself. It will also be very helpful information from masters who carried out such repairs, therefore, you need to look for information on the forums and be patient, waiting for an answer to your question. You can also find a helpful repair video.

Unfortunately, it is not always possible to find an exact guide to action when repairing an instantaneous water heater with your own hands in each case. Therefore, one has to follow own experience and generally accepted approaches to solving this problem. Any repairs must be made with minimal cost forces, energy and means, and what is important - the nerves of the master. Therefore, first of all, you should check if there is a breakdown that blocks the operation of the equipment somewhere outside its case.

A showerhead clogged with lime that caused a water heater to malfunction can be cleaned with a plastic bag of vinegar.

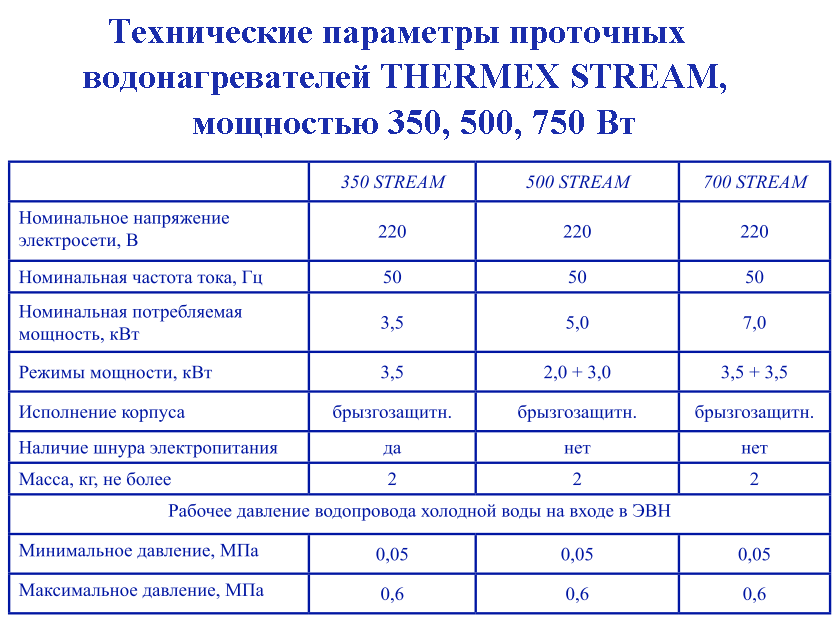

A showerhead clogged with lime that caused a water heater to malfunction can be cleaned with a plastic bag of vinegar. For example, as mentioned above, pressure (water flow) is often controlled by spout nozzles, which can become clogged due to sediment deposits. poor quality water. Often the solution to a problem with an instantaneous water heater can be to clean the hose or nozzle, as well as bring the inlet pressure of the water supply to normal parameters. Indeed, if the inlet pressure is below 0.05 MPa, then the sensors will not allow the heating elements to turn on. The same can be said about the correspondence of electrical parameters, which are also shown in the table below.

Operating parameters of instantaneous water heaters Termex Stream

Operating parameters of instantaneous water heaters Termex Stream Repair of electrical components of instantaneous water heater

If the failure of the instantaneous water heater is accompanied by the operation of the RCD that protects this power line, then the breakdown is obvious - a breakdown of the heating element on the body. In this case, a great success for the master will be a short circuit to the body in some other node - for example, a wire that has fallen off (burned out) from the terminal. To check the heating element for breakdown, switch the multimeter to the megohm measurement mode - ideal resistance - infinity. Considering the conditions of use of a water heater that are critical for human health, the leakage resistance in the heating element below Megaohm can be potentially dangerous.

Even without disassembling the water heater, it is possible to carry out its preliminary diagnostics by changing the operation of the equipment, paying attention to noise and light indication

For example, you can check the health of the flow control system by clicking on the power relays for turning on the heating element. In this case, there is often burnout of the terminals and poor contact on them, or failure of the heating elements themselves. If you have a tester or even a homemade probe, it will not be difficult to ring the active coil of the heating element. The dialing of various conductors has been discussed many times on other pages of this resource. Depending on the power of the heating element, its resistance will be within units - tens of ohms.

Continuity of the heating element of the water heater

Continuity of the heating element of the water heater After making sure that the heating element is working and checking the reliability of the contacts, you should test the relay itself - the operation of its magnetic system and a click do not guarantee the serviceability of this unit. Contact pads inside the relay are subject to burnout and wear. Therefore, you should ring the pairs of contacts of the power relay. If a lack of conduction is detected in a closed pair of contacts, the relay must be replaced.

Instantaneous water heater power relay

Instantaneous water heater power relay Many craftsmen successfully disassemble even non-separable relay designs if a replacement cannot be found. Here is a repair tip - to learn as much as possible about the design of this relay, the sequence and the possibility of disassembling it in order to get to the switching contacts in order to be able to clean them, bend, fix - in a word - eliminate the problem of the missing contact.

Water flows - but does not heat up with a working relay and heating elements - which means that the fluid flow sensor itself is faulty. As mentioned above, you can check the water flow sensor with a powerful magnet by bringing it close to this component. If the suspicion is confirmed, the faulty sensor must be replaced.

Water flow sensor, often used in various models of instantaneous water heaters

Water flow sensor, often used in various models of instantaneous water heaters The serviceability of thermal fuses and pressure sensors (pressure switches), if the pressure parameters correspond, can be checked by checking them with a tester. By temporarily shunting their outputs with a wire, you can make sure that the problem was precisely in them. The shunt should never be left to work on a permanent basis - because in this case the equipment will be deprived of protection, which can lead to very disastrous consequences - faulty protective components must be replaced.

Breakdowns of instantaneous water heaters due to the fault of the manufacturer

Many owners of instantaneous water heaters complain about the poor assembly of their products. The most common problem is the mismatch of the wires and terminals with the load currents flowing in them. Very often, unscrupulous manufacturers of instantaneous water heaters install cheap and low-quality components, as well as save on wires and terminals.

Burnt and melted terminals cause loss of contact

Burnt and melted terminals cause loss of contact If, before the breakdown, during the operation of the instantaneous water heater, a characteristic smell of insulation melting was noticed, then the cause of the malfunction may well be loss of contact or even burning out too thin wire. Replacing the contact terminals and wires with better and more reliable substitutes can eliminate this problem.

To save yourself from such breakdowns in the future, you should choose equipment only from trusted manufacturers. You should also explore the possibility of disassembling the equipment before buying, because some compact models instantaneous water heaters have a non-separable body design, which is almost impossible to disassemble without spoiling the appearance and functionality of the device itself.