How a hovercraft works. Hovercraft (Hovercraft)

In Russia, there are entire communities of people who collect and develop amateur hovercraft. This is a very interesting, but, unfortunately, difficult and far from cheap activity.

KVP body manufacturing

It is known that hovercraft experience much less stress than conventional planing boats and boats. The entire load is taken by a flexible fence. Kinetic energy when moving, it is not transmitted to the body and this circumstance makes possible mounting any hull, without complex strength calculations. The only limitation for the amateur STOL hull is weight. This must be taken into account when performing theoretical drawings.

Another important aspect is the degree of resistance to the oncoming air flow. After all, aerodynamic characteristics directly affect fuel consumption, which, even for amateur SVPs, is comparable to the consumption of an average SUV. Professional aerodynamic design worth big money, so amateur designers do everything "by eye", simply borrowing lines and shapes from the leaders of the automotive industry or aviation. About copyright in this case, you can not think.

For the manufacture of the hull of the future boat, you can use spruce slats. As a sheathing - plywood 4 mm thick, which is attached with epoxy glue. Pasting plywood with a dense fabric (for example, fiberglass) is impractical due to a significant increase in the weight of the structure. This is the most technologically uncomplicated way.

The most sophisticated members of the community create fiberglass enclosures from their own computer 3d models or by eye. To begin with, a prototype is created and a material such as foam plastic is removed from which the matrix is removed. Further, the hulls are made in the same way as fiberglass boats and boats.

The unsinkability of the hull can be achieved in many ways. For example, by installing water-tight partitions in the side compartments. Better yet, you can fill these compartments with foam. You can install inflatable balloons under the flexible fence, similar to PVC boats.

SVP power plant

The main question is how much, and he meets the designer all the way through the design of the power system. How many engines, how much the frame and engine should weigh, how many fans, how many blades, how many revolutions, how many degrees to make the angle of attack and in the end how much it will cost. It is this stage that is the most costly, because in artisanal conditions it is impossible to build an internal combustion engine or a fan blade with the desired efficiency and noise level. You have to buy such things, and they are not cheap.

The most difficult stage of the assembly was the installation of a flexible fence of the boat, which holds the air cushion exactly under the hull. It is known that due to constant contact with rough terrain, it is prone to rapid wear. Therefore, canvas fabric was used to create it. The complex configuration of the fence joints required the consumption of such fabric in the amount of 14 meters. Its wear resistance can be increased by impregnation with rubber adhesive with the addition of aluminum powder. This coverage has a huge practical value. In case of wear or tear of the flexible fence, it can be easily restored. By analogy with building up a car tread. According to the author of the project, before you start making a fence, you should stock up on maximum patience.

Installation finished fence, as well as the assembly of the hull itself, must be carried out provided that the future boat is keel up. After raskantovy case, you can install the power plant. For this operation, you will need a mine with dimensions of 800 by 800. After the control system is connected to the engine, the most exciting moment in the whole process comes - testing the boat in real conditions.

Quality road network in our country leaves much to be desired. Construction in some directions is impractical for economic reasons. With the movement of people and goods in such areas, vehicles operating on other physical principles will do just fine. Do-it-yourself full-sized ships in artisanal conditions cannot be built, but scale models- quite possible.

Vehicles of this type are capable of moving on any relatively flat surface. It can be an open field, a pond, and even a swamp. It is worth noting that on such surfaces unsuitable for other vehicles, the SVP is able to develop a fairly high speed. The main disadvantage of such transport is the need for large energy costs to create an air cushion and, as a result, high fuel consumption.

Physical principles of operation of the SVP

The high permeability of vehicles of this type is ensured by the low specific pressure that it exerts on the surface. This is explained quite simply: the contact area of the vehicle is equal to or even exceeds the area of the vehicle itself. In encyclopedic dictionaries, SVPs are defined as vessels with a dynamically generated reference thrust.

Large and hovercraft hover above the surface at a height of 100 to 150 mm. Air is created in a special device under the body. The machine breaks away from the support and loses mechanical contact with it, as a result of which the movement resistance becomes minimal. The main energy costs are spent on maintaining the air cushion and accelerating the apparatus in a horizontal plane.

Drafting a project: choosing a working scheme

For the manufacture of an operating model of the SVP, it is necessary to choose an effective hull design for the given conditions. Drawings of hovercraft can be found on specialized resources where patents are posted with a detailed description different schemes and ways to implement them. Practice shows that one of the most good options for media such as water and solid ground, the chamber method of forming an air cushion is.

In our model, a classic two-engine scheme with one pumping power drive and one pusher will be implemented. Small-sized do-it-yourself hovercraft made, in fact, are toys-copies of large devices. However, they clearly demonstrate the advantages of using such vehicles over others.

Ship hull manufacturing

When choosing a material for the ship's hull, the main criteria are ease of processing and low hovercraft are classified as amphibious, which means that in the event of an unauthorized stop, flooding will not occur. The ship's hull is sawn out of plywood (4 mm thick) according to a pre-prepared template. To perform this operation, a jigsaw is used.

A homemade hovercraft has superstructures that are best made from Styrofoam to reduce weight. To give them a greater external resemblance to the original, the parts are glued on the outside with foam plastic and painted. Cabin windows are made of transparent plastic, and the rest of the parts are cut from polymers and bent from wire. Maximum detail is the key to similarity with the prototype.

Air chamber dressing

In the manufacture of the skirt, a dense fabric made of polymeric waterproof fiber is used. Cutting is carried out according to the drawing. If you do not have experience transferring sketches to paper manually, then they can be printed on a large-format printer on thick paper, and then cut out with ordinary scissors. The prepared parts are sewn together, the seams should be double and tight.

Do-it-yourself hovercraft, before turning on the injection engine, rest on the ground with their hull. The skirt is partially rumpled and is located under it. The parts are glued with waterproof glue, the joint is closed by the body of the superstructure. This connection provides high reliability and allows you to make mounting joints invisible. Other external parts are also made of polymeric materials: a propeller diffuser guard and the like.

Power point

As part of the power plant there are two engines: forcing and sustainer. The model uses brushless electric motors and two-bladed propellers. Remote control of them is carried out using a special regulator. The power source for the power plant are two batteries with a total capacity of 3000 mAh. Their charge is enough for half an hour of using the model.

Homemade hovercraft are controlled remotely via radio. All components of the system - radio transmitter, receiver, servos - are prefabricated. Installation, connection and testing of them is carried out in accordance with the instructions. After the power is turned on, a test run of the motors is performed with a gradual increase in power until a stable air cushion is formed.

SVP Model Management

Hovercraft, made by hand, as noted above, have remote control via the VHF channel. In practice it looks like in the following way: The owner is holding a radio transmitter. The engines are started by pressing the corresponding button. Joystick controls the speed and direction of movement. The machine is easy to maneuver and quite accurately maintains the course.

Tests have shown that the SVP confidently moves on a relatively flat surface: on water and on land with equal ease. The toy will become a favorite entertainment for a child aged 7-8 years old with a fairly developed fine motor skills fingers.

Once in winter, when I, walking along the banks of the Daugava, looked at the snow-covered boats, I had an idea - create an all-weather vehicle, i.e. amphibian, which could be used in winter.

Once in winter, when I, walking along the banks of the Daugava, looked at the snow-covered boats, I had an idea - create an all-weather vehicle, i.e. amphibian, which could be used in winter.

After much deliberation, my choice fell on a double air cushion device. At first, I had nothing but a great desire to create such a design. The technical literature available to me summarized the experience of creating only large SVPs, and I could not find any data on small devices for walking and sports purposes, especially since such SVPs are not produced by our industry. So, one could only hope for own forces and experience (my amphibious boat based on the Yantar motorboat was once reported in KYA; see No. 61).

Anticipating that in the future I might find followers, and with positive results, the industry might also be interested in my apparatus, I decided to design it on the basis of well-developed and commercially available two-stroke engines.

Anticipating that in the future I might find followers, and with positive results, the industry might also be interested in my apparatus, I decided to design it on the basis of well-developed and commercially available two-stroke engines.

In principle, the hovercraft experiences significantly less stress than the traditional planing hull of the boat; this allows the design to be made lighter. At the same time, an additional requirement appears: the body of the apparatus must have low aerodynamic resistance. This must be taken into account when developing a theoretical drawing.

| Basic data of amphibious hovercraft | |

|---|---|

| Length, m | 3,70 |

| Width, m | 1,80 |

| Board height, m | 0,60 |

| Air cushion height, m | 0,30 |

| Power of lifting installation, l. with. | 12 |

| Traction power, l. with. | 25 |

| Payload capacity, kg | 150 |

| Total weight, kg | 120 |

| Speed, km/h | 60 |

| Fuel consumption, l/h | 15 |

| Fuel tank capacity, l | 30 |

1 - steering wheel; 2- dashboard; 3 - longitudinal seat; 4 - lifting fan; 5 - fan casing; 6 - draft fans; 7 - fan shaft pulley; 8 - engine pulley; 9 - traction engine; 10 - silencer; 11 - control flaps; 12 - fan shaft; 13 - fan shaft bearings; 14 - windshield; 15 - flexible fence; 16 - draft fan; 17 - casing of the traction fan; 18 - lifting engine; 19 - muffler lifting engine;

20 - electric starter; 21 - battery; 22 - fuel tank.

I made a set of body from spruce slats with a section of 50x30 and sheathed with 4 mm plywood on epoxy glue. I didn't do fiberglass pasting, fearing an increase in the weight of the device. To ensure unsinkability, I installed two watertight bulkheads in each of the onboard compartments, and also filled the compartments with foam.

A twin-engine scheme of the power plant was chosen, i.e. one of the engines works to lift the apparatus, creating excess pressure (air cushion) under its bottom, and the second provides movement - creates horizontal thrust. The lifting engine, based on the calculation, should have had a power of 10-15 liters. with. According to the basic data, the engine from the Tula-200 scooter turned out to be the most suitable, but since neither the mounts nor the bearings satisfied it for structural reasons, a new crankcase had to be cast from an aluminum alloy. This motor drives a 6-blade 600 mm fan. The total weight of the lifting power plant, together with the mounts and the electric starter, turned out to be about 30 kg.

One of the most difficult stages was the manufacture of a skirt - a flexible pillow guard, which wears out quickly during operation. A commercially available canvas fabric 0.75 m wide was used. Due to the complex configuration of the joints, about 14 m of such fabric was required. The strip was cut into pieces with a length equal to the length of the bead, with an allowance for a rather complex shape of the joints. After giving the required shape, the joints were sewn together. The edges of the fabric were fastened to the body of the apparatus with duralumin strips 2x20. To increase wear resistance, I impregnated the installed flexible fence with rubber glue, to which I added aluminum powder, which gives an elegant look. This technology makes it possible to restore a flexible fence in case of an accident and as it wears out, similar to tread build-up. car tire. It should be emphasized that the manufacture of a flexible fence is not only time-consuming, but requires special care and patience.

The assembly of the hull and the installation of a flexible fence were carried out in the keel up position. Then the hull was rolled up and a lifting power plant was installed in a shaft measuring 800x800. The installation control system was summed up, and now the most crucial moment has come; her testing. Will the calculations come true, will such a device be lifted by a relatively low-power engine?

Already at medium engine speeds, the amphibian rose with me and hovered at a height of about 30 cm from the ground. The reserve of lifting power turned out to be quite enough for a warm engine to lift even four people at full speed. In the very first minutes of these tests, the features of the apparatus began to emerge. After proper centering, he freely moved on an air cushion in any direction, even with a small applied effort. It looked like he was floating on the surface of the water.

The success of the first test of the lifting unit and the hull as a whole inspired me. Having secured the windshield, I proceeded to install the traction power plant. At first it seemed expedient to take advantage of the great experience in the construction and operation of snowmobiles and install an engine with a propeller of a relatively large diameter on the aft deck. However, it should be taken into account that with such a “classic” version, the center of gravity of such a small apparatus would have increased significantly, which would inevitably have an effect on its driving performance and, most importantly, on safety. Therefore, I decided to use two traction engines, completely similar to the lifting one, and installed them in the aft part of the amphibian, but not on the deck, but along the sides. After I fabricated and assembled a motorcycle-type control gear and installed relatively small diameter traction propellers (“fans”), the first version of the hovercraft was ready for sea trials.

A special trailer was made for transporting the amphibian behind the Zhiguli car, and in the summer of 1978 I loaded my apparatus onto it and delivered it to a meadow near a lake near Riga. An exciting moment has come. Surrounded by friends and curious, I took the driver's seat, started the lift engine, and my new boat hovered over the meadow. Started both traction motors. With an increase in the number of their revolutions, the amphibian began to move across the meadow. And then it became clear that many years of experience in driving a car and a motorboat is clearly not enough. All previous skills are useless. It is necessary to master the methods of controlling the hovercraft, which can circle endlessly in one place, like a spinning top. As the speed increased, so did the turning radius. Any surface irregularities caused the apparatus to rotate.

Having mastered the controls, I directed the amphibian along the gently sloping shore to the surface of the lake. Once above the water, the device immediately began to lose speed. The traction motors began to stall one by one, flooded with spray escaping from under the flexible air cushion guard. When passing overgrown areas of the lake, the fans drew in the reeds, the edges of their blades crumbled. When I turned off the engines, and then decided to try to take a start from the water, nothing happened: my device could not escape from the "pit" formed by the pillow.

All in all, it was a failure. However, the first defeat did not stop me. I came to the conclusion that when existing characteristics for my hovercraft, the power of the traction unit is insufficient; that is why he could not move forward when starting from the surface of the lake.

During the winter of 1979, I completely redesigned the amphibian, reducing its hull length to 3.70 m and its width to 1.80 m. I also designed a completely new traction unit, completely protected from splashes and from contact with grass and reeds. To simplify the control of the installation and reduce its weight, one traction motor was used instead of two. Used power head 25-horsepower outboard motor"Vikhr-M" with a completely redone cooling system. closed system cooling with a volume of 1.5 liters is filled with antifreeze. The engine torque is transmitted to the “propeller” fan shaft located across the apparatus using two V-belts. Six-bladed fans force air into the chamber, from which it escapes (along the way cooling the engine) aft through a square nozzle equipped with control flaps. From an aerodynamic point of view, such a propulsion system, apparently, is not very perfect, but it is quite reliable, compact and creates a thrust of about 30 kgf, which turned out to be quite sufficient.

During the winter of 1979, I completely redesigned the amphibian, reducing its hull length to 3.70 m and its width to 1.80 m. I also designed a completely new traction unit, completely protected from splashes and from contact with grass and reeds. To simplify the control of the installation and reduce its weight, one traction motor was used instead of two. Used power head 25-horsepower outboard motor"Vikhr-M" with a completely redone cooling system. closed system cooling with a volume of 1.5 liters is filled with antifreeze. The engine torque is transmitted to the “propeller” fan shaft located across the apparatus using two V-belts. Six-bladed fans force air into the chamber, from which it escapes (along the way cooling the engine) aft through a square nozzle equipped with control flaps. From an aerodynamic point of view, such a propulsion system, apparently, is not very perfect, but it is quite reliable, compact and creates a thrust of about 30 kgf, which turned out to be quite sufficient.

In the middle of the summer of 1979, my apparatus was again transported to the same meadow. Having mastered the controls, I directed him to the lake. This time, once above the water, he continued to move without losing speed, as if on the surface of ice. Easily, without interference, overcame shallows and reeds; it was especially pleasant to move over the overgrown areas of the lake, there was not even a foggy trail here. On the straight section, one of the owners with the Whirlwind-M engine went in a parallel course, but soon fell behind.

The described apparatus was of particular surprise to fans of ice fishing when I continued testing the amphibian in winter on ice, which was covered with a layer of snow about 30 cm thick. There was a real expanse on the ice! The speed could be increased to the maximum. I didn’t measure it exactly, but the driver’s experience suggests that it was approaching 100 km / h. At the same time, the amphibian freely overcame deep traces from motonart.

A small film was filmed and shown by the Riga TV studio, after which I began to receive many requests from those who wanted to build a similar amphibious vehicle.

The high speed characteristics and amphibious capabilities of hovercraft (AHVs), as well as the relative simplicity of their designs, attract the attention of amateur designers. In recent years, many small WUAs have appeared, built independently and used for sports, tourism or business trips.

In some countries, for example, in Great Britain, the USA and Canada, mass industrial production of small WUAs has been established; ready-made devices or sets of parts for self-assembly are offered.

A typical sports WUA is compact, simple in design, has independent lifting and propulsion systems, and easily moves both above ground and above water. These are predominantly single-seat vehicles with carburetor motorcycle or light air-cooled automobile engines.

Tourist WUAs are more complex in design. Usually they are two- or four-seater, designed for relatively long trips and, accordingly, have trunks, fuel tanks large capacity, devices to protect passengers from the weather.

For economic purposes, small platforms are used, adapted to transport mainly agricultural goods over rough and swampy terrain.

Main characteristics

Amateur WUAs are characterized by the main dimensions, weight, diameter of the supercharger and propeller, distance from the center of mass of the WUA to the center of its aerodynamic drag.In table. 1 compares the most important technical data of the most popular English amateur WUAs. The table allows you to navigate in a wide range of values of individual parameters and use them for comparative analysis with your own projects.

The lightest WUAs have a mass of about 100 kg, the heaviest - more than 1000 kg. Naturally, the smaller the mass of the apparatus, the less engine power is required for its movement or the higher performance can be achieved with the same power consumption.

Below are the most characteristic data on the mass of individual components that make up the total mass of an amateur WUA: an air-cooled carburetor engine - 20-70 kg; axial blower. (pump) - 15 kg, centrifugal pump- 20 kg; propeller - 6-8 kg; motor frame - 5-8 kg; transmission - 5-8 kg; propeller nozzle ring - 3-5 kg; controls - 5-7 kg; body - 50-80 kg; fuel tanks and gas lines - 5-8 kg; seat - 5 kg.

The total carrying capacity is determined by calculation depending on the number of passengers, the given amount of cargo carried, the fuel and oil reserves necessary to ensure the required cruising range.

In parallel with the calculation of the mass of the AWP, an accurate calculation of the position of the center of gravity is required, since the driving performance, stability and controllability of the vehicle depend on this. The main condition is that the resultant of the air cushion support forces pass through the common center of gravity (CG) of the apparatus. At the same time, it should be taken into account that all masses that change their value during operation (such as, for example, fuel, passengers, cargo) must be placed close to the CG of the device so as not to cause it to move.

The center of gravity of the apparatus is determined by calculation according to the drawing of the lateral projection of the apparatus, where the centers of gravity of individual units, structural units of passengers and cargo are applied (Fig. 1). Knowing the masses G i and the coordinates (relative to the coordinate axes) x i and y i of their centers of gravity, it is possible to determine the position of the CG of the entire apparatus by the formulas:

The designed amateur WUA must meet certain operational, design and technological requirements. The basis for the creation of a project and design of a new type of WUA are, first of all, the initial data and technical conditions that determine the type of apparatus, its purpose, gross weight, load capacity, dimensions, type of main power plant, running characteristics and specific features.

From tourist and sports WUAs, as, indeed, from other types of amateur WUAs, ease of manufacture, the use of easily accessible materials and assemblies in the design, as well as complete safety of operation are required.

Speaking about driving characteristics, they mean the height of the AWP and the ability to overcome obstacles associated with this quality, maximum speed and throttle response, as well as the length of the braking distance, stability, controllability, and cruising range.

In the WUA design, the hull shape plays a fundamental role (Fig. 2), which is a compromise between:

- a) round in terms of contours, which are characterized the best parameters air cushion at the time of hovering in place;

- b) drop-shaped contours, which is preferable from the point of view of reducing aerodynamic drag during movement;

- c) a pointed nose ("beak-shaped") hull shape, optimal from a hydrodynamic point of view during movement on a rough water surface;

- d) the form that is optimal for operational purposes.

Using statistics on existing structures, which correspond to the newly created WUA type, the constructor must set:

- weight of apparatus G, kg;

- air cushion area S, m 2 ;

- length, width and outline of the hull in plan;

- lifting system engine power N v.p. , kW;

- traction motor power N dv, KW.

- pressure in the air cushion P v.p. =G:S;

- specific power of the lifting system q v.p. = G:N c.p. .

- specific power of the traction motor q dv = G:N dv, and also start developing the configuration of the AWP.

The principle of creating an air cushion, superchargers

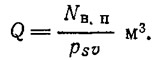

Most often, in the construction of amateur WUAs, two schemes for the formation of an air cushion are used: chamber and nozzle.In the chamber circuit, which is most often used in simple designs, the volume flow of air passing through the air path of the apparatus is equal to the volume flow of air of the blower

![]()

where:

F is the area of the perimeter of the gap between the support surface and the lower edge of the apparatus body, through which air exits from under the apparatus, m 2 ; it can be defined as the product of the perimeter of the air cushion fence P and the gap h e between the fence and the supporting surface; usually h 2 = 0.7÷0.8h, where h is the hovering height of the apparatus, m;

υ - speed of air outflow from under the device; with sufficient accuracy, it can be calculated by the formula:

where P c.p. - air cushion pressure, Pa; g - free fall acceleration, m/s 2 ; y - air density, kg / m 3.

The power required to create an air cushion in a chamber circuit is determined by the approximate formula:

where P c.p. - pressure after the supercharger (in the receiver), Pa; η n - the efficiency of the supercharger.

Air cushion pressure and air flow are the main parameters of an air cushion. Their values depend primarily on the dimensions of the apparatus, i.e., on the mass and bearing surface, on the hovering height, speed of movement, the method of creating an air cushion and resistance in the air path.

The most economical air-cushion vehicles are large-sized or large bearing surfaces for which the minimum pressure in the cushion allows a sufficiently large load capacity to be obtained. However, independent construction of a large-sized apparatus is associated with difficulties in transportation and storage, and is also limited by the financial capabilities of an amateur designer. With a decrease in the size of the WUA, a significant increase in air cushion pressure is required and, accordingly, an increase in power consumption.

In turn, negative phenomena depend on the pressure in the air cushion and the rate of air flow from under the apparatus: splashing while moving over water and dusting when moving over a sandy surface or loose snow.

Apparently, the successful design of the WUA is, in a certain sense, a compromise between the contradictory dependencies described above.

To reduce the power consumption for the passage of air through the air channel from the supercharger into the cavity of the pillow, it must have a minimum aerodynamic resistance (Fig. 3). The power losses that are inevitable during the passage of air through the channels of the air path are of two kinds: the loss due to the movement of air in straight channels of constant cross section and local losses due to the expansion and bending of the channels.

In the air path of small amateur WUAs, losses due to the movement of air flows along straight channels of constant cross section are relatively small due to the insignificant length of these channels, as well as the thoroughness of their surface treatment. These losses can be estimated using the formula:

where: λ is the coefficient of pressure loss per channel length, calculated according to the graph shown in fig. 4, depending on the Reynolds number Re=(υ d): v, υ - air velocity in the channel, m/s; l - channel length, m; d - channel diameter, m (if the channel has a different round section, then d is the diameter of a cylindrical channel equivalent in cross-sectional area); v - coefficient of kinematic viscosity of air, m 2 / s.

Local power losses associated with a strong increase or decrease in the cross section of the channels and significant changes in the direction of the air flow, as well as losses for air intake into the supercharger, nozzles and rudders, are the main costs of the supercharger power.

Here ζ m is the coefficient of local losses, depending on the Reynolds number, which is determined by the geometric parameters of the source of losses and the speed of air passage (Fig. 5-8).

The supercharger in the AUA must create a certain air pressure in the air cushion, taking into account the power consumption to overcome the resistance of the channels to the air flow. In some cases, part air flow it is also used to form a horizontal thrust of the apparatus in order to ensure movement.

The total pressure generated by the supercharger is the sum of the static and dynamic pressures:

![]()

Depending on the type of WUA, the area of the air cushion, the height of the apparatus and the magnitude of the losses, the constituent components p sυ and p dυ vary. This determines the choice of type and performance of superchargers.

In the chamber scheme of the air cushion static pressure p sυ , necessary to create lift, can be equated to the static pressure behind the supercharger, the power of which is determined by the formula above.

When calculating the required power of an AVP blower with a flexible air cushion guard (nozzle circuit), the static pressure downstream of the blower can be calculated using the approximate formula:

where: R v.p. - pressure in the air cushion under the bottom of the apparatus, kg/m 2 ; kp - pressure drop coefficient between the air cushion and the channels (receiver), equal to k p = P p: P v.p. (P p - pressure in the air channels behind the supercharger). The value of k p ranges from 1.25÷1.5.

The blower air volume flow can be calculated using the formula:

The regulation of the performance (flow rate) of the AVP blowers is most often carried out - by changing the rotational speed or (less often) by throttling the air flow in the channels with the help of rotary dampers located in them.

After the required power of the supercharger is calculated, it is necessary to find an engine for it; most often, hobbyists use motorcycle engines if power up to 22 kW is required. At the same time, as rated power accepted 0.7-0.8 maximum power engine specified in the motorcycle passport. It is necessary to provide for intensive cooling of the engine and thorough cleaning of the air entering through the carburetor. It is also important to obtain a unit with a minimum mass, which is the sum of the mass of the engine, the transmission between the supercharger and the engine, as well as the mass of the supercharger itself.

Depending on the type of WUA, engines with a displacement of 50 to 750 cm 3 are used.

In amateur WUAs, both axial superchargers and centrifugal superchargers are used equally. Axial superchargers are intended for small and simple structures, centrifugal - for AVP with significant pressure in the air cushion.

Axial superchargers typically have four or more vanes (Figure 9). They are usually made of wood (four-blade) or metal (superchargers with large quantity blades). If they are made of aluminum alloys, then the rotors can be cast, and welding can also be applied; it is possible to make them of welded structure from steel sheet. The range of pressure generated by axial four-blade superchargers is 600-800 Pa (about 1000 Pa with a large number of blades); The efficiency of these superchargers reaches 90%.

Centrifugal blowers are made of a welded metal structure or molded from fiberglass. The blades are made bent from a thin sheet or with a profiled cross section. Centrifugal superchargers create pressure up to 3000 Pa, and their efficiency reaches 83%.

Choice of traction complex

Propulsors that create horizontal thrust can be divided mainly into three types: air, water and wheeled (Fig. 10).An air propulsor is understood to mean an aircraft-type propeller with or without a ring-nozzle, an axial or centrifugal supercharger, as well as an air-jet propulsion. In the simplest designs, horizontal thrust can sometimes be created by tilting the AWP and using the resulting horizontal component of the force of the air flow flowing from the air cushion. The air mover is convenient for amphibious vehicles that do not have contact with the supporting surface.

If we are talking about WUAs that move only above the surface of the water, then you can use a propeller or a water jet propulsion. Compared to air propulsion, these propulsion units allow you to get much more thrust per kilowatt of power expended.

The approximate value of the thrust developed by various propellers can be estimated from the data shown in Fig. eleven.

When choosing elements of a propeller, one should take into account all types of resistance that occur during the movement of the WUA. Aerodynamic drag is calculated by the formula

![]()

The water resistance due to the formation of waves when the WUA moves through the water can be calculated by the formula

where:

V - WUA movement speed, m/s; G - WUA mass, kg; L is the length of the air cushion, m; ρ - water density, kg s 2 / m 4 (at a temperature sea water+4°С equals 104, river - 102);

C x - coefficient of aerodynamic resistance, depending on the shape of the device; is determined by blowing WUA models in wind tunnels. Approximately, you can take C x =0.3÷0.5;

S - cross-sectional area of the WUA - its projection on a plane perpendicular to the direction of movement, m 2 ;

E - wave resistance coefficient, depending on the AWP speed (Froude number Fr=V:√g·L) and the ratio of air cushion dimensions L:B (Fig. 12).

As an example, in Table. 2 shows the calculation of resistance depending on the speed of movement for a device with a length of L = 2.83 m and B = 1.41 m.

Knowing the resistance to the movement of the apparatus, it is possible to calculate the engine power required to ensure its movement at a given speed (in this example 120 km / h), assuming the efficiency of the propeller η p equal to 0.6, and the efficiency of transmission from the engine to the propeller η p \u003d 0.9:

As an air propulsor for amateur WUAs, a two-blade propeller is most often used (Fig. 13).

The blank for such a screw can be glued from plywood, ash or pine plates. The edge as well as the ends of the blades, which are subjected to mechanical action of solid particles or sand sucked in together with the air flow, are protected by a fitting made of brass sheet.

Four-bladed propellers are also used. The number of blades depends on the operating conditions and the purpose of the propeller - for the development of high speed or the creation of significant thrust at the time of launch. A two-blade propeller with wide blades can also provide sufficient thrust. Thrust is generally increased if the propeller runs in a profiled nozzle ring.

The finished screw must be balanced, mainly statically, before being mounted on the motor shaft. Otherwise, it will vibrate when it rotates, which may cause damage to the entire machine. Balancing with an accuracy of 1 g is quite sufficient for amateurs. In addition to balancing the screw, its runout relative to the axis of rotation is checked.

General layout

One of the main tasks of the designer is to connect all the aggregates into one functional whole. When designing the apparatus, the designer is obliged to provide a place for the crew, placement of units of the lifting and propulsion systems within the hull. At the same time, it is important to use the designs of already known WUAs as a prototype. On fig. Figures 14 and 15 show structural diagrams of two typical amateur-built WUAs.In most WUAs, the body is a load-bearing element, a single structure. It contains the units of the main power plant, air channels, control devices and the driver's cab. The driver's cabs are located in the bow or central part of the apparatus, depending on where the supercharger is located - behind the cab or in front of it. If the WUA is multi-seat, the cabin is usually located in the middle part of the vehicle, which makes it possible to operate it with a different number of people on board without changing the alignment.

In small amateur WUAs, the driver's seat is most often open, protected in front by a windshield. In devices of a more complex design (tourist type), the cabins are covered with a transparent plastic dome. To accommodate the necessary equipment and supplies, the volumes available on the sides of the cabin and under the seats are used.

With air engines, the control of the AVP is carried out using either rudders placed in the air stream behind the propeller, or guide devices fixed in the air stream flowing from the air-jet propulsion unit. The control of the device from the driver's seat can be of an aviation type - using the handles or levers of the steering wheel, or, as in a car, the steering wheel and pedals.

In amateur WUAs, two main types of fuel systems are used; with gravity fuel supply and with an automotive or aircraft-type gasoline pump. Fuel system parts, such as valves, filters, oil system with tanks (if a four-stroke engine is used), oil coolers, filters, water cooling system (if it is a water-cooled engine), are usually selected from existing aviation or automotive parts.

Exhaust gases from the engine are always discharged to the rear of the vehicle and never to the pillow. To reduce the noise generated during the operation of WUAs, especially near settlements, automobile-type silencers are used.

In the simplest designs Bottom part The hull serves as a chassis. The role of the chassis can be performed by wooden skids (or skids), which take on the load when in contact with the surface. In tourist WUAs, which are heavier than sports WUAs, wheeled chassis are mounted, which facilitate the movement of WUAs during stops. Usually two wheels are used, mounted on the sides or along the longitudinal axis of the WUA. The wheels have contact with the surface only after the cessation of the lifting system, when the AUA touches the surface.

Materials and manufacturing technology

For the manufacture of WUA wooden structure They use high-quality pine lumber, similar to those used in the aircraft industry, as well as birch plywood, ash, beech and linden wood. For gluing wood, a waterproof glue with high physical and mechanical properties is used.For flexible fences, technical fabrics are mainly used; they must be exceptionally durable, resistant to atmospheric influences and humidity, as well as friction. In Poland, fire-resistant fabric covered with plastic-like PVC is most often used.

It is important to perform the correct cutting and ensure that the panels are carefully connected to each other, as well as fastening them to the device. To fasten the shell of the flexible fence to the body, metal strips are used, which, by means of bolts, evenly press the fabric against the body of the apparatus.

When designing the form of a flexible air cushion fence, one should not forget about Pascal's law, which states that air pressure is distributed in all directions with the same force. Therefore, the shell of the flexible barrier in the inflated state must be in the form of a cylinder or a sphere, or a combination thereof.

Housing design and strength

The forces from the cargo carried by the vehicle, the weight of the mechanisms of the power plant, etc., are transferred to the hull of the WUA, as well as the loads from external forces, impacts of the bottom on the wave and from the pressure in the air cushion. The supporting structure of the hull of an amateur WUA is most often a flat pontoon, which is supported by pressure in the air cushion, and in the swimming mode ensures the buoyancy of the hull. The hull is affected by concentrated forces, bending and torsional moments from the engines (Fig. 16), as well as gyroscopic moments from the rotating parts of the mechanisms that occur during the AWP maneuvering.The most widely used are two constructive types of buildings for amateur WUAs (or their combinations):

- truss construction, when the overall strength of the hull is ensured by flat or spatial trusses, and the skin is intended only to hold air in the air path and create buoyancy volumes;

- with load-bearing plating, when the overall strength of the hull is provided by the outer plating, working in conjunction with the longitudinal and transverse framing.

The design of the cab and its glazing should ensure the possibility of a quick exit of the driver and passengers from the cab, especially in the event of an accident or fire. The location of the windows should provide the driver good review: line of sight must be between 15° down and 45° up from horizontal line; side view must be at least 90 ° on each side.

Power transmission to propeller and supercharger

The simplest for amateur manufacturing are V-belt and chain drives. However, a chain drive is used only to drive propellers or superchargers whose rotation axes are located horizontally, and even then only if it is possible to select the appropriate motorcycle sprockets, since their manufacture is quite difficult.In the case of V-belt transmission, to ensure the durability of the belts, the diameters of the pulleys should be chosen as maximum, however, the circumferential speed of the belts should not exceed 25 m/s.

The design of the lifting complex and flexible fencing

The lifting complex consists of an injection unit, air channels, a receiver and a flexible air cushion guard (in nozzle schemes). The channels through which air is supplied from the blower to the flexible enclosure must be designed taking into account the requirements of aerodynamics and ensure minimal pressure loss.Flexible fences of amateur WUAs usually have a simplified form and design. On fig. 18 showing examples constructive schemes flexible barriers and a method for checking the shape of the flexible barrier after its installation on the apparatus body. Fences of this type have good elasticity, and due to the rounded shape they do not cling to the unevenness of the supporting surface.

The calculation of superchargers, both axial and centrifugal, is rather complicated and can only be performed using special literature.

The steering device, as a rule, consists of a steering wheel or pedals, a system of levers (or cable wiring) connected to a vertical rudder, and sometimes to a horizontal rudder - an elevator.

The control can be made in the form of an automobile or motorcycle steering wheel. Taking into account, however, the specifics of the design and operation of the WUA as an aircraft, the aviation design of the controls in the form of a lever or pedals is more often used. In its simplest form (Fig. 19), when the handle is tilted sideways, the movement is transmitted by means of a lever fixed on the pipe to the elements of the steering cable wiring and then to the rudder. The movements of the handle back and forth, possible due to its hinged fastening, are transmitted through the pusher, passing inside the tube, to the wiring of the elevator.

With pedal control, regardless of its scheme, it is necessary to provide for the possibility of moving either the seat or the pedals for adjustment in accordance with individual features driver. Levers are most often made of duralumin, transmission pipes are attached to the body with brackets. The movement of the levers is limited by openings in the cutouts in the guides mounted on the sides of the apparatus.

An example of the design of the rudder in the case of its placement in the air flow thrown by the propeller is shown in Fig. 20.

The rudders can be either fully swivel, or consist of two parts - non-swivel (stabilizer) and swivel (rudder blade) with different percentages chords of these parts. Rudder profiles of any type must be symmetrical. The rudder stabilizer is usually fixed to the body; the main bearing element of the stabilizer is the spar, to which the rudder blade is hinged. Elevators, very rare in amateur WUAs, are constructed on the same principles and sometimes even exactly the same as the rudders.

Structural elements that transmit movement from controls to steering wheels and engine throttles usually consist of levers, rods, cables, etc. With the help of rods, as a rule, forces are transmitted in both directions, while cables work only for traction. Most often, amateur WUAs use combined systems- with cables and pushers.

Editorial

Increasingly, fans of water-motor sports and tourism are paying more and more attention to hovercraft. With a relatively low power consumption, they allow you to achieve high speeds; shallow and impassable rivers are accessible to them; hovercraft can hover above the ground and above the ice.For the first time, we introduced readers to the issues of designing small SVPs back in the 4th issue (1965), placing an article by Yu. A. Budnitsky “Soaring Ships”. In was published short essay development of foreign SVPs, including a description of a number of sports and pleasure modern 1- and 2-seater SVPs. The editors introduced the experience of independent construction of such an apparatus by Riga resident O. O. Petersons in. The publication of this amateur design aroused especially great interest among our readers. Many of them wanted to build the same amphibian and asked for the necessary literature.

This year, the Sudostroenie publishing house is releasing a book by Polish engineer Jerzy Ben, Models and Amateur Hovercraft. In it you will find a presentation of the fundamentals of the theory of the formation of an air cushion and the mechanics of movement on it. The author gives the calculated ratios that are necessary for the independent design of the simplest SVP, introduces trends and development prospects of this type courts. The book contains many examples of the designs of amateur hovercraft (AHVs) built in the UK, Canada, USA, France, Poland. The book is addressed to a wide range of fans of self-construction of ships, ship modellers, water motorists. Its text is richly illustrated with drawings, drawings and photographs.

The journal publishes an abridged translation of a chapter from this book.

The four most popular foreign SVPs

American hovercraft Airskat-240

Double sports SVP with a transverse symmetrical arrangement of seats. Mechanical installation - automob. dv. "Volkswagen" with a power of 38 kW, driving an axial four-bladed supercharger and a two-bladed propeller in the ring. The control of the SVP along the course is carried out using a lever connected to a system of rudders placed in the stream behind the propeller. Electrical equipment 12 V. Engine start - electric starter. The dimensions of the device are 4.4x1.98x1.42 m. The air cushion area is 7.8 m 2; propeller diameter 1.16 m, full mass- 463 kg, maximum speed on water 64 km / h.American SVP firm "Skimmers Incorporated"

A kind of single SVP scooter. The body design is based on the idea of using a car camera. Two-cylinder motorcycle motor with a power of 4.4 kW. The dimensions of the device are 2.9x1.8x0.9 m. The air cushion area is 4.0 m 2; gross weight - 181 kg. The maximum speed is 29 km/h.English hovercraft "Air Ryder"

This two-seat sports apparatus is one of the most popular among amateur shipbuilders. The axial supercharger is driven by a motorcycle, dv. working volume 250 cm 3 . Propeller - two-blade, wooden; powered by a separate 24 kW motor. Electrical equipment with a voltage of 12 V with an aircraft battery. Engine start - electric starter. The apparatus has dimensions of 3.81x1.98x2.23 m; ground clearance 0.03 m; rise 0.077 m; pillow area 6.5 m 2; empty weight 181 kg. Develops a speed of 57 km / h on water, 80 km / h on land; overcomes slopes up to 15 °.Table 1. shows the data of a single modification of the device.

English SVP "Hovercat"

Light tourist boat for five or six people. There are two modifications: "MK-1" and "MK-2". The centrifugal supercharger with a diameter of 1.1 m is driven by a car. dv. "Volkswagen" with a working volume of 1584 cm 3 and consumes power of 34 kW at 3600 rpm.In the MK-1 modification, the movement is carried out using a propeller with a diameter of 1.98 m, driven by a second engine of the same type.

In the MK-2 modification, a car was used for horizontal thrust. dv. "Porsche 912" with a volume of 1582 cm 3 and a power of 67 kW. The apparatus is controlled by means of aerodynamic rudders placed in the stream behind the propeller. Electrical equipment with a voltage of 12 V. The dimensions of the apparatus are 8.28x3.93x2.23 m. The air cushion area is 32 m 2, the gross weight of the apparatus is 2040 kg, the speed of movement of the modification "MK-1" is 47 km / h, "MK-2" - 55 km/h

Notes

1. A simplified method for selecting a propeller according to known value resistance, rotational speed and translational speed is given in.2. Calculations of V-belt and chain drives can be performed using the standards generally accepted in domestic engineering.

Unsatisfactory network condition highways and the almost complete absence of road infrastructure on most regional routes makes it necessary to look for vehicles that operate on other physical principles. One such means is a hovercraft capable of moving people and goods in off-road conditions.

Hovercraft, bearing the sonorous technical term "hovercraft", differs from traditional models of boats and cars not only in the ability to move on any surface (pond, field, swamp, etc.), but also in the ability to develop a decent speed. The only requirement for such a "road" is that it should be more or less even and relatively soft.

Hovercraft, bearing the sonorous technical term "hovercraft", differs from traditional models of boats and cars not only in the ability to move on any surface (pond, field, swamp, etc.), but also in the ability to develop a decent speed. The only requirement for such a "road" is that it should be more or less even and relatively soft.

However, the use of an air cushion by an all-terrain vehicle requires quite serious energy costs, which in turn entails a significant increase in fuel consumption. The functioning of hovercraft (HVAC) is based on a combination of the following physical principles:

- Low specific pressure of SVP on the surface of soil or water.

- High movement speed.

This factor has a fairly simple and logical explanation. The area of contact surfaces (bottom of the apparatus and, for example, soil) corresponds to or exceeds the area of the SVP. Technically speaking, the vehicle dynamically generates the necessary amount of support rod.

This factor has a fairly simple and logical explanation. The area of contact surfaces (bottom of the apparatus and, for example, soil) corresponds to or exceeds the area of the SVP. Technically speaking, the vehicle dynamically generates the necessary amount of support rod.

The excess pressure created in a special device separates the machine from the support to a height of 100-150 mm. It is this cushion of air that interrupts the mechanical contact of the surfaces and minimizes the resistance of the forward movement of the hovercraft in the horizontal plane.

Despite the ability to move quickly and, most importantly, economically, the scope of the hovercraft on the surface of the earth is significantly limited. Asphalt areas, hard rocks with the presence of industrial debris or hard stones are absolutely not suitable for it, since the risk of damage to the main element of the SVP - the bottom of the pillow, increases significantly.

Despite the ability to move quickly and, most importantly, economically, the scope of the hovercraft on the surface of the earth is significantly limited. Asphalt areas, hard rocks with the presence of industrial debris or hard stones are absolutely not suitable for it, since the risk of damage to the main element of the SVP - the bottom of the pillow, increases significantly.

Thus, the optimal hovercraft route can be considered one where you need to swim a lot and in some places drive a little. In some countries, such as Canada, hovercraft are used by rescuers. According to some reports, devices of this design are in service with the armies of some NATO member countries.

Why is there a desire to make a hovercraft with your own hands? There are several reasons:

That is why SVPs have not received wide distribution. Indeed, as an expensive toy, you can buy an ATV or snowmobile. Another option is to make a boat-car yourself.

That is why SVPs have not received wide distribution. Indeed, as an expensive toy, you can buy an ATV or snowmobile. Another option is to make a boat-car yourself.

Choosing working scheme, it is necessary to determine the hull design that optimally matches the given specifications. Note that do-it-yourself SVP with assembly drawings of home-made elements is quite realistic to create.

Finished drawings makeshift ships hovercraft specialized resources abound. Analysis of practical tests shows that the most successful option, satisfying the conditions that arise when moving through water and soil, are pillows formed by the chamber method.

When choosing a material for the main structural element of an air cushion vehicle - the hull, consider several important criteria. First, it is simplicity and ease of processing. Secondly, small specific gravity material. It is this parameter that ensures that the SVP belongs to the “amphibian” category, that is, there is no risk of flooding in the event emergency stop ship.

When choosing a material for the main structural element of an air cushion vehicle - the hull, consider several important criteria. First, it is simplicity and ease of processing. Secondly, small specific gravity material. It is this parameter that ensures that the SVP belongs to the “amphibian” category, that is, there is no risk of flooding in the event emergency stop ship.

As a rule, 4 mm plywood is used to make the hull, and superstructures are made of foam. This significantly reduces the own weight of the structure. After pasting the outer surfaces with foam and subsequent painting, the model acquires its original features appearance original. Used for cabin glazing polymer materials, and the remaining elements are bent from the wire.

The manufacture of the so-called skirt will require a dense waterproof fabric made of polymer fiber. After cutting, the parts are sewn together with a double tight seam, and gluing is done using waterproof glue. This provides not only a high degree of structural reliability, but also allows you to hide from prying eyes mounting joints.

The design of the power plant involves the presence of two engines: marching and forcing. They are equipped with brushless electric motors and two-bladed propellers. A special regulator carries out the process of managing them.

The design of the power plant involves the presence of two engines: marching and forcing. They are equipped with brushless electric motors and two-bladed propellers. A special regulator carries out the process of managing them.

The supply voltage is supplied from two batteries, the total capacity of which is 3,000 milliamps per hour. At the maximum charge level, the SVP can be operated for 25-30 minutes.

Attention, only TODAY!

What else to read

THE LAST NOTES

- Amber extraction method in Belarus

- “Soon products from amber will arrive on store shelves”: trial amber mining has begun in the Brest region

- How to open an IP in Belarus

- Is it necessary to pay contributions to the social security budget for an employee who is on unpaid leave?

- What to give a man after parting