Hand carved wooden chairs. A small box for great joy. Main types of thread

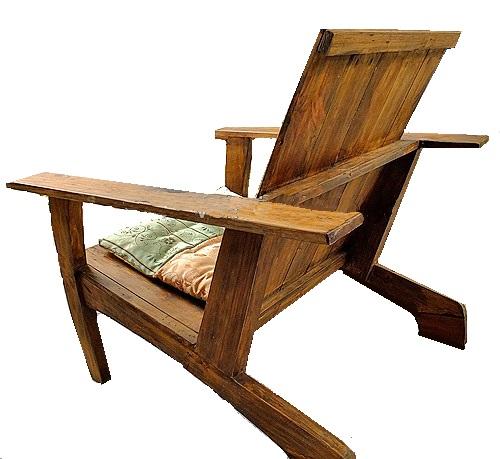

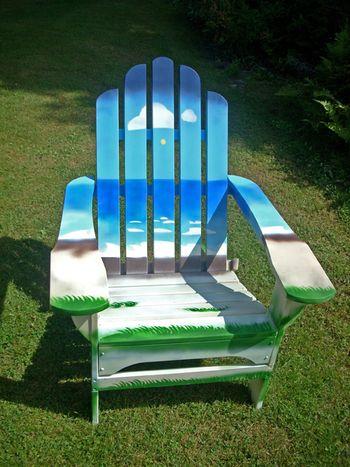

Get comfortable. On a cult chair. And contemplate the beauty of nature. Armchair "Adirondack" is a symbol of luxurious and comfortable country life. You don't even have to buy it - now you can do it wooden chair for giving and at home with your own hands!

Furniture as a cult: the legendary Adirondack chair

Sitting on the Adirondack chair, American fishermen slowly fish from the Hudson River, sitting on it, drinking cool cocktails in Haiti, tired of the bustle of businessmen, sprawled in this chair, European aristocrats enjoy the sunset on the Cote d'Azur. And it's been that way for over 110 years.

Today, this comfortable armchair is used all over the world, but only those who know its history stroke the wood of its wide armrests with special trepidation and admire its thoughtful design.

One day back in 1903, a certain Thomas Lee went on vacation to a beautiful place in the Adirondacks, in the state of New York. Enjoying life in summer house, surrounded by nature, he once realized that he needed a comfortable chair. So, to take out to the river or just sit near the house. So that there is somewhere to put a cup of coffee or a glass, so that you can sit in it with a pillow more comfortably and for a long time. And he made himself such a chair ... out of 11 rough boards found in the barn.

When his friend, a local carpenter, saw this simple furniture, he appreciated it. And even in 1905 he quietly received a patent and put the chair into production, and for the next 20 years he sold comfortable dark brown and green chairs throughout the country. Gradually, the Adirondacks began to be copied all over the world.

![]()

Jokes aside, but interior designers today do not stop admiring this chair. Known rethought designer models of the same "Adirondack" from Gino Levi-Montalcini, Gerrit Rietveld and many other designers.

And today we will try to make an Adirondack chair with our own hands!

To make a designer chair for giving, you will need

Prepare materials and tools:

- boards 6 meters: thickness 25 mm, width 14 or 15 cm - 2-3 pieces;

- wood screws 40 mm - packing;

- wood screws 70 mm (for perpendicular connection of boards) - packing;

- drill;

- drill ∅ 3 mm;

- screwdriver;

- carpentry clamps (preferably);

- square;

- roulette;

- meter ruler.

It’s great if you have a jigsaw, a circular saw and an electric planer at home, but if you rarely do carpentry work, just order a cut in the workshop (often such workshops work at construction supermarkets).

As for the boards, everything is very arbitrary: you can make everything from the same ones, or you can take a board 1.5-2 cm thick for the back and seat, but for the legs and lower crossbars you can take boards up to 7 cm thick. You can generally take boards from old pallets.

When cutting, sometimes you have to cut a lot of knots - in this case, a little more wood will be needed. In a word, just show the drawing below to the workshop and tell us about your wishes for the final look. And of course, if the boards aren't planed, ask them to plan and bevel them: you should take home the smooth, beautiful details.

Wooden chair: cutting and installation

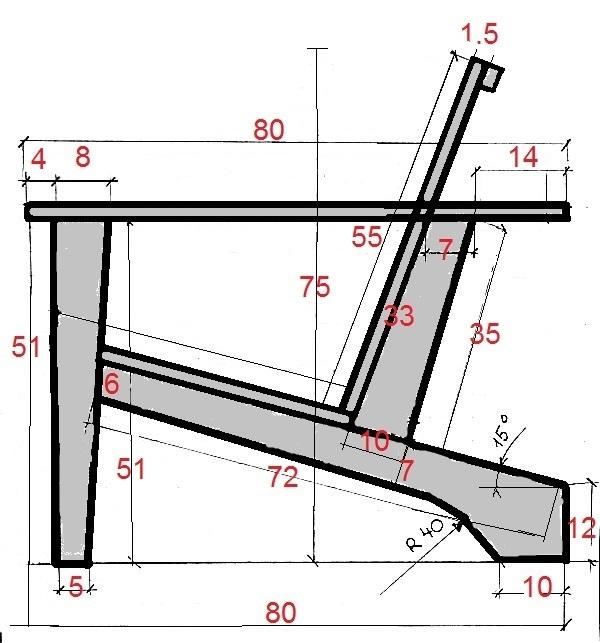

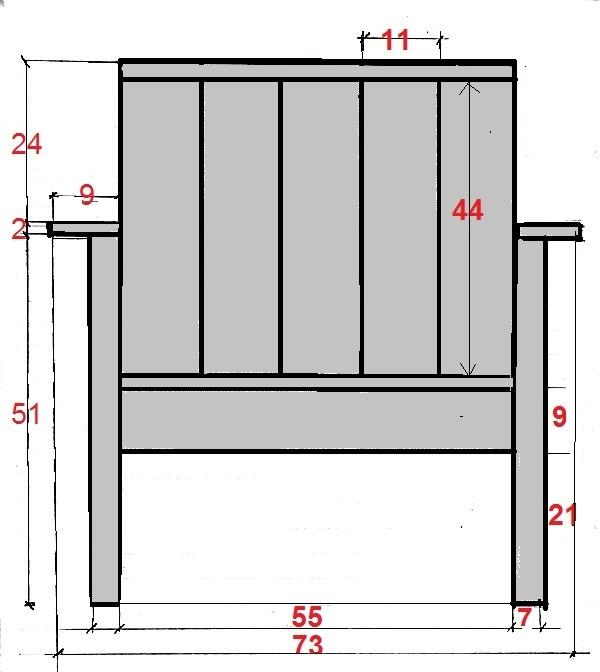

There are many variations on the theme of the Adirondack chair. We chose the simplest basic model.

In the drawing, the lower load-bearing beams are made with a bend, but for simplicity, they can be cut out in solid parts.

Let's start assembling. To prevent the boards from cracking, before screwing in the screws, you need to drill holes for them with a drill: with a 3 mm drill. We screw in the screws, you can also coat with universal sealant-glue - very convenient. At the assembly stage, it is better to use clamps or call someone to help.

In order not to confuse you with long descriptions of which part to fasten to which, here is a video:

Here is a detailed installation of a little more complex model with a curved seat and a rounded back, but the assembly principle is the same. Play the video several times and repeat the sequence.

It remains to properly sand the wood and paint it.

Armchairs, as well as other furniture that can be used both indoors and outdoors, are very comfortable. To make it last as long as possible, follow 3 rules:

- If the furniture will be used near water or in a humid climate (for example, you have a dacha by the sea), choose finely porous wood: larch, oak, as well as resistant sound areas softwood(). In drier climates, other types of wood can be used, or even beech and hornbeam parts for shipping pallets and crates.

- If you want to put the tree outside, then sit in it in the house, it would be ideal to cover it with azure for external and internal works Belinka Tophybrid, Toplasur is fine too. If you want to completely paint over the structure of the tree and give bright color, use Email Universal paint.

- Remember that if the tree is exposed to moisture (street, wet room), it must be covered with an antiseptic primer. If the furniture is always in the living room, nursery or bedroom, no primer is needed.

![]()

Ready!

That's all: put a couple of small pillows on the chair, pour lemonade into a glass and enjoy nature in comfort!

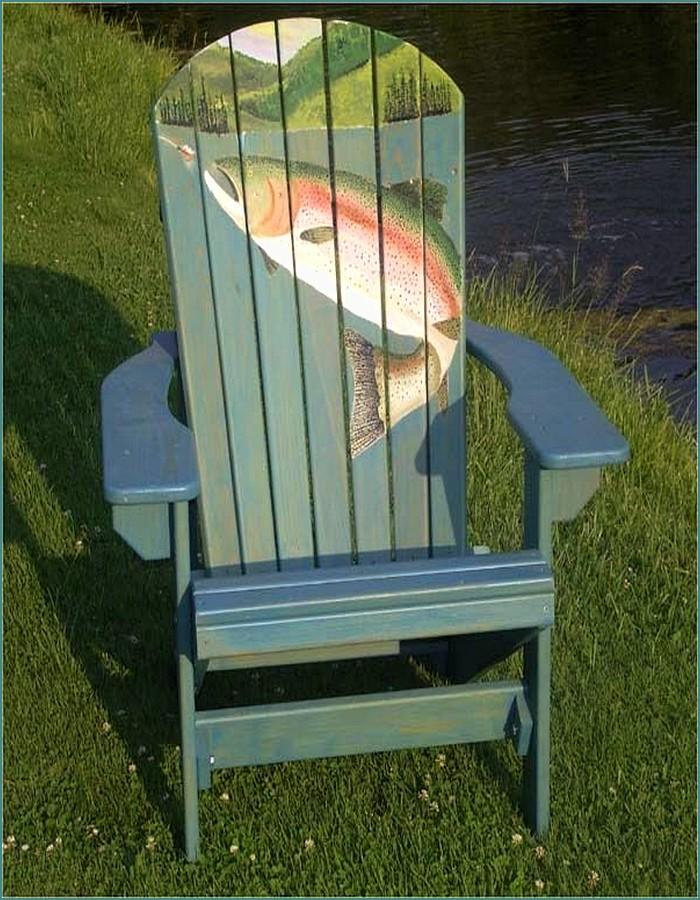

A few photo ideas for furniture design in the Adirondack style

Have questions about how to paint furniture? We will answer for free in the “Ask a Question” section on the website belinka.ru.

One has only to search for an unmistakable sign of wealth in the house, evidence of the wealth of the owner, and the furniture immediately comes into view. If the carved furniture is made by hand, then it contains not only the warmth of the master's hands, but also the special light of his creative spirit, the artistic vigilance of his gaze. Few things can compare in beauty, intricacy and elegance with carved furniture. Harmony of lines, strict observance of proportions, magnetic originality immediately attract attention to it, regardless of where it is located: in the living room or in the kitchen.

In practice, carved furniture has many advantages over upholstered furniture. It is enough to wipe the wood with a sponge moistened with water or a damp cloth, and it shines as if it had just been varnished. Upholstered furniture behaves differently: it has the ability to quickly greasy and tear. Dust from it is not easy to remove even with a vacuum cleaner. During his life, a person may well wear out three sets upholstered furniture and then take it to the dacha.

And most importantly, perhaps, lies in the fact that the excellent carved furniture can be made at home using only the tools that are at hand. In former years, our cabinet makers, making carved components, worked with ordinary tools and achieved amazing results. The masters turned out magnificent masterpieces of real art! Now there is more possibilities to make quality carved furniture than it was in the past.

Preparatory stage of work

Before you start making carved furniture, you need to prepare high-quality material for it. It is best to stock up on wood from autumn to mid-January, when the juice does not move in the trunk. This is important so that the tree does not crack. The material intended for the manufacture of carved furniture must be thoroughly dried. Its best examples are wood from birch and oak, alder and linden, elm and walnut.

In the process of work, you will need a lot of the most diverse tools, but from the range that is available to everyone and is not difficult to practical application. The main list will not be long:

Need jigsaws and compasses

Cranberries and chisels

Mallet and carpenter's square

Rasps and thicknesser

Skewers and tsarazik

Files and malka

Corners, chasers and drill

It is easiest to cut the material into blanks on a circular saw and plan them on a planer or planer. In the event that very wide blanks are needed, it is necessary to use PVA glue, with which the planks are easily glued together, after which they can be planed and cleaned by hand. The workpieces are leveled during the scraping process, it is not necessary to grind them with sandpaper. The future ornament is marked with an ordinary pencil after the workpiece is fixed on the workbench in the most convenient way for work.

Clean and varnish

As soon as the markup is over, they begin to cut out the details necessary for the further process of work. Larger elements are fixed in the machine, with small ones you can work on the table. When all the elements are cut out, assembly begins.

One of the common methods of fastening is screwing them with screws. To clean the finished products from fine dust, it is enough to wipe them twice with a break with a wet cloth and dry.

Three hours later, the product is sipped with nitro-lacquer with varnish, after which it is left for twenty-four hours to dry the coating. Needs more sanding and polishing. Four days will pass, it is necessary to polish the furniture with polish with alcohol. The treated surface will shine like a fifty-kopeck piece just released from the mint.

Carved furniture made with my own hands, is able to ennoble the interior of the room in such a way that other items purchased expensively in the store cannot do. The tradition of using carved ornaments in the manufacture of furniture goes back many centuries. Skill, gradually accumulating, gave rise to special artistic values, expressed in the appearance next to a person of elegant and beautiful products from wood. A bed with carving elements can transform the interior of a bedroom. The carved table brings new, elegant and attractive features to the kitchen design.

Wooden carved furniture has become a sign good taste, to the highest degree contributing to the formation of a cozy atmosphere in the home. In the manufacture of such products, it is not by chance that the most valuable species of wood are used. As a result, carved furniture has served faithfully for many generations, turning into a kind of family heirloom. In order for it to naturally fit into the interior, a well-thought-out decoration of the room and its specific style are required. You can find a worthy place for carved furniture in an eclectic interior.

Little box for big joy

Carved wooden furniture can be found in offices, living rooms, dining rooms and bedrooms. It matches the interior of any cottage or cottage. All of the above applies in full to the wooden box in which the housewives keep their most valuable things. The oval box, which looks like a toy tram, looks especially attractive. You can make it from birch.

The wood must be thoroughly dried beforehand. The manufacturing process can only be started after it is clear that the material is dry. First you need to process necessary boards on a planer, after making sure that they do not have defects and knots. The size of the blanks that is required is made on the surface gage. After that, it is necessary to saw off the existing material in width, trim in length. A circular saw allows you to do everything at a good level.

It is necessary to start gluing the box in such a way that this gluing is reliable and the boards do not crack at the seam. Glue must be used the most reliable. The process is best done in a carpenter's vise, using conventional spacers to help avoid damage to the box.

A wooden rectangle needs an even one, the angle from the inside is ninety degrees. This is where templates for the outer and inner oval come in handy.

It is best to sketch it first on paper, then transfer it to a plywood sheet three millimeters thick using carbon paper and cut it out using a jigsaw. If the wall of the box is one centimeter, then the outer oval should exceed the inner one by two centimeters in width and by the same number of centimeters in length. To cut out the inner oval, you also need a drawing from the template on both one and the other side for greater clarity when cutting out. The jigsaw allows you to do this neatly and accurately, so that the feature itself is preserved. From the inside, as a result of careful grinding, a perfectly clean oval comes out.

We glue the bottom and lid with the box in a vice; so as not to damage the parts, we use gaskets. Now it remains to adjust the parameters of the lid and bottom to the size of the box. It is necessary to draw an oval on them from the outside, carefully cut out and glue the legs. Grinding the box on the outside allows you to finish it appearance to the required condition. It is necessary to make a cut and grind the blank of the box and the lid: there should not be a gap between them.

Beauty is not superfluous

To begin the beauty of the box, it is necessary on its lid with grinding machine make a neat bevel, gradually, slowly, adhering to the inner pattern of the oval, carefully rotating the lid. Given the size of the product, it is better to put two small loops than one for the entire length of the box. After that, you can start carving on the box. Easiest to apply to wooden surface geometric carving. It can be drawn with maximum accuracy directly on the box and then cut out.

Patterns, which are a necessary addition, must first be drawn, then transferred to the product through a carbon paper. A bright thin spiral left by burning will look good on the edges of the lid and base. Varnishing the box can be started with nitro varnish, let it dry, treat the entire surface with fine-grained sandpaper and repeat the process twice, using oil varnish. It remains to glue the product from the inside with velvet, applying a layer of glue only to the bottom and walls. The beauty is ready for everyone to see and admire.

In the past, carved elements in the everyday life of peasants performed not only a decorative function. Often, the ornament on the platbands, the columns on the porch and the furniture in the house was applied as a talisman against all kinds of evil, which filled the world of the ancient Slavs.

Carved furniture serves as a rich decoration of the interior in the Empire or Baroque style.

Hand carved furniture modern master, it's just a beautiful element of the interior. Artistic carving on wood, which only a professional can handle, is also used in classic interior, and in baroque or empire design. To decorate your own home, a novice carver can use various woodworking techniques that are accessible even to a person without experience.

Main types of thread

Figure 1. Sketch from paper with a pencil is transferred to the wooden surface of the furniture.

According to the execution technique, there are several main types of thread:

- flat notched contour and geometric;

- openwork slotted (propyl);

- flat-relief;

- sculptural.

The differences between them are both in how the pattern is applied to the wooden surface, and in how the finished product looks. So, contour carving implies deepening the contour of the ornament with chisels with different form sting. Depending on this, the grooves can be obtained with a rounded or acute-angled bottom. But in any case, the drawing will be a contour deepened into the surface.

Geometric carving involves the creation of an ornament from individual elements triangular shape, interconnected. The simplest element-peg is performed in the following sequence:

- stick the toe (sharp corner) of the knife-jamb into the top of the triangle by 2-3 mm;

- lower the knife along the side of the triangle, cutting through the wood to the lower right vertex;

- combine the cutting edge of the knife with the cut line, take it towards you so that the toe moves to the lower left vertex of the triangle;

- pressing away from you, chop off a piece of wood.

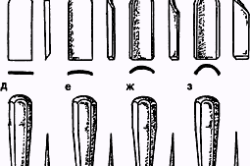

Tools for woodcarving: a, b, c, d - straight, sloping, medium, steep chisels; e - cranberry; g - cerazik; h - knife-jamb.

By connecting the pegs in a different sequence, more complex elements are obtained. Together with contour geometric woodcarving, it is available to any beginner who wants to try his hand at a new hobby.

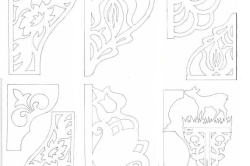

Openwork carving is performed with a jigsaw and involves the removal of wood between the details of the pattern, forming a lace pattern. If you have a tool and skills to work with it, this type of carving may well be used to decorate the head of the bed or create carved shelves and screens.

Flat-relief and sculptural woodcarving require skills and are quite difficult to do with your own hands. In the 1st case, the craftsman needs a good spatial imagination, the ability to understand how the relief pattern will look like as a result, and the ability to choose wood from the recessed parts of the pattern so as to embody the plan. In the 2nd case, sculptural compositions or figurines of animals and people are created from wood. This also requires skill and artistic gift, so it is not available to everyone.

Back to index

Tools for the job

To make carved jewelry, you will need the following tools:

- chisels with different sting shapes and different sizes;

- joint knife;

- jigsaw;

- drill;

- pencil, carbon paper, clear varnish.

The best material for carving is dense, homogeneous wood that does not split during operation: linden, birch, oak.

You can start learning the art of the carver on ready-made cutting boards from the store or pick up even planks without knots and damage. With a little practice, you can move on to making furniture.

Back to index

Furniture assembly

To begin with, a shelf can be made on the wall using the technique openwork carving. To do this, you must first draw on paper the shape of the sidewall of the shelf with a pattern. The ornament is thought out so that each of its elements is connected to neighboring ones or to the contour at least at 3 points.

You can use ready-made ideas from Fig. 1. or create your own version of the drawing based on them. Enlarge the scheme by scaling (by cells) and transfer it to the tree.

Drill a hole for a jigsaw with a drill and cut out those parts in the place of which there should be through gaps in the openwork. Process the edges of the ornament with sandpaper. For horizontal surfaces of the shelves, a thin board or plywood 5 mm thick is used.

The same detail will serve back wall shelves. If desired, it can also be decorated with carvings, the pattern of which will repeat the openwork of the sidewalls. A technique that is suitable for this purpose is contour or openwork woodcarving.

Figure 2. For the manufacture of a screen in chinese style It is better to use hardwoods.

A more difficult work to perform is a Chinese-style carved screen. It is assembled from separate parts with an ornament, which are fixed with glue on a frame of 4 bars. All structural elements and general form products are clearly visible in Fig. 2. For carved details, the technique of openwork carving was used. Ornaments cut with a jigsaw are supplemented with contour (frame around the dragon and its image, floral ornament, circles) and geometric carving (squares on the panel with the dragon). Connected parts of the screen furniture hinges on self-tapping screws.

To make a bed, you need to purchase blanks for its frame: a board for the frame and carved elements, thick plywood for the backs, a bar for the legs. Do-it-yourself woodcarving on the headboards of the bed can be done using the openwork technique, complemented by contour carving, as in the example described for making a screen.

You should start with a project on paper, which will include the dimensions and shape of the backs, the thread pattern and the location of its elements. Sawn openwork details on glue are fixed on plywood. A sheet of it can be pre-cut along the contour of the edge of the picture, if you plan to make figured carved backs.

To create an openwork composition, you will need to make cuts in the right places and in plywood base. The middle part of the head of the bed can also be made soft by sheathing it with foam rubber 2-4 cm thick and covering it with fabric. In this case carved elements will be located only along the edge of the back, forming a carved frame.

By treating work with care and attention, carefully performing operations during the carving and assembling of furniture, you can, even without having special education and skills of a furniture maker, to create beautiful things for the interior of a house or apartment with his own hands. And with experience, such a pleasant hobby as wood carving may well turn into a source of income.

Carved was popular, but its cost in stores is sometimes too high, especially when it comes to a complex pattern. Having some experience with natural wood, you can make unusually beautiful furniture for your own home with your own hands.

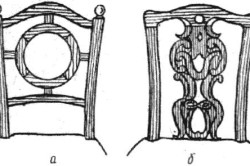

Compression of chair joints during gluing: a - clamps and a belt tie, 1 - a clamp, 2 - a belt tie, 3 - a piece of a bar or board, b - a rope.

Tables, chairs, armchairs - all this is available for hand-made production. All you need is skill, imagination and patience, as wood carving is a long and painstaking process.

If there is no experience in doing such work, then you can start by making a small stool with carved legs. Gradually, you can move on to the manufacture of tables, chairs, carved for the room. It is necessary to do the work based on certain rules and requirements, choosing the type of thread that is most suitable.

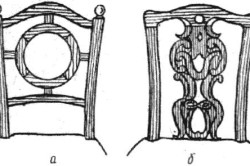

Chair Thread Examples

Wood carving can be traditional and extraordinary. The choice of a specific method depends on whether there is work experience, what tools are available. Furniture decoration methods include:

Figure 1. Drawing of a stool.

- Through thread, which is considered one of the simplest. 2 methods are used: sawn thread, when the sections are cut out, and slotted, when through holes knocked out with chisels or chisels. If a relief ornament is used, then this variant of the through thread is called openwork.

- Flat thread. It has a flat background decorative elements like going deep into it. There are many subspecies of such carving. Popular contour, based on cutting grooves with a corner chisel, with knives. Staple carving is leaving a mark on the tree in the form of a bracket. The ornament is unusual. Geometric carving is performed in 2 stages. This is a tattoo of a drawing and its trimming, as a result, beautiful trihedral patterns are obtained, they are rhombuses, honeycombs, viteiki, radiance, chains and so on. Black-lacquer carving involves the use of a varnished surface as a background. On the finished background, patterns of various depths are cut through. The result is an unusual and contrasting carving, which gives the product an original appearance.

- Relief carving for furniture, which is often used, but it is necessary to have experience in such work. It features a flat-relief carving, that is, a kind of ornament with a selected background. The difference is that the background is made below the ornament, it is specially chosen for this with a chisel. Unusual Kudrinskaya carving depicting birds, animals, incredible beautiful garlands with leaves. Art originated thanks to the master Vasily Voronov from the village of Kudrino, from where its name came from.

- Sculptural carving is a separate variety, it is used extremely rarely for furniture, as it requires skill.

If there is no experience, then it is best to start with simple options gradually improving skills. In addition, for complex types of threads, special machines are used that allow processing volumetric parts.

Back to indexStages of manufacturing carved furniture

A do-it-yourself stool is an option for beginners. For work, it is necessary to prepare certain materials and tools:

Dependence of the quality of the structure on the design: a - fragile part due to a large number connections, b - a solid part of a solid carved board.

- Pine boards. They are the easiest to process, have a beautiful appearance and aroma of needles. You can take not only pine, but also birch boards, alder, linden, oak or elm is suitable for work.

- A set of carpentry tools, including a hammer, chisel, jigsaw, saw, drill.

- Screwdriver and a set of elements for fasteners.

- Stain for painting furniture of the selected color, instead of it you can use oil, paint. To protect the wood, a transparent glossy or matte varnish is used.

Before making a carved chair, you need to draw up a drawing, choose a pattern for carving, draw up a diagram of its implementation. If there is no experience, then it is better to start with simple patterns.

For the back, you can even use plywood sheets, which are easier to cut than wooden plank and their cost is lower.

An example of a scheme for a stool is shown in Fig. 1.

How to get started? The process of carving and making a chair includes the following steps:

Curved chair.

- Start to make carved chairs and stools from wood processing, as the appearance of a piece of furniture, durability, and the absence of cracks on the surface will depend on this. Wood is taken in autumn or winter harvest so that the movement of juices in it is minimal. These blanks will not crack. If ready-made boards are used, they must be perfectly dried, free of large defects, such as falling knots, resin drips, cracks, and so on. The best materials pine, oak, birch, alder, linden, birch are considered for home furniture.

- For work, you need to choose only high-quality tools that are designed for carving. Today in stores you can buy ready-made kits, but their cost is quite high, and individually such tools can come out much cheaper. Some of them are in many homes. These are chisels, jambs, thicknesses, cranberries, corners, bevel, tsarazik, files, mallet, chased, cut, electric jigsaw, drill and others. It all depends on what kind of thread is required, what will be the level of complexity.

- The boards are laid out on horizontal surface, start cutting. To do this, it is necessary to mark the surface of the boards in accordance with the drawing. It is advisable to put a designation on each element to make it easier to assemble finished parts. If there is a circular saw, then cutting is much easier. If it is not there, you can use an electric jigsaw. If you use thicker elements for furniture, then they will have to be glued with PVA.

- After all the parts are cut and glued, it is necessary to clean up. Beginners make the mistake of using sandpaper. In the manufacture wooden furniture At this stage, you need to use only looping. Then the finished carving blank is mounted on a workbench, a pattern is applied to the surface with a simple pencil and a stencil (if used). It is necessary to fix the part carefully, since during operation it is necessary to observe maximum accuracy and accuracy, otherwise the hands can be easily injured.

- When the markup is applied, you can start cutting. It all depends on which method will be used to work. For simple options, just cut holes various shapes using a jigsaw. If a complex volumetric thread is used, then special machines will be needed. Therefore, experts recommend starting with simple forms.

- Chair Thread Examples

- Stages of manufacturing carved furniture

- How to collect chairs?

Carved furniture has always been popular, but its cost in stores is sometimes too high, especially when it comes to a complex pattern. Having some experience working with natural wood, you can make an unusually beautiful and stylish furniture for your own home.

Compression of chair joints during gluing: a - clamps and a belt tie, 1 - a clamp, 2 - a belt tie, 3 - a piece of a bar or board, b - a rope.

Tables, chairs, armchairs, cabinets - all this is available for hand-made production. All you need is skill, imagination and patience, as wood carving is a long and painstaking process.

If there is no experience in doing such work, then you can start by making a small stool with carved legs. Gradually, you can switch to the manufacture of tables, chairs, carved panels for the room. It is necessary to do the work based on certain rules and requirements, choosing the type of thread that is most suitable.

Chair Thread Examples

Wood carving can be traditional and extraordinary. The choice of a specific method depends on whether there is work experience, what tools are available. Furniture decoration methods include:

Figure 1. Drawing of a stool.

- Through thread, which is considered one of the simplest. 2 methods are used: sawn thread, when sections are sawn out, and slotted, when through holes are knocked out with chisels or chisels. If a relief ornament is used, then this variant of the through thread is called openwork.

- Flat thread. It has a flat background, and the decorative elements seem to go deeper into it. There are many subspecies of such carving. Popular contour, based on cutting grooves with a corner chisel, with knives. Staple carving is leaving a mark on the tree in the form of a bracket. The ornament is unusual. Geometric carving is performed in 2 stages. This is a tattoo of a drawing and its trimming, as a result, beautiful trihedral patterns are obtained, they are rhombuses, honeycombs, viteiki, radiance, chains and so on. Black-lacquer carving involves the use of a varnished surface as a background. On the finished background, patterns of various depths are cut through. The result is an unusual and contrasting carving, which gives the product an original appearance.

- Relief carving for furniture, which is often used, but it is necessary to have experience in such work. It features a flat-relief carving, that is, a kind of ornament with a selected background. The difference is that the background is made below the ornament, it is specially chosen for this with a chisel. Unusual Kudrinskaya carving depicting birds, animals, flowers, incredibly beautiful garlands with leaves. Art originated thanks to the master Vasily Voronov from the village of Kudrino, from where its name came from.

- Sculptural carving is a separate variety, it is used extremely rarely for furniture, as it requires skill.

If there is no experience, then it is best to start with simple options, gradually improving skills. In addition, for complex types of threads, special machines are used that allow processing volumetric parts. Back to index

Stages of manufacturing carved furniture

A do-it-yourself stool is an option for beginners. For work, it is necessary to prepare certain materials and tools:

Dependence of the quality of the structure on the design: a - a fragile part due to the large number of joints, b - a strong part made of a solid carved board.

- Pine boards. They are the easiest to process, have a beautiful appearance and aroma of needles. You can take not only pine, but also birch boards, alder, linden, oak or elm is suitable for work.

- A set of carpentry tools, including a hammer, chisel, jigsaw, saw, drill.

- Screwdriver and a set of elements for fasteners.

- Stain for painting furniture of the selected color, instead of it you can use oil, paint. To protect the wood, a transparent glossy or matte varnish is used.

Before making a carved chair, you need to draw up a drawing, choose a pattern for carving, draw up a diagram of its implementation. If there is no experience, then it is better to start with simple patterns.

For the back, you can even use plywood sheets, which are easier to cut than a wooden board, and their cost is lower.

An example of a scheme for a stool is shown in Fig. 1.

How to get started? The process of carving and making a chair includes the following steps:

- They begin to make carved chairs and stools from wood processing, since the appearance of a piece of furniture, durability, and the absence of cracks on the surface will depend on this. Wood is taken in autumn or winter harvesting, so that the movement of juices in it is minimal. These blanks will not crack. If ready-made boards are used, they must be perfectly dried, free of large defects, such as falling knots, resin drips, cracks, and so on. The best materials for home furniture are pine, oak, birch, alder, linden, birch.

- For work, you need to choose only high-quality tools that are designed for carving. Today in stores you can buy ready-made kits, but their cost is quite high, and individually such tools can come out much cheaper. Some of them are in many homes. These are chisels, jambs, thicknesses, cranberries, corners, bevel, tsarazik, files, mallet, chased, cut, electric jigsaw, drill and others. It all depends on what kind of thread is required, what will be the level of complexity.

- The boards are laid out on a horizontal surface, cutting begins. To do this, it is necessary to mark the surface of the boards in accordance with the drawing. It is advisable to put a designation on each element to make it easier to assemble finished parts. If there is a circular saw, then cutting is much easier. If it is not there, you can use an electric jigsaw. If you use thicker elements for furniture, then they will have to be glued with PVA.

- After all the parts are cut and glued, it is necessary to clean up. Beginners make the mistake of using sandpaper for sanding. In the manufacture of wooden furniture at this stage, only sanding should be used. Then the finished carving blank is mounted on a workbench, a pattern is applied to the surface with a simple pencil and a stencil (if used). It is necessary to fix the part carefully, since during operation it is necessary to observe maximum accuracy and accuracy, otherwise the hands can be easily injured.

- When the markup is applied, you can start cutting. It all depends on which method will be used to work. For simple options, it is enough to cut holes of various shapes using a jigsaw. If a complex volumetric thread is used, then special machines will be needed. Therefore, experts recommend starting with simple forms.

What else to read

THE LAST NOTES

- Preparing your home for Easter Preparing for Easter by day of the week

- Instructions: preparing for Easter Calendar of work for Holy Week

- Canned cucumbers for the winter

- The Holy Spirit: how and why He dwells with Christians What is the spirit in Christianity

- Velikoretsky procession What is worn during the procession