Guide to Clamps and Clamps

Clamps are an indispensable tool for every carpenter. It is difficult to imagine a master who is able to do without these devices in his work. There are quite a few varieties of clamps and clamps, while manufacturers do not stop looking for new solutions to make their tool even more convenient, functional and adapted to specific carpentry tasks.

In our material, we will talk in detail about the main types of wood clamps: we will tell you what different models of clamps consist of and how they work, consider the advantages and disadvantages of each of them, and give useful tips on how to choose a clamp for specific carpentry tasks.

G clamps

Design features. G-shaped clamps, also often referred to as C-shaped, are the most versatile and mass type of carpentry clamps. The basis of the design is a cast or forged bracket with a movable clamping screw.

Advantages. L-shaped clamps are light, easy to use, provide high clamping force, do not have gaps in the jaws.

disadvantages. Suitable for joining workpieces of small thickness.

Application area. G-shaped clamps are used in cases where it is necessary to apply the same compressive force to surfaces that are parallel to each other. In carpentry, C-clamps are mainly used when gluing wood together.

F clamps

Design features. The clamp consists of a guide rail on which the movable and fixed jaws are fixed. The movable bracket, sliding along the guide, has a set screw that allows you to adjust the desired length of the grip and prevents the clamp from loosening. Sponges complete with overlays for protection of the fixed surfaces.

Advantages. The main advantage of F-shaped clamps is their versatility. The adjustable grip length makes it possible to firmly and strongly fix workpieces of various thicknesses.

disadvantages. It is not always convenient to work with an F-shaped clamp, because. You have to use both hands to manipulate the tool.

Application area. Used for fixing wooden products and blanks of various thicknesses.

End clamps

Design features. The end clamp consists of a cast or forged base-bracket with three clamping screws.

Advantages. A simple and affordable design for specific carpentry tasks: the T-profile clamp is used for clamping edges and ends.

Disadvantages. For all its functionality, it is not so easy to cope with the end clamp: fixing the edge, simultaneously holding the clamp and tightening the three clamps is not always convenient alone.

Application area. Clamping edges and end elements of wooden products.

Angle clamps

Design features. Clamps for corner joints can have a variety of designs. A typical design consists of a body, one or two screw clamps with clamping heels.

Advantages. Simple and compact fixture for clamping workpieces at right angles. Such clamps are often supplemented with special holes for fastening to a workbench.

disadvantages. Limited opportunities when working with overall wooden elements.

Application area. Clamps for gluing and fixing wood at right angles. Creating connections on the mustache.

Keyless (automatic) clamps

Design features. A typical design of a quick-release clamp consists of a metal bar and two plastic jaws (movable and fixed). The moving part is pressed by means of a special lever mechanism. The lightweight and durable body of quick-clamp clamps is made of plastic composites reinforced with fiberglass. This allows the use of automatic clamps in almost any conditions.

Advantages. One-handed options are perhaps the most convenient and ergonomic type of clamps. How to use such clamps is intuitive: all manipulations are performed with one hand, while the other holds the part. Even the smallest quick-acting clamps have tremendous clamping force.

Most lever models have a transforming design that expands the capabilities of the tool. For example, on some models, you can turn the jaws in opposite directions, to work by surprise, which is very convenient when disassembling spiked joints. Two quick-clamp clamps can be easily reconfigured into one long one by interlocking the protrusions on the fixed jaws.

disadvantages. High-quality automatic clamps are quite expensive, and almost all budget counterparts are not highly reliable.

Application area. Quick-release clamps are used for all types of carpentry work: from fixing small parts to gluing large boards.

Spring clamps

Design features. Clamps with non-adjustable clamping force, working on the principle of a clothespin. A popular variation of the classic spring clamp are designs with a variable clamp width.

Advantages. Clamps are lightweight and comfortable, all manipulations when working with them are performed with one hand. They provide a stable, powerful clamping force. Optimal for delicate fixation of parts to be glued.

disadvantages. Small depth of capture.

Application area. Universal device for gluing and fixing oversized parts.

Tape clamps

Design features. The band clamp consists of a strong synthetic band and a tensioning block. The package usually includes plastic elements for fitting corners.

Advantages. Provides gentle clamping of corners and roundings without distortion, which is very important at the gluing stage. Allows you to work with products of any size: from small frames to large cabinets. The use of plastic corner elements ensures uniform pressure when gluing corners and miter joints.

Application area. The choice of band type clamps is the best option for complex carpentry tasks: clamping large diameter roundings, fixing polygonal joints, etc.

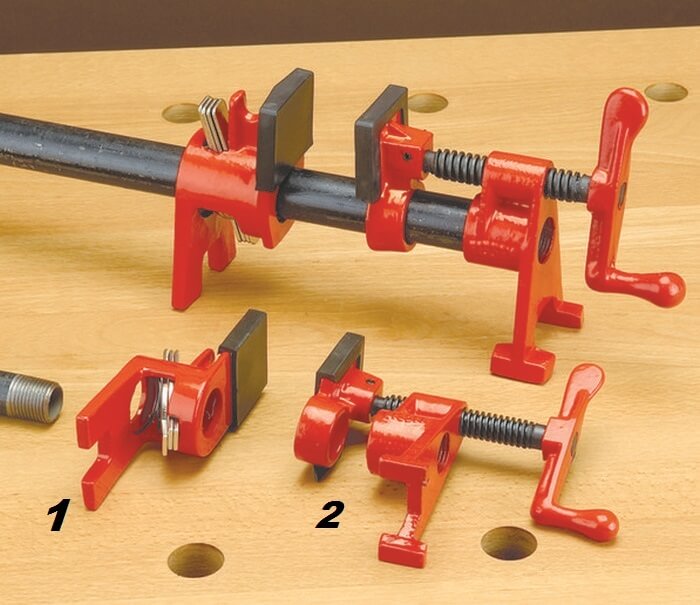

Pipe clamps

What else to read

THE LAST NOTES

- DIY rocking chair (59 photos): drawings, convenient options, tips for creating

- Cover for a chair with a backrest with your own hands - patterns plus fantasy

- DIY rocking chair: materials and drawings with dimensions

- Do-it-yourself bumpers in the crib: a manifestation of parental love and care

- An excellent design solution to make a built-in wardrobe from hl