DIY rocking chair: materials and drawings with dimensions

The rocking chair has always been a very convenient item for relaxing in the country or in a country house. But not every fan of such a holiday knows that it is possible to make a rocking chair with your own hands if you have certain knowledge, skills and a simple tool. Moreover, the rocking chair is associated not only with countryside recreation. Now there are many models of this type of furniture for apartments and even offices. Manufacturing variations differ from the standard wicker version to the modern armchair in.

Rattan rocking chair

As we said above, the variety of rocking chairs in modern life is impressive. For example, a rattan rocking chair has a cozy appearance and will fit perfectly into the interior of your summer cottage. Rattan is a plant that grows in the forests of South America and is also called a flexible liana.

Note!

In terms of strength, it is not much inferior to willow twigs.

Armchairs from this culture are woven without the use of screws and bolts, and all connections are made with glue and skillful knitting. Unfortunately, rattan does not grow and is not sold with us, only in the finished product, so making such a chair with your own hands seems unlikely.

Wicker chair

A very popular look is the wicker rocking chair. A common element of any summer cottage or even an apartment in our latitudes. Such an armchair is woven from willow vines and looks great against the backdrop of a garden house, cottage or greenery of your garden. Willow wicker rocking chairs are lightweight and very durable. But such furniture has one small drawback. When it is damp or raining outside, it is advisable to hide such chairs in the house, as they are afraid of excess moisture.

Chair material

Wicker chairs made of rattan and wicker require special skills. Therefore, if we are going to make a rocking chair with our own hands, then the most acceptable option would be wooden. Let's look at what we may need to make it:

- with a set of blades.

- Disc type grinder with coarse and fine-grained nozzles.

- with drills.

- Roulette and corner with a ruler.

- Hammer and.

- Brushes, pencil.

Execution of the drawing

Before starting work on making a chair, you need to draw a simple drawing of a plywood rocking chair. An example of such a drawing is shown below.

First of all, it is needed for the precise manufacture of the product and the correct calculation of the required material. Let's put on a metric grid, in increments of 1 cm, a template for the side of the chair. Then, for convenience, we transfer the resulting chair template to plain paper. Then it will be easier for us to transfer the contour of the chair to plywood. Don't be afraid of small inaccuracies. It is important that the sidewalls are identical and that there are no protruding corner elements in the lower rolling part.

Detail cutting

First you need to cut out of plywood, 3 cm thick, three drawers (in other words, a screed) measuring 120 by 800 mm. The sidewalls are cut using an electric jigsaw strictly according to the pattern. Then we take a bar 50 mm wide and 25 mm thick and cut 35 pieces 120 cm long. From these bars we will subsequently make a seat and back.

Consider the amount of waste from the purchased timber. The total length of the beam can be easily calculated before buying, and if, for example, its length is 2.3 m, then it is better to make the width of the chair a little narrower, it will be 115 cm, but do without waste. The dimensions of the rocking chair are not dogma, and if you see that they need to be changed a little to make better use of the material, then you can do it without problems.

Workpiece processing

Using a grinder, you need to process the surfaces of the resulting workpieces and especially their ends. The protruding wood fibers at the ends must be flattened with a hammer, and then treated with hot drying oil. This will protect the ends of your chair from moisture and prolong its life. After drying, you will need to process them again.

Product assembly

Using the drawings of the rocking chair, we begin to assemble the product. We connect with the help of the tsarg two sidewalls. To do this, we mark the places of their fixation. Logically, the best option would be to install them in the head area, in the middle and at the legs.

Note!

The fixing of the tightening strips to the sidewall must be done with the help of a confirmation.

Confirmat is a screw screed for joining wood materials. Previously, before fastening, we drill holes in the sidewall of 8 mm and in the end of the sidewall of 5 mm.

After that, we proceed to the manufacture and fastening of the seat. To do this, in each bar, we recall that we have as many as 35 pieces, we make four holes, two on each side. And then we attach the bars to the sidewalls. For this frequency of fastenings, a three- or four-mm self-tapping screw can be used as a retainer. Do not forget that in the process of fixing such a number of planks, you need to periodically check the evenness of their installation. A video instruction for assembling a rocking chair is in this article.

Processing the finished assembled chair

Analyzing the reviews of amateurs who were engaged in self-assembly of rocking chairs made of wood and plywood, we can say that one of the main mistakes after assembly is poor-quality finishing or its absence at all. Therefore, it must be recalled that for the longest possible service of the chair, it is required:

- holes above the screws.

- Treat with an antiseptic.

- Two or three times you need to treat the surface with a waterproof varnish.

- It is better to make wooden chairs from high-quality types of wood. Such material is needles, oak, larch. They have high strength, ductility and moisture resistance. A good option would be to use euro plywood. Armchairs made of such wood will last as long as possible.

- Plywood sheets should be selected with good plasticity, for easier subsequent processing.

- Be sure to finish even when using high-quality wood. This will greatly increase the life of the product.

- It is strongly not recommended to sheathe the chair with foam rubber or fabric. The wood under it will rot and rot, which will significantly reduce the life of the product.

- Try to keep furniture under a canopy, in a gazebo, or bring it home in wet weather to avoid unnecessary wetting.

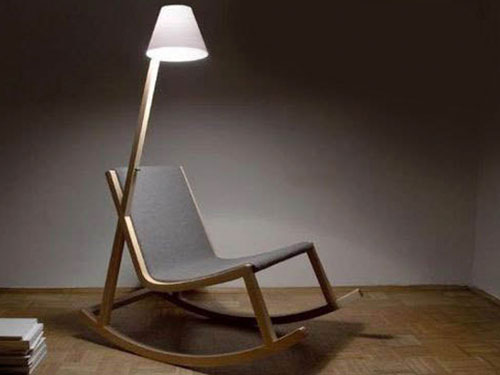

Rocking chair with lamp

Other types

There is another type of wooden chairs for children. The principle of their manufacture is identical to the above option, only when crafting it is necessary to take into account smaller dimensions, a different backrest slope and the presence of handles. A horse is often used as a chair.

A very original version of the product is a rocking chair for the office. It is covered with leather, and it has a very respectable, solid appearance. On such a chair, during the working day, you can relax and unwind.

High-tech rocking chairs are distinguished by their very original design. Note that the listed furniture is manufactured in a factory way, has a complex design and is difficult to make on your own.

DIY rocking chair video:

In contact with

See inaccuracies, incomplete or incorrect information? Do you know how to make an article better?

Would you like to suggest photos for publication on a topic?

Please help us make the site better! Leave a message and your contacts in the comments - we will contact you and together we will make the publication better!

What else to read

THE LAST NOTES

- DIY rocking chair (59 photos): drawings, convenient options, tips for creating

- Cover for a chair with a backrest with your own hands - patterns plus fantasy

- DIY rocking chair: materials and drawings with dimensions

- Do-it-yourself bumpers in the crib: a manifestation of parental love and care

- An excellent design solution to make a built-in wardrobe from hl