How to make an exclusive and comfortable easy chair yourself at home from improvised materials. Drawings and stages of assembling an easy chair, taking into account individual characteristics and human physiology - How to make furniture yourself

After a working day, it's nice to relax in your favorite soft armchair in front of the TV or with a newspaper. But not all seats are comfortable or comfortable. In the course of creating furniture for myself, I asked myself: how to make an easy chair? For some reason, this piece of furniture is unreasonably expensive if you buy it in a store or order it from craftsmen. While a hand-made easy chair will cost you several times less, besides, you can fully adapt it to suit you and your interior.

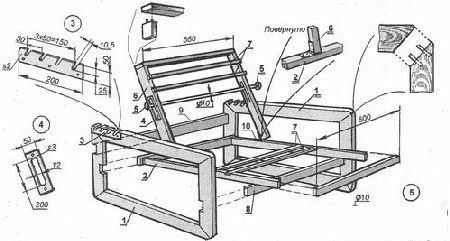

In this version of the soft chair, there are no complex connections of parts in the structure, since the frame will hold the plywood, which will be attached to the back and seat over the entire plane:

The skeleton of the backrest and two parts of the seat of the chair will be assembled according to the principle of overlays, as in simple boxes. The joints can be additionally put on glue and corners. But the main thing is self-tapping screws, they will be screwed on 2 pcs. for each joint of the chair frame.

You should start from the base (seat frame):

We make 4 supporting legs of an easy chair from bars of preferably strong rock with a section of 70 by 70 mm and a height of 100 mm. We attach crossbar bars with a section of 40 by 40 mm to them. You can attach them to metal corners for reliability.

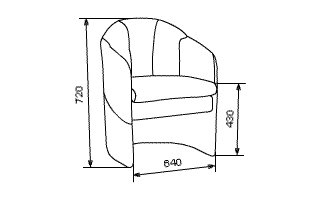

The width and length of the chair is a purely individual matter. I will only say one thing, that when planning the size of an easy chair, the base will set all the parameters.

We assemble the back of the chair:

It is advisable to make it at an angle. In our case, the skeleton consists of 2 horizontal and 4 vertical boards 30 mm thick. The height of the backrest is also a value that we determine for ourselves, depending on height and habits. Sit on the chair frame several times and determine the optimal backrest for you.

Plywood is completely superimposed on the skeleton of the chair in the back part, and from the side, where we will lean with our backs, only on the open part. The lower part will close the seat:

We cover plywood with batting on all sides:

We connect the back of the chair with the base and mark the size of the future collapsible seat.

We assemble the lower part of the chair seat:

It consists of two long and three short boards, one of which in the middle serves for strength and for forming compartments for small items inside the chair - remote controls, glasses, brushes and more. The bottom is made of plywood.

We sheathe the resulting module with a cloth using a construction stapler. Then we put it in place, attaching it to the base and back of the chair:

The upper part of the seat of the chair will consist of thick plywood and a thick layer (20-25 cm) of foam rubber:

We sheathe plywood with foam rubber with a cloth. We fasten the upper part of the seat of the chair with loops to the lower part.

The soft chair is ready. You will need the bare minimum of tools. Every home DIYer has a square ruler, a drill driver, a jigsaw, a hammer, a stapler, and maybe something else from the little things.

It is also necessary to take into account several specific features of the assembly of an easy chair:

For the base of an easy chair, it is best to take boards with a thickness of at least five centimeters and a width of about 15 cm. In addition, you will need self-tapping screws 10 cm long or more, as well as bars to reinforce the corners of the base. With the help of self-tapping screws, the boards are assembled into the base of the chair. The standard size of the base is 70x65 cm, but these figures may vary depending on individual needs.

.

Chair bottom

As the bottom of the sofa, fiberboard is optimal. To strengthen the bottom, we saw down several rails into the base, onto which fiberboard is nailed. This method will avoid sagging of the bottom of the chair.

Chair seat and back

For the manufacture of the seat and back of an easy chair, boards of 15 * 5 cm are also required. A box is assembled from the boards, similar to the base of the chair (size 65 * 70 cm). The backrest is upholstered with fiberboard sheets on both sides. The outer part of the back is covered with polyurethane foam wrapped in holofiber, providing softness and elasticity.

From above, the box of the backrest and the seat of the chair must be strengthened, however, in this case, not the slats, as in the base, but 5 * 5cm bars are sawn. The optimal distance between the bars is from 8 to 10 cm. Legs from the treated timber are screwed to the base from below.

The sides of the chair are made of chipboard or assembled from boards and upholstered with plywood. Finished sidewalls can be pasted over with polyurethane foam. To give softness, the sidewalls can be wrapped with synthetic winterizer or holofiber.

What else to read

THE LAST NOTES

- DIY rocking chair (59 photos): drawings, convenient options, tips for creating

- Cover for a chair with a backrest with your own hands - patterns plus fantasy

- DIY rocking chair: materials and drawings with dimensions

- Do-it-yourself bumpers in the crib: a manifestation of parental love and care

- An excellent design solution to make a built-in wardrobe from hl