How to adjust idle speed on a vaz 2106

Engine idle adjustment should ensure the lowest possible amount of toxic substances in the exhaust gases. If the standards for the content of toxic substances are exceeded, the operation of the VAZ 2106 car is prohibited.

A WARNING

Adjust the idle speed with the air filter installed on a warm engine (coolant temperature 90-95 ° C) with the fuel level in the float chamber and clearances in the valve drive adjusted and the ignition timing correctly set. The choke should be fully open (visually check this through the carburetor throat). Since the adjustment of the crankshaft speed at idle and the content of carbon monoxide (CO) in the exhaust gases is carried out together, and a gas analyzer is required to adjust the CO content, we recommend that these operations be performed at a service station.

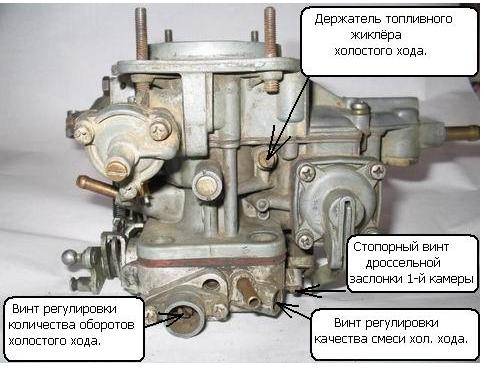

The location of the screws for adjusting the idling system: 1 - the screw for the composition (quality) of the mixture; 2 - mixture quantity screw.

NOTES

The screws are located deep in the sockets of the throttle body, so screw 1 is not visible in the photo. On a new VAZ 2106 car, plastic restrictive bushings are pressed onto screws 1 and 2, allowing you to turn the screws only half a turn. This is done to prevent violating the factory setting. If it is not possible to adjust the CO content in the exhaust gases with the bushings, then, by unscrewing the screws, break the heads of the bushings, unscrew the screws, remove the remains of the bushings from them and tighten the screws again.

1. Start the engine on the VAZ 2106 car. By turning screw 2 of the mixture amount, set the engine crankshaft speed within 750-800 min. When the screw is turned in, the speed decreases, when it is loosened, it increases.

2. Then check and, if necessary, adjust the CO content. We recommend setting the CO content to (1±0.3)%. Adjustment is carried out with screw 1 of the composition (quality). When the screw is turned in, the CO content decreases, and when the screw is loosened, it increases.

According to amendment No. 1 to GOST 17.2.2.03-87, which entered into force on January 1, 2000, the CO content in the exhaust gases of vehicles (if it is not specified by the manufacturer in the operating manual) equipped with a carburetor and not having a catalytic converter in exhaust system, at a crankshaft speed of 800 min should not exceed 3.5%. Don't reduce

the CO content is below 0.4%, since in this case, due to the misfire of the working mixture in the exhaust gases, the content of unburned hydrocarbons (CH) sharply increases. When adjusting the CO content, the crankshaft speed changes slightly.

3. Restore the initial crankshaft speed of 750-800 min with screw 2 and check the CO content. If necessary, readjust the CO content and then the speed. Depress the accelerator pedal sharply and release it. The engine should increase the crankshaft speed without interruption, and after releasing the pedal, it should not stall. If the engine has stopped, increase the speed with screw 2 up to 800 min, but no more.

USEFUL ADVICE

In the absence of a gas analyzer, it is possible to adjust the idle speed with sufficient accuracy by controlling the engine crankshaft speed using the tachometer in the instrument cluster of the VAZ 2106 car. Gently turning screw 1 (quality) in the right direction, set it to the position at which the idle speed is maximum. Then screw 2 (quantity) set the frequency to 1100 min. Gradually screwing in the quality screw, reduce the frequency to 800 min. If the carburetor is in good condition, the CO content in the exhaust gases with this adjustment method will not exceed 2%, which is within the permissible limits.

Engine idle adjustment should ensure the lowest possible amount of toxic substances in the exhaust gases. If the standards for the content of toxic substances are exceeded, the operation of the VAZ 2106 car is prohibited.

A WARNING

Adjust the idle speed with the air filter installed on a warm engine (coolant temperature 90-95 ° C) with the fuel level in the float chamber and clearances in the valve drive adjusted and the ignition timing correctly set. The choke should be fully open (visually check this through the carburetor throat). Since the adjustment of the crankshaft speed at idle and the content of carbon monoxide (CO) in the exhaust gases is carried out together, and a gas analyzer is required to adjust the CO content, we recommend that these operations be performed at a service station.

The location of the screws for adjusting the idling system: 1 - the screw for the composition (quality) of the mixture; 2 - mixture quantity screw.

NOTES

The screws are located deep in the sockets of the throttle body, so screw 1 is not visible in the photo. On a new VAZ 2106 car, plastic restrictive bushings are pressed onto screws 1 and 2, allowing you to turn the screws only half a turn. This is done to prevent violating the factory setting. If it is not possible to adjust the CO content in the exhaust gases with the bushings, then, by unscrewing the screws, break the heads of the bushings, unscrew the screws, remove the remains of the bushings from them and tighten the screws again.

1. Start the engine on the VAZ 2106 car. By turning screw 2 of the mixture amount, set the engine crankshaft speed within 750-800 min. When the screw is turned in, the speed decreases, when it is loosened, it increases.

2. Then check and, if necessary, adjust the CO content. We recommend setting the CO content to (1±0.3)%. Adjustment is carried out with screw 1 of the composition (quality). When the screw is turned in, the CO content decreases, and when the screw is loosened, it increases.

According to amendment No. 1 to GOST 17.2.2.03-87, which entered into force on January 1, 2000, the CO content in the exhaust gases of vehicles (if it is not specified by the manufacturer in the operation manual) equipped with a carburetor and not having a catalytic converter in the exhaust system , at a crankshaft speed of 800 min should not exceed 3.5%. Don't reduce

the CO content is below 0.4%, since in this case, due to the misfire of the working mixture in the exhaust gases, the content of unburned hydrocarbons (CH) sharply increases. When adjusting the CO content, the crankshaft speed changes slightly.

3. Restore the initial crankshaft speed of 750-800 min with screw 2 and check the CO content. If necessary, readjust the CO content and then the speed. Depress the accelerator pedal sharply and release it. The engine should increase the crankshaft speed without interruption, and after releasing the pedal, it should not stall. If the engine has stopped, increase the speed with screw 2 up to 800 min, but no more.

USEFUL ADVICE

In the absence of a gas analyzer, it is possible to adjust the idle speed with sufficient accuracy by controlling the engine crankshaft speed using the tachometer in the instrument cluster of the VAZ 2106 car. Gently turning screw 1 (quality) in the right direction, set it to the position at which the idle speed is maximum. Then screw 2 (quantity) set the frequency to 1100 min. Gradually screwing in the quality screw, reduce the frequency to 800 min. If the carburetor is in good condition, the CO content in the exhaust gases with this adjustment method will not exceed 2%, which is within the permissible limits.

Quite often, after a certain time of operation of the car, the owners of the VAZ 2106 are faced with the fact that the car starts to stall during idling. There can be quite a few reasons for this, but the main one is a failure to adjust the idle. As part of this article, we will try to explain how to independently adjust the idle speed and thereby correct the malfunction that has occurred.

What does the idle system of the VAZ 2106 carburetor consist of

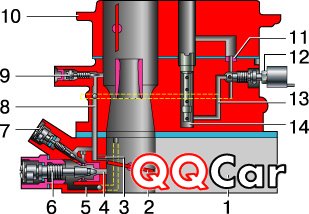

Before you start adjusting the idle speed of the VAZ 2106 carburetor, you should understand what it consists of this system. Below, you can find a schematic picture of the idle system and a transcript for it. Recall that in the previous article we considered placements, their scheme and description of each.

1. The body part of the throttle valves.

2. Chamber throttle valve No. 1.

3. Holes for transitions between operating modes.

4. Adjusting hole that determines the amount of mixture supplied.

5. A tubule used to deliver air into the system.

6. Screw responsible for adjusting the amount of mixture supplied.

7. Screw responsible for adjusting the quality of the supplied mixture.

8. Emulsion carburetor idle channel.

9. Screw for adjusting the level of supply of additional air.

10. Housing cover of the unit.

11. Air jet.

12. Body part of the jet of the fuel mixture.

13. The channel responsible for supplying the fuel mixture to the system.

14. Emulsion well.

How to adjust the idle speed of the VAZ 2106 with your own hands

Adjusting the idle speed of the carburetor of a VAZ 2106 car is a simple, but very responsible procedure. To perform it correctly and efficiently, you should use step by step instructions, which is presented below:

1. Using the quantity screw, set the engine speed to 900 rpm, based on the data displayed by the tachometer.

2. Turning the mixture quality screw will achieve a carbon monoxide concentration of 0.5 to 1.2 percent.

That's basically it, idle adjustment is complete.

But in the end, I would like to note a few important points:

The quantity screw rotates a maximum of 90 degrees;

- the quality screw rotates a maximum of 50 degrees;

- adjustment must be carried out with the obligatory use of a gas analyzer.

Under the hood of the "six"

Idling adjustment VAZ 2106 is designed for:

- restoration of proper engine operation, if idling is lost - maintaining stable crankshaft speed;

- adjusting the release of toxic substances and carbon dioxide into the atmosphere, minimizing these indicators.

The adjustment will eliminate excessive fuel consumption and allow the amount of CO 2 to be brought back to normal. At critical content harmful substances in the exhaust gases of the car, its operation is prohibited.

If the idling on the VAZ 2106 has disappeared, this may indicate the following problems:

- clogged idle fuel jet (XX);

- damaged solenoid valve, if it is installed on the jet XX;

- carburetor not adjusted.

The breakdown is accompanied by unstable operation of the motor at low speeds. It may stall after hard braking or while driving.

One of the elements of the carburetor on the VAZ 2106 is the idle fuel jet, which can be made with or without a solenoid valve. In the second case, a blank holder is installed instead of the EMC.

Troubleshooting carburetor problems

Regardless of whether the EMC is installed or not, the procedure for cleaning the idle fuel jet is the same.

- Unscrew the plug holder or EMC.

- Unscrew and remove the fuel jet XX.

- Clean the center channel of the jet.

In order to remove the XX jet from the radiator housing, you will need a 13 wrench, but depending on the design, a 14 wrench can also be used. After turning the EMC, remove the jet. If the center hole is clogged, clean it gently with fine wire or blow it with compressed air.

When the center channel of the fuel jet is clean, reinstall it. Screw it all the way in, carefully tighten with a wrench. Connect the "positive" wire to the EMC power terminal. Start the engine.

For the convenience of working with the carburetor, it is necessary to dismantle air filter. Turn on the ignition, before that, remove the power wire from the EMK terminal. Touch the supply wire to the valve terminal. A distinct click indicates that power is coming to the input of the EMC. In this case, the cause of the malfunction should be sought in the jet or in the carburetor itself. The absence of a click indicates that the malfunction is in the solenoid valve or in the fuse. To check the valve, connect the "plus" of the vehicle's battery to the EMC terminal, and the "minus" to its body. If there is no click, the solenoid valve is defective and must be replaced.

If the EMC input does not receive power, the reason may be a wiring fault or the need to replace the 8A fuse. If you have a regular fuse box, then this part is installed in the 9th cell.

If the fuse, wiring, and valve itself are OK, the cause bad work idling of a VAZ 2106 car may consist in clogging of the fuel jet XX. In this case, it must be cleaned.

Idle adjustment procedure

Carburetor device

To adjust the idle speed from the tools you only need a flat narrow screwdriver, preferably with a short handle. Idle speed adjustment should be carried out only on a warm engine. The valve timing and ignition clearances must be adjusted. If the adjustment is carried out on a cold motor, this will not bring the desired effect and it will not be possible to achieve stable performance.

The idle speed is adjusted by 2 adjusting screws: the 1st - the quality of the mixture and the 2nd - its quantity (Fig. 2). By default, at the factory, the adjusting screw 2 is supplied with a restrictive sleeve, which plays the role of a seal. Thus, the manufacturer indicates that the rotation of the screw lies in the factory range. For full adjustment and when it is not possible to adjust the idle speed, the restrictive sleeve is removed, the main adjustment is carried out.

- Screw 1 set the value of the crankshaft speed to 900 min. -one . They can be checked on a special stand or using a tachometer located on the instrument panel.

- With screw 2, it is necessary to achieve such a value of CO 2 that falls in the range of values from 0.5 to 1.2%. This will help special device- gasometer.

The rotation of the screw 2 contributes to a change in the speed of the crankshaft. In this case, we again adjust and set the value of the speed with screw 1 within 900 min. -one .

The correctness of the idle speed setting is checked by pressing the accelerator pedal and releasing it sharply. The crankshaft speed should increase smoothly and without failures, and then also decrease. The engine must not stall. If this happens or jerks are observed when pressing the gas pedal, the setting must be repeated.

If your car starts to stall at idle, then the fuel filter needs to be properly adjusted or cleaned.

Adjustment

To adjust the idle speed from the tools you only need a flat narrow screwdriver, preferably with a short handle. Idle speed adjustment should be carried out only on a warm engine. The valve timing and ignition clearances must be adjusted. If the adjustment is carried out on a cold motor, this will not bring the desired effect and it will not be possible to achieve stable performance.

The idle speed is adjusted by 2 adjusting screws: the 1st - the quality of the mixture and the 2nd - its quantity (Fig. 2). By default, at the factory, the adjusting screw 2 is supplied with a restrictive sleeve, which plays the role of a seal. Thus, the manufacturer indicates that the rotation of the screw lies in the factory range. For full adjustment and when it is not possible to adjust the idle speed, the restrictive sleeve is removed, the main adjustment is carried out.

Screw 1 set the value of the crankshaft speed to 900 min.-1. They can be checked on a special stand or using a tachometer located on the instrument panel.

With screw 2, it is necessary to achieve such a value of CO2 that falls in the range of values from 0.5 to 1.2%. This will help a special device - a gasometer.

The rotation of the screw 2 contributes to a change in the speed of the crankshaft. In this case, we again adjust and set the value of the speed with screw 1 within 900 min.-1.

The correctness of the idle speed setting is checked by pressing the accelerator pedal and releasing it sharply. The crankshaft speed should increase smoothly and without failures, and then also decrease. The engine must not stall. If this happens or jerks are observed when pressing the gas pedal, the setting must be repeated.

gone

I had this too, I had to wash it thoroughly. lower part carburetor, check and, if necessary, replace the needle valve and adjust the position of the float. Especially check the idle jet with back side carburetor opposite the valve cover.

Check the condition of the contacts, the integrity of the central high-voltage wire and the resistance of the slider. the ELHH valve on the Azon carburetor may be faulty; the tube may have torn or fallen off. carburetor failure is also possible.

How to setup

To solve the problem of how to adjust the idle speed on the VAZ 2106, you need to stock up on a set of driving tools, although for this technological operation one screwdriver is enough. On the Internet, you can watch the “idling VAZ 2106” video clip on the adjustment work to stabilize the idling of the vehicle.

To adjust the idle speed of the "six" carburetor, a number of preparatory conditions must be observed. These include:

The operation is carried out only on a motor that has reached operating temperature(about 90 degrees Celsius).

The gaps of the timing valves and ignition contacts (with a contact system) must correspond to the required dimensions.

When adjusting the idle speed of the VAZ 2106 carburetor on a cold engine, the desired result cannot be achieved. If there is no idling, then it will appear only if right conditions adjustments.

If the VAZ "sixth model" stalls at idle, then to find out how to adjust the idle, you must use the following algorithm:

The process of adjusting the idle speed on a VAZ 2106 car is carried out with two adjustment screws, the first is the quality screw, the second is the amount of the mixture.

In accordance with the factory settings, the quantitative adjusting screw is locked with a sealed limiter sleeve. To make adjustments and when there is no idling on the VAZ 2106, the seal is removed and adjustment work is carried out.

With a high-quality screw, we achieve a value of 900 rpm, comparing the value with the readings of the tachometer.

Using the quantity screw, we set the value indicator using a gasometer carbon monoxide within 0.6-1.3 percent. The circular movement of the adjusting screw changes the number of rotations of the crankshaft of the power unit.

In this situation, we re-fix the required parameters of the crankshaft speed with the first screw. If everything is done correctly, then with a sharp pressure and lowering the accelerator pedal, the rotation value should remain stable.

With the correct execution of all operations, a smooth increase in engine speed should be observed and the unit should work stably.

Faults

There are three most common reasons for the disappearance of idling:

Clogging of the idle jet EMK;

EMC burnout;

Lack of EMC power.