Full maintenance of fire and security alarm systems. Maintenance of automatic fire alarms Maintenance of fire extinguishing and fire alarm systems

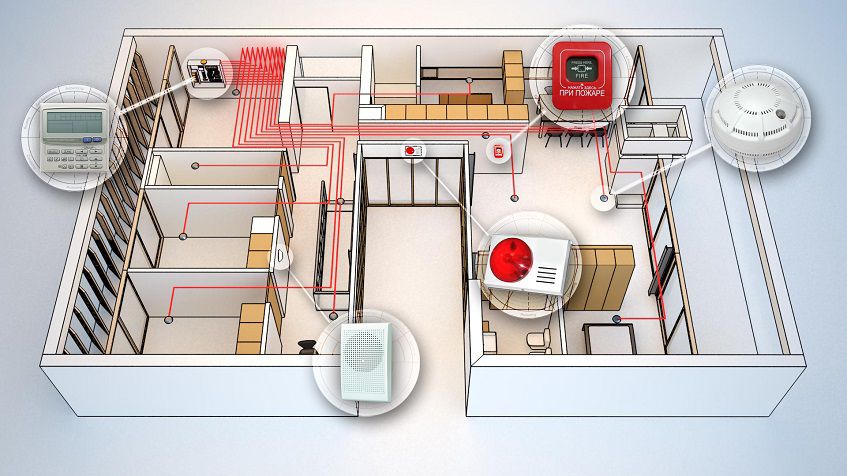

Maintenance (TO) of an automatic fire alarm (APS) is a set of measures to maintain its performance, regardless of external factors.

Timely and qualified service allows you to detect and eliminate possible equipment defects and eliminate alarm failure in case of fire. There are two types of automatic fire alarm service:

Planned.

Held once a month. A special log is kept, in which each visit of an employee of a service organization is strictly recorded. Scheduled maintenance is carried out in the scope of maintenance regulations (Regulations No. 1 and No. 2 will be discussed in detail below).

Unscheduled.

It is carried out in the event of a false alarm, equipment failure, external factors that can disable the system, as well as in response to customer complaints about the operation of individual elements of the equipment and the system as a whole. Unscheduled maintenance is also necessarily recorded in the routine maintenance log and is carried out in accordance with Regulation No. 2.

Fire alarm service is mandatory. After the installation of the equipment, the installer company transfers to the customer the operation manual and additional documentation (list of routine maintenance, fault log, contract with the service organization).

As a rule, the service contract is concluded with the company that carried out the installation of the equipment, but the customer may apply to another organization. A prerequisite is that the company conducting the maintenance service has a license from the Ministry of Emergency Situations. The requirements for the applicant for this license are quite high - this is a guarantee of the quality of the service provided.

FIRE ALARM MAINTENANCE REGULATIONS

The automatic fire alarm service regulation determines the mandatory procedure for the maintenance of automatic fire alarm systems (equipment check, visual inspection, sensor cleaning, operation test, etc.), as well as the frequency and scope of their implementation.

The regulation is necessarily included in the documentation transferred to the customer after the installation of the automatic fire alarm system. It is advisable for the customer to carefully study the regulations - this will allow you to control the fulfillment of obligations by the service organization.

Maintenance of automatic fire alarms is carried out according to Regulations No. 1 and No. 2:

Regulation No. 1 includes:

external inspection and verification of both individual elements of the alarm system and the system as a whole, elimination of identified shortcomings in the operation of equipment, prevention (cleaning sensors and other elements), checking the operability of the backup power source (measuring battery capacity).

Works within the framework of Regulation No. 1 are carried out at least once a month.

Regulation No. 2 contains:

the entire volume according to regulation No. 1 and additional work of a planned preventive nature. Regulation No. 2 is characterized by an extended scope - the equipment's noise immunity is checked, its main indicators are measured, and all automatic fire alarms are checked for compliance with the declared technical parameters.

Important: non-compliance with the regulations on the part of the organization performing the maintenance of fire systems is unacceptable!

REPAIR OF FIRE ALARM SYSTEMS

If equipment malfunctions are detected during scheduled or unscheduled maintenance of the APS, mandatory repairs are carried out. There are three types of automatic fire alarm repair:

- current;

- planned;

- capital.

Maintenance.

It is carried out to restore the functionality of the APS. Includes checking sensors (thermal, smoke, fire). Loops, cable paths and other electrical circuits are checked. All detected breaks are eliminated, faulty sensors are replaced with new ones. Current repairs are carried out at the request of the customer or when problems are identified during the maintenance process.

Scheduled preventive maintenance.

It is carried out to the extent necessary to eliminate all malfunctions identified during the operation of the fire alarm. Carrying out work ensures the normal functioning of the equipment (the sensors that have exhausted their resource are replaced, the backup batteries are changed, etc.).

The scope of work may vary depending on the design features of the equipment.

Capital repairs.

It is carried out after works on the reconstruction of objects, or after the exhaustion of the system resource. The overhaul is aimed at the complete restoration of serviceability and service life of the equipment. In the process of repair work, a complete replacement of the linear part (loops, cable lines, etc.) is carried out. The supply wiring and all sensors and devices are being changed.

After the overhaul is completed, the automatic fire alarm system is adjusted and tested. In general, the service life of the equipment reaches 10 years (depending on operating conditions).

Any of the above repairs is carried out by an organization that has the appropriate license from the Ministry of Emergency Situations!

DOCUMENTATION FOR MAINTENANCE AND REPAIR OF FIRE ALARMS

After the conclusion of the contract with the organization performing the maintenance of the fire alarm system, the customer keeps the documentation, including the log of work performed and the maintenance schedule.

Annual maintenance schedule is approved by the organization carrying out maintenance and is compiled taking into account the time spent on carrying out the required amount of work. The schedule indicates the date, the type of systems being serviced and the type of work performed (monthly and quarterly).

The schedule is filled in by an employee of the service organization and signed by the customer and contractor.

Completed work log service is approved by the service organization. The journal indicates the date of completion, the type of fire system and its elements, a description of the work performed and a conclusion on the technical condition. The replacement of APS components with the name is also fixed.

The magazine is filled in by the executor, the signature of the customer is obligatory. The log also records periodic safety briefings for employees.

Documentation issued after repair:

- Acceptance certificate - is drawn up after the repair. The act indicates a list of elements that were replaced during the repair, installation, adjustment work, and tests and tests carried out after the repair.

- List of mounted devices - indicates the name of the equipment, type, brand, serial number and quantity. The statement is certified by the signature of the representative of the service organization and the customer.

- Protocols for measurement of loop resistance.

Also, the documentation for the maintenance and repair of automatic fire alarms includes: an act of inspection of the fire alarm system, an act of technical re-examination, a log of false positives, tables, maps of loops and instructions for maintenance personnel.

All employees of a company or enterprise where an automatic fire alarm is installed should be familiar with the rules for its operation and general recommendations for fire safety.

By order of the head, responsible persons are appointed who monitor the performance of the system, and if malfunctions are detected (false alarms, etc.), they warn the management or independently fill out an application to the service organization.

* * *

© 2014-2020 All rights reserved.

The site materials are for informational purposes only and cannot be used as guidelines and normative documents.

On any of the objects must be carried out regularly. This is enshrined in regulatory documents, the main of which is the Decree of the Government of the Russian Federation under the number 390 and called "O". That is, the owner of the object must keep the alarm in good condition. A performance check should be carried out at least once a quarter. At the same time, the maintenance of the fire alarm (the regulatory documents confirm this in article number 63) is carried out strictly according to the drawn up schedule, which is based on the technical documentation from the manufacturer.

Anyone who ignores these requirements will be called to justice. Especially today, when the fire situation in the country has risen sharply. This is confirmed by large fires that occur with an enviable frequency, in which people die.

There is another regulatory document that defines liability for violations of fire safety. This is Federal Law number 69 "On Fire Safety". It clearly states who is responsible for non-compliance with the deadlines for the maintenance of the fire safety system. This:

- property owners;

- tenants;

- those responsible for the fire safety of the facility;

- officials, if their competence relates to fire safety.

What penalties can be applied according to regulatory documents:

- disciplinary: reprimand, remark, dismissal, dismissal;

- administrative: fines, suspension of activities, etc.;

- criminal.

Situations when managers or owners of facilities ignore the maintenance of fire alarms in accordance with regulatory documents are quite common. Especially at facilities that have recently been put into operation. It's just that everyone thinks that the warranty period and a well-conducted installation is a guarantee. But such an attitude is against the law. Therefore, the documentation for the maintenance of fire alarm systems is a document that must be carried out point by point strictly regardless of when the property was put into operation.

The fire alarm maintenance schedule is a document that determines the frequency of maintenance (TO). It is drawn up as an integral part of the contract between the company that operates the alarm system and the company that maintains the fire alarm network.

The schedule includes two documents:

- List of works (regular preventive) for each month during the year.

- Technological maps for each type of routine maintenance.

The Guidelines of 1999 are taken as the basis for creating the schedule. The title of the training manual: “Automatic fire extinguishing and fire alarm systems. Rules for acceptance and control. For obvious reasons, there are no technological maps in this document, because it is impossible to describe all types of equipment that are on the market today. Therefore, maps are developed on the basis of passports and maintenance instructions, which are an integral part of the instrument and equipment configuration.

Types of maintenance

If we talk about the fire alarm maintenance regulations, then there are two types:

- Monthly maintenance, it is TO-1. This includes a small list of works: external inspection, check for operation, briefing, checking special magazines, inspection of power supplies.

- Quarterly, aka TO-2. Here is a larger list of works: TO-1, checking how the detectors work, measuring power sources for their full charge, ringing the circuits for compliance with resistance, testing sensors, and so on.

There is a completely different fire alarm service regulation. It is associated with the verification of systems, which are determined according to their importance. In this case, TO-1 remains unchanged. But TO-2 is divided into two regulations:

- This is a comprehensive check that determines the performance of the system as a whole.

- This is a combination of TO-1 and TO-2, but several more types of regulatory work are added to them. Namely: purge detectors, check how reliable the fasteners are, inspect if the cables are sagging, and so on.

It should be noted that the last regulation of the two above is more convenient. Because the test can be carried out at the highest level. This will take more time, but guarantees an accurate determination of the technical condition. At the same time, the division by importance makes it possible to reduce the time of maintenance. For example, the entire system is divided into sections according to importance. That is, some are important, others are very important. The former can be serviced once a quarter, the latter monthly. And this does not contradict legislative documents related to the frequency of fire alarm maintenance.

Unscheduled maintenance

The fire alarm guidance documents (RD) do not contain a list of works related to unscheduled inspections. They are not regulated, because they are carried out only in emergency cases:

- the automation of the system worked falsely;

- after eliminating the causes of false alarm;

- if a signal came to the control panel that one of the detectors was dusty.

But the types of work carried out with this type of verification are the same and often correspond to both TO-1 and TO-2. Therefore, at many facilities, unscheduled inspections are included in the maintenance schedule.

How is the system health check performed?

The regulations for the maintenance of fire alarms should provide a sufficiently large volume of operations. It should include:

- checking all power sources: main and backup;

- the automation is checked both in the diagnostic mode and in the standby mode;

- fire detectors are checked for their quality work.

At the end of the work, an act is necessarily drawn up. There is no template for this document. Here it is important to enter all the results of the check and sign it by the members of the commission.

The Intellect Security company carries out maintenance of APS systems in accordance with all the rules and regulations (Automatic Fire Alarm) in Moscow and the Moscow region.

APS is located at a mass of enterprises. This is an effective set of technical means that helps protect people and property at the enterprise in situations where a fire breaks out. But over time, problems may arise in such a complex, repairs will be required. This is where many plant managers find it difficult because they don't know how to fix it and because the law requires that the APS be serviced on a regular basis. Detailed information on how the service is provided and what the letter of the law says is given below.

Maintenance of APS (2 regulations)

Basic maintenance of an automatic fire alarm system includes the following works:

- Testing the functionality of components.

- Component configuration, checking for compliance with legal norms, GOST.

- Working off the identified errors, as well as comments from the Ministry of Emergency Situations (in the event of an audit).

- Cleaning and diagnosing components.

Note: verification by the Ministry of Emergency Situations is mandatory for such complexes (see article 6.1 of the Federal Law-69 and Federal Law-123).

Maintenance of APS is provided on the basis of an agreement concluded between the Customer and the Contractor. The contract prescribes the regularity of such maintenance. In some cases, the regulations contain several types of maintenance (formally, several regulations are drawn up for each maintenance).

Often two regulations are drawn up for checking and repairing APS and SOUE:

- TO-1, calculated for each month:

- Checking components.

- Checking the memory for the operation of the complex.

- Reading logs for an object.

- Training of responsible employees.

- Evaluation of uninterruptible power supplies.

- Entering the required information in the logs of the company responsible for the maintenance of the APS.

- TO-2, calculated for each quarter:

- Carrying out TO-1.

- Checking the functioning of the components.

- Notification: checking, cleaning detectors.

- Replacing required items.

- Evaluation of the resistance of the loops (in this case, a special Act describing the results of the work carried out must be filled out).

- Updating the documentation on the actual performance of the complex.

- Measurement of the sound signal when alerting.

Maintenance of APS (3 regulations)

Unlike the option above, with this approach, the regulations are broken down and executed according to their degree of importance.

TO-1 similar to above.

TO-2 includes a check of the complex type, the purpose of which is to determine the correct functioning of the complex. As part of this, measurements of the power supply of the APS and other measures are carried out that help assess the performance of the complex and its components.

TO-3 includes the execution of TO-1 and TO-2, to which cleaning work for the PI is added, an assessment of the strength of the fasteners, an assessment of the degree of wiring prescription, and so on.

What is the advantage of the three regulations?

This approach creates the following benefits:

- The whole range of required measures is carried out, which significantly improves the quality of functioning and excludes the possibility of a sudden malfunction in the complex.

- Professional technicians have plenty of time to perform detailed checks on each component.

- The test is divided into several parts. Each part is handled by a separate group of specialists.

The cost of maintenance of APS in Moscow

The cost of maintenance of APS systems will be different for different enterprises, since the cost formation rests on various factors. Only after studying them, the exact cost for services for the performance of work is compiled. The list of activities to be carried out, as well as the prices for their implementation, are written into the contract and agreed between the Customer and the Contractor.

Professional employees should be engaged in such events for the complex, as soon as they technically correctly perform the required checks, write conclusions and ensure the complex continues to function correctly, due to which the safety at the facility will not be affected.

Monthly Maintenance

Maintenance of automatic fire alarm systems every month includes:

- Assessment of the technical condition of fasteners, installation.

- Alarms, detectors, devices responsible for control: performance testing.

- Evaluation of the integrity and reliability of wiring, communication connectors and loops.

- Keeping a log of the checks carried out, faults found and fixed.

Quarterly Maintenance

Maintenance of the APS system for the quarter consists of:

- Cleaning the lens and body parts of camera lenses from dirt.

- Assessment of the location of the cameras, adjustments to the location, if required.

- Testing of the protective shell for cameras of a special type (checking thermal and moisture protection characteristics).

- Testing electronic type modules for correct operation.

- Installation of new components to replace damaged ones.

What's Included in the Semi-Annual Maintenance

Carrying out maintenance of the APS during 6 months includes:

- Video server testing.

- System time check.

- Search for errors in data arrays.

- Configuration setting.

- Assessment of software performance.

- Troubleshooting.

- Video server cooling.

What's included in the annual service

Maintenance of the automatic fire alarm system for the year consists of:

- Testing the capacity of chargers.

- Measurement of voltage readings coming from uninterruptible power supplies.

- Analysis of the problems that arose during the year, as well as the measures taken to eliminate them.

Benefits of servicing APS with Intellect Security

Benefits provided to clients:

- Professional and friendly employees who perform their work on time and always answer customer questions.

- APS maintenance licenses.

- Availability of repair parts in our own warehouse.

- Prompt elimination of remarks of the Ministry of Emergency Situations.

- Prices that don't bite.

- Work strictly according to the agreed TOR.

This is information that you need to understand about carrying out repair and evaluation activities for complexes of this type. Preventive inspection of the complex, implementation of the required maintenance measures will lead to a properly functioning complex at the facility, which will allow organizing protective measures without errors. If the inspection of the complex is not carried out, the work will fail, due to which the evacuation of citizens will be difficult, life and health will be endangered. Such a negative scenario is unacceptable and punishable by law. In order to avoid such a development, it is recommended to conclude an agreement with a service company from the moment the complex appears at the facility.

One of the conditions for ensuring the safety of the facility is the regular maintenance of fire alarms.

It is designed to identify and promptly eliminate malfunctions in the operation of the system and thereby eliminate the likelihood of failure of the alarm system in the event of an emergency.

Cost Calculator

What happens?

Maintenance of fire alarm systems is divided into two large groups: scheduled and unscheduled. The first group includes all regulatory measures provided for in the technical documentation of the equipment manufacturer, as well as in the regulations for its operation at various facilities. These works include in particular:

- Checking the integrity of the loops;

- Control actuation of detectors;

- Checking SOUE (warning and evacuation control systems);

- Checking the charge level of the backup battery;

- Removing dust and dirt from appliances.

The second group of maintenance of fire alarms and warning systems includes all troubleshooting activities. As a rule, the cause of such work is the breakdowns of various origins that occurred during operation. The specificity of this service is the fact that the specialist needs to identify the cause of the malfunction and eliminate it, as well as take measures to eliminate such situations in the future.

Periodicity and documentation

Maintenance of fire and security alarm systems is carried out at regular intervals. In most cases, routine maintenance is carried out monthly and the timing of the check is indicated in the equipment documentation. However, operating conditions may lead to the need to reduce such frequency.

All maintenance activities are recorded in a special journal, where information is entered on the date and type of work performed, as well as the name and signature of the specialist who performed the maintenance. In case of replacement of any part or device as a whole, a corresponding note is made in the log.

In addition, once every five years, a detailed check of the OPS is carried out for further operation in terms of technical and economic efficiency. In the course of such a check, the degree of wear of the equipment, the level of moral obsolescence is established. Based on the results, an act is drawn up that allows you to operate the system further. The act may contain information on the need to replace individual technical means, the possibility of modernization, as well as the timing of the next such check.

The implementation of measures for unscheduled maintenance of fire alarms also requires documentary fixation. The work performed is also indicated in the OPS maintenance log, and a special act is drawn up for failed components. Large installation companies in Moscow, in such acts indicate not only the cause of equipment breakdown, but the possible circumstances of its occurrence. This information helps technicians predict possible future failure scenarios and, when performing system maintenance or upgrades, take action to eliminate or minimize such circumstances.

It should be remembered that in the event of an emergency at the facility, for example, a fire, the investigating authorities will require documents on the maintenance of fire protection systems without fail. Therefore, each owner of the facility must follow the maintenance documentation.

Who is conducting?

Only organizations licensed in this area can carry out a set of measures for the maintenance of fire alarms. Trained specialists have the right to carry out both preventive and repair work. At the same time, the owner is not relieved of the obligation to control the fire regime at the facility, including the serviceability of the fire alarm system. Any malfunction: false alarm, broken loops, etc. - This is an occasion to call a specialist for repairs. And in the event of a fire, if it is established that there is no request for repairs, all responsibility will fall solely on the owner of the facility, and the organization serving the alarm will be responsible only for the correct installation, and not for performance. The only exception is if less than a day has passed since the scheduled maintenance.

|

|

In the situation of a timely appeal to specialists and a subsequent emergency, the questions of the supervisory authorities will first of all be addressed to the service organization. Therefore, even the simplest fire alarm system needs regular maintenance by qualified personnel of a specialized organization.

PTM24 offers professional maintenance services for alarm systems for premises and facilities in Moscow and the Moscow region. Any complex structure needs maintenance with the participation of professionals. Without the necessary control, the equipment cannot be fully exploited. Thus, the issue is with the maintenance of the APS system (automatic fire system). Details of the current regulations for working with APS will be described in the presented article.

APS maintenance - goals and nuances

The facility needs a working fire protection system. We are talking about an alarm that notifies people about the start of a fire for evacuation. The presence of such a network guarantees the safety of employees and allows them to quickly take action to extinguish the fire.

Maintenance of the APS system occurs for two reasons:

- Maintenance of working condition, including carrying out inspections and repairs.

- Confirmation that the equipment is installed correctly and the alarm system works according to the norms.

Today there are two concepts that are often confused - APS and AUPS. The first term is a general concept and technically, it is wider.

For information! A detailed explanation is given in the layout of GOST 12.4.009-83. SSBT. AUPS is a set of technical means that are installed at the facility to protect against fire.

Maintenance of APS (2 regulations)

TO APS is serviced according to the regulations. The second regulation (TO-2) involves a quarterly inspection of the alarm. During such an inspection, the elements of the structure c are inspected, and the necessary repairs are carried out. Inspection of the fire alarm system is comprehensive, to confirm the operability of the system.

Maintenance of APS (3 regulations)

The third regulation is a more complete list of verification activities. Usually, the first and second regulations are also supplemented by cleaning the detectors, checking the integrity of the fasteners, and correcting cable sagging.

The cost of maintenance of APS in the company PTM24

| Number of pieces of equipment in the APS system | Cost per month in rubles |

|---|---|

| Up to 10 units | 1450 |

| 11 to 20 units | 2350 |

| 21 to 30 units | 3250 |

| 31 to 50 units | 3950 |

| From 51 to 100 units | 6950 |

| 101 to 200 units | 8550 |

| Additional value for every 50 units over 200 | from 890 |

APS examination prices |

|

| Primary fire alarm inspection | is free |

| Preparation of estimates for the maintenance of fire alarms | is free |

| Audit of the system in order to develop a strategy for its maintenance | is free |

| Comprehensive survey of the APS system | free of charge when concluding a maintenance contract |

The cost of APS maintenance in each case is determined individually, since it depends on the generality of factors.

Factors such as:

- Type of equipment.

- The structure of the system and the number of connected elements.

- The presence of breakdowns and the level of their complexity.

- The cost of the necessary parts.

As a result of determining the commonality of factors, the master performs standard calculations and announces the amount to the client. An official invoice is issued for payment.

Savings on preventive measures are regarded as negligence on the part of management and lead to a negative outcome. Contacting a dubious organization will not bring any benefit either. Therefore, saving and refusing technical inspection is not worth it, but it is better to take care of finding a reliable company in advance.