Vapor permeability of thermal insulation materials. Vapor permeability of building materials

Everyone knows that a comfortable temperature regime, and, accordingly, a favorable microclimate in the house is provided largely due to high-quality thermal insulation. Recently, there has been a lot of debate about what ideal thermal insulation should be and what characteristics it should have.

There are a number of properties of thermal insulation, the importance of which is beyond doubt: these are thermal conductivity, strength and environmental friendliness. It is quite obvious that effective thermal insulation must have a low coefficient of thermal conductivity, be strong and durable, and not contain substances harmful to humans and the environment.

However, there is one property of thermal insulation that raises a lot of questions - this is vapor permeability. Should the insulation be permeable to water vapor? Low vapor permeability - is it an advantage or a disadvantage?

Points for and against"

Supporters of cotton wool insulation claim that high vapor permeability is a definite plus, vapor-permeable insulation will allow the walls of your house to "breathe", which will create a favorable microclimate in the room even in the absence of any additional ventilation system.

Adepts of penoplex and its analogues say: the insulation should work like a thermos, and not like a leaky "quilted jacket". In their defense, they make the following arguments:

1. Walls are not the "breathing organs" of the house at all. They perform a completely different function - they protect the house from environmental influences. The respiratory system for the house is the ventilation system, as well as, in part, windows and doorways.

In many European countries, supply and exhaust ventilation is installed without fail in any residential area and is perceived as the same norm as a centralized heating system in our country.

2. The penetration of water vapor through walls is a natural physical process. But at the same time, the amount of this penetrating steam in a residential area with normal operation is so small that it can be ignored (from 0.2 to 3% * depending on the presence / absence of a ventilation system and its effectiveness).

* Pogozhelsky J.A., Kasperkevich K. Thermal protection of multi-panel houses and energy saving, planned topic NF-34/00, (typescript), ITB library.

Thus, we see that high vapor permeability cannot act as a cultivated advantage when choosing a thermal insulation material. Now let's try to find out if this property can be considered a disadvantage?

Why is the high vapor permeability of the insulation dangerous?

In winter, at sub-zero temperatures outside the house, the dew point (the conditions under which water vapor reaches saturation and condenses) should be in the insulation (extruded polystyrene foam is taken as an example).

Fig. 1 Dew point in XPS slabs in houses with insulation cladding

Fig. 2 Dew point in XPS slabs in frame-type houses

It turns out that if the thermal insulation has a high vapor permeability, then condensate can accumulate in it. Now let's find out why the condensate in the heater is dangerous?

Firstly, when condensation forms in the insulation, it becomes wet. Accordingly, its thermal insulation characteristics decrease and, conversely, thermal conductivity increases. Thus, the insulation begins to perform the opposite function - to remove heat from the room.

A well-known expert in the field of thermal physics, Doctor of Technical Sciences, Professor, K.F. Fokin concludes: “Hygienists consider the air permeability of fences as a positive quality that provides natural ventilation of the premises. But from a thermotechnical point of view, the air permeability of fences is rather a negative quality, since in winter time infiltration (air movement from inside to outside) causes additional heat loss by fences and cooling of rooms, and exfiltration (air movement from outside to inside) can adversely affect the humidity regime of external fences. promoting moisture condensation.

In addition, in SP 23-02-2003 "Thermal protection of buildings", section No. 8, it is indicated that the air permeability of enclosing structures for residential buildings should be no more than 0.5 kg / (m²∙h).

Secondly, due to wetting, the heat insulator becomes heavier. If we are dealing with a cotton insulation, then it sags, and cold bridges form. In addition, the load on the supporting structures increases. After several cycles: frost - thaw, such a heater begins to collapse. To protect the moisture-permeable insulation from getting wet, it is covered with special films. A paradox arises: the insulation breathes, but it needs protection with polyethylene or a special membrane that negates all its “breathing”.

Neither polyethylene nor the membrane allows water molecules to pass into the insulation. It is known from a school physics course that air molecules (nitrogen, oxygen, carbon dioxide) are larger than a water molecule. Accordingly, air is also unable to pass through such protective films. As a result, we get a room with a breathable insulation, but covered with an airtight film - a kind of greenhouse made of polyethylene.

To create a climate favorable for living in a house, it is necessary to take into account the properties of the materials used. Particular attention should be paid to vapor permeability. This term refers to the ability of materials to pass vapor. Thanks to knowledge of vapor permeability, you can choose the right materials to create a house.

Equipment for determining the degree of permeability

Professional builders have specialized equipment that allows you to accurately determine the vapor permeability of a particular building material. The following equipment is used to calculate the described parameter:

- scales, the error of which is minimal;

- vessels and bowls necessary for conducting experiments;

- tools that allow you to accurately determine the thickness of the layers of building materials.

Thanks to such tools, the described characteristic is precisely determined. But the data on the results of the experiments are listed in the tables, so when creating a project at home, it is not necessary to determine the vapor permeability of materials.

What you need to know

Many are familiar with the opinion that "breathing" walls are beneficial for those living in the house. The following materials have high rates of vapor permeability:

- wood;

- expanded clay;

- cellular concrete.

It is worth noting that walls made of brick or concrete also have vapor permeability, but this figure is lower. During the accumulation of steam in the house, it is removed not only through the hood and windows, but also through the walls. That is why many believe that it is “hard” to breathe in buildings made of concrete and brick.

But it is worth noting that in modern homes, most of the steam leaves through the windows and the hood. At the same time, only about 5 percent of the steam escapes through the walls. It is important to know that in windy weather, heat leaves the building made of breathable building materials faster. That is why during the construction of a house, other factors that affect the preservation of the microclimate in the room should be taken into account.

It is worth remembering that the higher the vapor permeability coefficient, the more moisture the walls contain. The frost resistance of a building material with a high degree of permeability is low. When different building materials get wet, the vapor permeability index can increase up to 5 times. That is why it is necessary to competently fix the vapor barrier materials.

Influence of vapor permeability on other characteristics

It is worth noting that if no insulation was installed during construction, in severe frost in windy weather, heat from the rooms will leave quickly enough. That is why it is necessary to properly insulate the walls.

At the same time, the durability of walls with high permeability is lower. This is due to the fact that when steam enters the building material, moisture begins to solidify under the influence of low temperature. This leads to the gradual destruction of the walls. That is why, when choosing a building material with a high degree of permeability, it is necessary to correctly install a vapor barrier and heat-insulating layer. To find out the vapor permeability of materials, it is worth using a table in which all values \u200b\u200bare indicated.

Vapor permeability and wall insulation

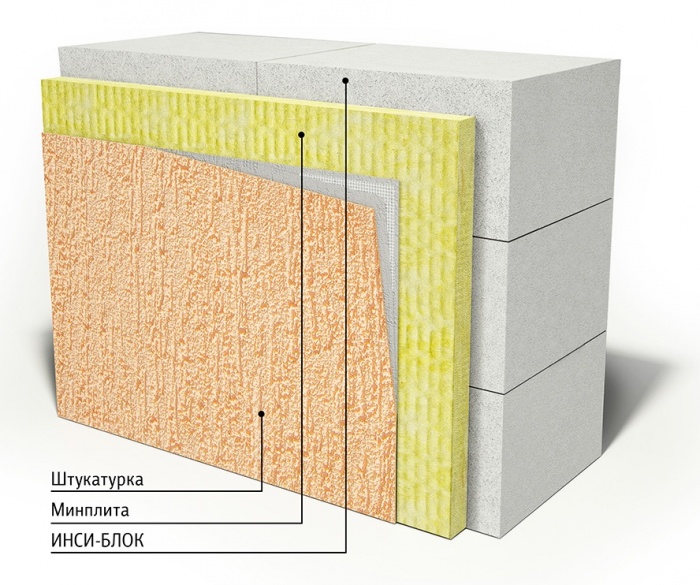

During the insulation of the house, it is necessary to follow the rule according to which the vapor transparency of the layers should increase outward. Thanks to this, in winter there will be no accumulation of water in the layers if condensate begins to accumulate at the dew point.

It is worth insulating from the inside, although many builders recommend fixing heat and vapor barrier from the outside. This is due to the fact that steam penetrates from the room and when the walls are insulated from the inside, moisture will not enter the building material. Extruded polystyrene foam is often used for internal insulation of a house. The vapor permeability coefficient of such a building material is low.

Another way to insulate is to separate the layers with a vapor barrier. You can also use a material that does not let steam through. An example is the insulation of walls with foam glass. Despite the fact that the brick is able to absorb moisture, foam glass prevents the penetration of steam. In this case, the brick wall will serve as a moisture accumulator and, during fluctuations in the level of humidity, will become a regulator of the internal climate of the premises.

It is worth remembering that if the walls are not properly insulated, building materials may lose their properties after a short period of time. That is why it is important to know not only about the qualities of the components used, but also about the technology for fixing them on the walls of the house.

What determines the choice of insulation

Often homeowners use mineral wool for insulation. This material has a high degree of permeability. According to international standards, the vapor permeability resistance is 1. This means that mineral wool practically does not differ from air in this respect.

This is what many manufacturers of mineral wool mention quite often. You can often find a mention that when a brick wall is insulated with mineral wool, its permeability will not decrease. It really is. But it is worth noting that not a single material from which the walls are made is capable of removing such an amount of steam so that a normal level of humidity is maintained in the premises. It is also important to consider that many of the finishing materials that are used in the design of the walls in the rooms can completely isolate the space, without letting the steam out. Because of this, the vapor permeability of the wall is significantly reduced. That is why mineral wool has little effect on steam exchange.

Vapor permeability - the ability of a material to pass or retain steam as a result of the difference in the partial pressure of water vapor at the same atmospheric pressure on both sides of the material. Vapor permeability is characterized by the value of the coefficient of vapor permeability or the value of the permeability resistance coefficient when exposed to water vapor. The vapor permeability coefficient is measured in mg/(m h Pa).

Air always contains some amount of water vapor, and warm air always has more than cold air. At an internal air temperature of 20 °C and a relative humidity of 55%, the air contains 8 g of water vapor per 1 kg of dry air, which create a partial pressure of 1238 Pa. At a temperature of -10°C and a relative humidity of 83%, the air contains about 1 g of steam per 1 kg of dry air, which creates a partial pressure of 216 Pa. Due to the difference in partial pressures between indoor and outdoor air, a constant diffusion of water vapor from the warm room to the outside occurs through the wall. As a result, under real operating conditions, the material in the structures is in a slightly moistened state. The degree of moisture content of the material depends on the temperature and humidity conditions outside and inside the fence. The change in the thermal conductivity coefficient of the material in the structures in operation is taken into account by the thermal conductivity coefficients λ(A) and λ(B), which depend on the humidity zone of the local climate and the humidity regime of the room.

As a result of the diffusion of water vapor in the thickness of the structure, moist air moves from the interior. Passing through the vapor-permeable structures of the fence, moisture evaporates to the outside. But if a layer of material is located near the outer surface of the wall that does not pass or poorly passes water vapor, then moisture begins to accumulate at the border of the vapor-tight layer, causing the structure to become damp. As a result, the thermal protection of a wet structure drops sharply, and it begins to freeze. in this case, it becomes necessary to install a vapor barrier layer on the warm side of the structure.

Everything seems to be relatively simple, but vapor permeability is often remembered only in the context of the "breathability" of the walls. However, this is the cornerstone in choosing a heater! It must be approached very, very carefully! It is not uncommon for a homeowner to insulate a house based only on the heat resistance index, for example, a wooden house with foam plastic. As a result, he gets rotting walls, mold in all corners and blames the "non-environmental" insulation for this. As for foam, due to its low vapor permeability, it must be used wisely and think very carefully whether it suits you. It is for this indicator that often wadded or any other porous heaters are better suited for insulating walls from the outside. In addition, with cotton wool heaters it is more difficult to make a mistake. However, concrete or brick houses can be safely insulated with polystyrene - in this case, the foam "breathes" better than the wall!

The table below shows materials from the TCH list, the vapor permeability index is the last column μ.

How to understand what vapor permeability is, and why it is needed. Many have heard, and some actively use the term "breathable walls" - and so, such walls are called "breathable" because they are able to pass air and water vapor through themselves. Some materials (for example, expanded clay, wood, all wool insulation) pass steam well, and some very poorly (brick, foam plastics, concrete). The steam exhaled by a person, released during cooking or taking a bath, if there is no exhaust hood in the house, creates increased humidity. A sign of this is the appearance of condensation on windows or pipes with cold water. It is believed that if the wall has a high vapor permeability, then it is easy to breathe in the house. In fact, this is not entirely true!

In a modern house, even if the walls are made of "breathable" material, 96% of the steam is removed from the premises through the hood and window, and only 4% through the walls. If vinyl or non-woven wallpaper is pasted on the walls, then the walls do not let moisture through. And if the walls are really "breathing", that is, without wallpaper and other vapor barrier, in windy weather heat blows out of the house. The higher the vapor permeability of a structural material (foam concrete, aerated concrete and other warm concrete), the more moisture it can absorb, and as a result, it has a lower frost resistance. Steam, leaving the house through the wall, at the "dew point" turns into water. The thermal conductivity of a damp gas block increases many times, that is, it will be very cold in the house, to put it mildly. But the worst thing is that when the temperature drops at night, the dew point shifts inside the wall, and the condensate in the wall freezes. When water freezes, it expands and partially destroys the structure of the material. Several hundred such cycles lead to the complete destruction of the material. Therefore, the vapor permeability of building materials can do you a disservice.

About the harm of increased vapor permeability on the Internet walks from site to site. I will not publish its content on my website due to some disagreement with the authors, but I would like to voice selected points. So, for example, a well-known manufacturer of mineral insulation, Isover, on its English site outlined the "golden rules of insulation" ( What are the golden rules of insulation?) from 4 points:

Effective isolation. Use materials with high thermal resistance (low thermal conductivity). A self-evident point that does not require special comments.

Tightness. Good tightness is a prerequisite for an effective thermal insulation system! Leaky thermal insulation, regardless of its coefficient of thermal insulation, can increase energy consumption from 7 to 11% for heating a building. Therefore, the tightness of the building should be considered at the design stage. And at the end of the work, check the building for tightness.

Controlled ventilation. The task of removing excess moisture and steam is assigned to ventilation. Ventilation should not and cannot be carried out due to a violation of the tightness of the enclosing structures!

Quality installation. On this point, I think, too, there is no need to speak.

It is important to note that Isover does not produce any foam insulation, they deal exclusively with mineral wool insulation, i.e. products with the highest vapor permeability! This really makes you think: how is it, it seems that vapor permeability is necessary to remove moisture, and manufacturers recommend complete tightness!

The point here is the misunderstanding of this term. The vapor permeability of materials is not designed to remove moisture from the living space - vapor permeability is needed to remove moisture from the insulation! The fact is that any porous insulation is not, in fact, the insulation itself, it only creates a structure that holds the true insulation - air - in a closed volume and, if possible, motionless. If such an unfavorable condition suddenly forms that the dew point is in a vapor-permeable insulation, then moisture will condense in it. This moisture in the heater is not taken from the room! The air itself always contains some amount of moisture, and it is this natural moisture that poses a threat to the insulation. Here, in order to remove this moisture to the outside, it is necessary that after the insulation there are layers with no less vapor permeability.

A family of four per day on average releases steam equal to 12 liters of water! This moisture from the indoor air must not get into the insulation in any way! What to do with this moisture - this should not bother the insulation in any way at all - its task is only to insulate!

Example 1

Let's look at the above with an example. Let's take two walls of a frame house of the same thickness and the same composition (from the inside to the outer layer), they will differ only in the type of insulation:

Drywall sheet (10mm) - OSB-3 (12mm) - Insulation (150mm) - OSB-3 (12mm) - ventilation gap (30mm) - wind protection - facade.

We will choose a heater with absolutely the same thermal conductivity - 0.043 W / (m ° C), the main, tenfold difference between them is only in vapor permeability:

Expanded polystyrene PSB-S-25.

Density ρ= 12 kg/m³.

Vapor permeability coefficient μ= 0.035 mg/(m h Pa)

Coef. thermal conductivity in climatic conditions B (the worst indicator) λ (B) \u003d 0.043 W / (m ° C).

Density ρ= 35 kg/m³.

Vapor permeability coefficient μ= 0.3 mg/(m h Pa)

Of course, I also use exactly the same calculation conditions: inside temperature +18°C, humidity 55%, outside temperature -10°C, humidity 84%.

I did the calculation in thermotechnical calculator By clicking on the photo, you will go directly to the calculation page:

As can be seen from the calculation, the thermal resistance of both walls is exactly the same (R = 3.89), and even their dew point is almost the same in the thickness of the insulation, however, due to the high vapor permeability, moisture will condense in the wall with ecowool, greatly moistening the insulation. No matter how good dry ecowool is, raw ecowool keeps heat much worse. And if we assume that the temperature outside drops to -25 ° C, then the condensation zone will be almost 2/3 of the insulation. Such a wall does not meet the standards for protection against waterlogging! With expanded polystyrene, the situation is fundamentally different because the air in it is in closed cells, it simply has nowhere to get enough moisture for dew to fall.

In fairness, it must be said that ecowool is not laid without vapor barrier films! And if you add a vapor barrier film between OSB and ecowool on the inside of the room to the "wall cake", then the condensation zone will practically come out of the insulation and the structure will fully meet the requirements for moisture (see picture on the left). However, the vaporization device practically makes it meaningless to think about the benefits of the “wall breathing” effect for the microclimate of the room. The vapor barrier membrane has a vapor permeability coefficient of about 0.1 mg / (m h Pa), and sometimes they are vapor barrier with polyethylene films or insulation with a foil side - their vapor permeability coefficient tends to zero.

But low vapor permeability is also far from always good! When insulating fairly well vapor-permeable walls made of gas-foam concrete with extruded polystyrene foam without vapor barrier, mold will certainly settle in the house from the inside, the walls will be damp, and the air will not be fresh at all. And even regular airing will not be able to dry such a house! Let's simulate a situation opposite to the previous one!

Example 2

The wall this time will consist of the following elements:

Aerated concrete brand D500 (200mm) - Insulation (100mm) - ventilation gap (30mm) - wind protection - facade.

We will choose the insulation exactly the same, and moreover, we will make the wall with exactly the same heat resistance (R = 3.89).

As you can see, with completely equal thermal characteristics, we can get radically opposite results from insulation with the same materials !!! It should be noted that in the second example, both designs meet the standards for protection against waterlogging, despite the fact that the condensation zone enters the gas silicate. This effect is due to the fact that the plane of maximum moisture enters the expanded polystyrene, and due to its low vapor permeability, moisture does not condense in it.

The issue of vapor permeability needs to be thoroughly understood even before you decide how and with what you will insulate your house!

puff walls

In a modern house, the requirements for thermal insulation of walls are so high that a homogeneous wall is no longer able to meet them. Agree, with the requirement for heat resistance R = 3, making a homogeneous brick wall with a thickness of 135 cm is not an option! Modern walls are multilayer structures, where there are layers that act as thermal insulation, structural layers, an exterior finish layer, an interior finish layer, layers of vapor-hydro-wind-insulation. Due to the different characteristics of each layer, it is very important to position them correctly! The basic rule in the arrangement of the layers of the wall structure is as follows:

The vapor permeability of the inner layer must be lower than the outer one, for free steam to escape the walls of the house. With this solution, the "dew point" moves to the outer side of the load-bearing wall and does not destroy the walls of the building. To prevent condensation inside the building envelope, the resistance to heat transfer in the wall should decrease, and the resistance to vapor penetration should increase from outside to inside.

I think this needs to be illustrated for better understanding.

Extruded or extruded polystyrene foam (EPS, EPPS, XPS), styrofoam (PSV / EPS) and polystyrene (PSB-S, expanded polystyrene, styrofoam) are widely used in Russia as a heat-insulating material (insulation). Unfortunately, manufacturers are often silent about the fact that due to the lack of vapor permeability, these materials can lead to the appearance of fungi and mold. This is especially true of non-vapor-permeable extruded polystyrene foam, which, for this reason, is not recommended for insulating brick and concrete walls.

But recently I came across a premium cottage village near St. Petersburg, which used imported materials, including Belgian brick and Neopor expanded polystyrene insulation. I was shocked that such houses were called eco-houses. A passive house using 400 mm of brickwork, as well as 350 mm of Neopor insulation (Neopor) on the walls, 300 mm of extruded polystyrene foam under the foundation slab, 400 mm of Neopor insulation (Neopor) on the floor slabs in a run - this is of course excellent. Moreover, a very small number of houses correspond to the German Passive House standard in Russia. But Ecohouse...

In addition, the choice of expanded polystyrene, albeit from the German manufacturer BASF, as a heater seemed strange. It is possible that this is a desire to make everything according to Western tracing paper and Western materials. But it seems to me much more reasonable to use brick (foam glass chips) or.

It turned out that Neopor (Neopor) is a new generation of expanding polystyrene foam (EPS) from BASF. In the Russian-language brochures "Neopor Wall Insulation (BASF)" and "Neopor. Expanding Polystyrene (EPS). Innovative AI Insulation.", unfortunately, information on the vapor transmission of this material is completely missing. The entire emphasis is on black graphite granules, which make it possible to reduce the thickness of the insulation by 15 percent, while maintaining the coefficient of thermal conductivity.

Information about Neopor on the BASF website in Russian is generally scarce. But in English you can find more interesting things. For example, the following:

Water and Neopor are good friends.Neopor Rigid Thermal Insulation is a closed-cell foam, but not all closed-cell foams are created equally. Neopor Rigid Thermal has a Class III Vapor Permeability rating of between 2.5 and 5.5 depending on thickness and density. This means walls constructed with Neopor as Continuous Insulation can more easily transport water vapor, reducing the likelihood of mold, mildew and structural damage. And, Neopor Rigid Thermal Insulation has low water absorption relative to traditional insulation materials.

I'll try to translate:

Water and Neopor are good friends.Neopor solid insulation is a closed cell foam, but not all closed cells are made the same. Neopor Rigid Thermal has a class 3 vapor permeability ranging from 2.5 to 5.5, depending on thickness and density. This means that walls built with Neopor as continuous insulation can easily transport steam, reducing the chance of mold, downy mildew, and structural damage. Solid Neopor insulation has less water absorption than traditional insulation materials.

In Russian sources, I came across information that the vapor permeability of Neopor is at least 0.05 mg / (m.h.Pa). But I'm not sure that these data can be trusted. Concrete has less vapor permeability. But the brick already has more, and it differs greatly from what kind of brick. So everything is correctly indicated about reducing the likelihood of fungi and mold. If we already use extruded polystyrene foam, styrofoam or polystyrene for insulating stone walls, then it is precisely such vapor-permeable (i.e., extruded polystyrene foam immediately disappears). Although environmentally friendly, non-flammable and durable - foam glass chips and vermiculite - even with vapor permeability, everything is much better. In any case, in addition to environmental friendliness, pay attention to the fact that the durability of the insulation corresponds to the durability of the walls of the house, and the vapor permeability of the insulation is at the level of the vapor permeability of the walls or higher.

Of course, the problem with heaters that do not remove steam can be solved with the help of forced ventilation, as well as with the help of interior decoration that blocks the passage of steam. But is it worth it to do so, you decide. Moreover, with such a struggle with the cause, there is always a chance that something will go wrong, including due to the mistake of finishers or equipment breakdown.

In general, be careful when you read marketing brochures, even if it's in the premium segment. Beautiful pictures and imported materials are not yet a guarantee of quality and environmental friendliness. Of course, for 60 million rubles, in the case of Wright Park, a cottage is obtained with very interesting solutions and high-quality materials. But for that kind of money, I would still avoid solutions like this one from Active House LLC.

We supply building materials to the cities: Moscow, St. Petersburg, Novosibirsk, Nizhny Novgorod, Kazan, Samara, Omsk, Chelyabinsk, Rostov-on-Don, Ufa, Perm, Volgograd, Krasnoyarsk, Voronezh, Saratov, Krasnodar, Tolyatti, Izhevsk, Yaroslavl , Ulyanovsk, Barnaul, Irkutsk, Khabarovsk, Tyumen, Vladivostok, Novokuznetsk, Orenburg, Kemerovo, Naberezhnye Chelny, Ryazan, Tomsk, Penza, Astrakhan, Lipetsk, Tula, Kirov, Cheboksary, Kursk, Tver, Magnitogorsk, Bryansk, Ivanovo, Ulan- Ude, Nizhny Tagil, Stavropol, Surgut, Kamensk-Uralsky, Serov, Pervouralsk, Revda, Komsomolsk-on-Amur, Abakan, etc.

08-03-2013

30-10-2012

The volume of wine production in the world in 2012 should fall by 6.1 percent due to poor harvests in several countries at once,

What is vapor permeability

10-02-2013According to the code of rules for design and construction 23-101-2000, vapor permeability is the property of a material to pass air moisture under the influence of a difference (difference) in the partial pressures of water vapor in air on the inner and outer surfaces of the material layer. The air pressures on both sides of the material layer are the same. The density of the stationary flow of water vapor G n (mg / m 2 h), passing under isothermal conditions through a layer of material 5 (m) thick in the direction of decreasing absolute air humidity, is G n \u003d cLr p / 5, where c (mg / m h Pa ) is the coefficient of vapor permeability, Ap p (Pa) is the difference in partial pressures of water vapor in air at opposite surfaces of the material layer. The reciprocal of q is called the resistance to vapor permeation R n = 5 / c and refers not to the material, but to a layer of material with a thickness of 5.

Unlike air permeability, the term "vapor permeability" is an abstract property, and not a specific amount of water vapor flow, which is a terminological flaw in SP 23-101-2000. It would be more correct to call vapor permeability the value of the density of the stationary flow of water vapor G n through the layer of material.

If, in the presence of air pressure drops, the spatial transfer of water vapor is carried out by mass movements of the entire air together with water vapor (wind) and is estimated using the concept of air penetration, then in the absence of air pressure drops, there are no mass movements of air, and the spatial transfer of water vapor occurs by chaotic movement water molecules in still air in through channels in a porous material, that is, not by convection, but by diffusion.

Air is a mixture of molecules of nitrogen, oxygen, carbon dioxide, argon, water and other components with approximately the same average speeds equal to the speed of sound. Therefore, all air molecules diffuse (randomly move from one gas zone to another, continuously colliding with other molecules) at approximately the same speed. So the speed of movement of water molecules is comparable to the speed of movement of molecules of both nitrogen and oxygen. As a result, the European standard EN12086 uses the more precise term diffusion coefficient (which is numerically equal to 1.39ts) or diffusion resistance coefficient 0.72/ts instead of the vapor permeability coefficient ts.

Rice. 20. The principle of measuring the vapor permeability of building materials. 1 - glass cup with distilled water, 2 - glass cup with a drying agent (concentrated solution of magnesium nitrate), 3 - material under study, 4 - sealant (plasticine or paraffin with rosin), 5 - thermostatically sealed cabinet, 6 - thermometer, 7 - hygrometer.

The essence of the concept of vapor permeability explains the method for determining the numerical values of the vapor permeability coefficient GOST 25898-83. A glass cup with distilled water is hermetically covered with the tested sheet material, weighed and placed in a sealed cabinet located in a thermostated room (Fig. 20). An air dryer (a concentrated solution of magnesium nitrate, providing a relative air humidity of 54%) and devices for controlling temperature and relative air humidity (a thermograph and a hygrograph are desirable) are placed in the cabinet.

After a week of exposure, a cup of water is weighed, and the vapor permeability coefficient is calculated from the amount of evaporated (passed through the test material) water. The calculations take into account that the vapor permeability of the air itself (between the water surface and the sample) is 1 mg/m h Pa. The partial pressures of water vapor are taken equal to p p \u003d cpp, where p is the saturated vapor pressure at a given temperature, cp is the relative humidity of the air, equal to unity (100%) inside the cup above water and 0.54 (54%) in the cabinet above the material.

Data on vapor permeability are given in tables 4 and 5. Recall that the partial pressure of water vapor is the ratio of the number of water molecules in the air to the total number of molecules (nitrogen, oxygen, carbon dioxide, water, etc.) in the air, i.e. the relative number of water molecules in the air. The given values of the heat absorption coefficient (with a period of 24 hours) of the material in the structure are calculated by the formula s \u003d 0.27 (A, poCo) 0 "5, where A, ro and Co are tabular values \u200b\u200bof the coefficient of thermal conductivity, density and specific heat.

Table 5 Resistance to vapor permeability of sheet materials and thin layers of vapor barrier (Appendix 11 to SNiP P-3-79 *)

|

Material |

Layer thickness |

vapor permeation resistance, m/h Pa/mg |

|

|

Cardboard ordinary |

|||

|

Asbestos-cement sheets |

|||

|

Gypsum lining sheets (dry plaster) |

|||

|

Wood fiber sheets |

|||

|

Wood fiber sheets |

|||

|

Roofing glassine |

|||

|

Ruberoid |

|||

|

Tol roofing |

|||

|

Polyethylene film |

|||

|

Three-layer plywood |

|||

|

Painting with hot bitumen at once |

|||

|

Painting with hot bitumen for two times |

|||

|

Oil painting for two times with pre-filler and primer |

|||

|

Enamel paint |

|||

|

Covering with insulating mastic |

|||

|

Coating of butumno-cookersalt mask at a time |

|||

|

Coating of butumno-cookersalt mask twice |

|||

The conversion of pressures from atmospheres (atm) to pascals (Pa) and kilopascals (1kPa = 1000 Pa) is carried out taking into account the ratio 1 atm = 100,000 Pa. In bathing practice, it is much more convenient to characterize the content of water vapor in the air by the concept of absolute air humidity (equal to the mass of moisture in 1 m 3 of air), since it clearly shows how much water must be added to the heater (or evaporated in the steam generator). Absolute air humidity is equal to the product of relative humidity and saturated vapor density:

|

Temperature °С 0 |

||||||||||

|

Density saturated steam do, kg/m 3 0.005 |

||||||||||

|

Pressure rich steam ro, atm 0.006 |

||||||||||

|

Pressure saturated steam ro, kPa 0.6 |

||||||||||

Since the characteristic level of absolute air humidity in baths of 0.05 kg / m 3 corresponds to a partial pressure of water vapor of 7300 Pa, and the characteristic values of partial pressures of water vapor in the atmosphere (outdoors) are at 50% relative air humidity 1200 Pa in summer (20 °C) and 130 Pa in winter (-10°C), then the characteristic differences in partial pressures of water vapor on the walls of the baths reach values of 6000-7000 Pa. It follows that the typical levels of water vapor flows through the beam walls of baths with a thickness of 10 cm are (3-4) g / m 2 hour under conditions of complete calm, and calculated for 20 m 2 walls - (60-80) g / hour.

This is not so much, considering that a 10 m 3 bath contains about 500 g of water vapor. In any case, with the air permeability of the walls during strong (10 m / s) gusts of wind (1-10) kg / m 2 hour, the transfer of water vapor by the wind through the timber walls can reach (50-500) g / m 2 hour. All this means that the vapor permeability of the beamed walls and ceilings of the baths does not significantly reduce the moisture content of the wood soaked with hot dew during serving, so that the ceiling in the steam bath can actually get wet and work as a steam generator, mainly humidifying only the air in the bath, but only when careful protection of the ceiling from gusts of wind.

If the bath is cold, then the pressure drops of water vapor on the walls of the bath cannot exceed 1000 Pa in summer (at 100% humidity inside the wall and 60% humidity outside at 20 ° C). Therefore, the characteristic drying rate of timber walls in summer due to vapor permeability is at the level of 0.5 g / m 2 hour, and due to air permeability with a light wind of 1 m / s - (0.2-2) g / m 2 hour and with gusts of wind 10 m / s - (20-200) g / m 2 hour (although inside the walls the movement of air masses occurs at speeds of less than 1 mm / s). It is clear that the processes of vapor permeation become significant in the balance of moisture only with good wind protection of the walls of the building.

Thus, for quick drying of the building walls (for example, after emergency roof leaks), it is better to provide ventilation inside the walls (channels of a ventilated facade). So, if in a closed bath the inner surface of a timber wall is wetted with water in an amount of 1 kg / m 2, then such a wall, passing water vapor through itself to the outside, will dry out in the wind in a few days, but if the timber wall is plastered from the outside (that is, it is windproof), then it will dry out without heating in only a few months. Fortunately, wood is very slowly saturated with water, so water drops on the wall do not have time to penetrate deep into the wood, and such long drying of the walls is not typical.

But if the crown of the log house lies in a puddle on a plinth or on wet (and even damp) ground for weeks, then subsequent drying is possible only by wind through the cracks.

In everyday life (and even in professional construction), it is in the field of vapor barrier that there is the greatest number of misunderstandings, sometimes the most unexpected. So, for example, it is often believed that hot bath air allegedly "dries" the cold floor, and cold, dank air from the underground "absorbs" and allegedly "moistens" the floor, although everything happens just the opposite.

Or, for example, they seriously believe that thermal insulation (glass wool, expanded clay, etc.) “sucks” moisture and thereby “dries out” the walls, without wondering about the future fate of this supposedly endlessly “sucked up” moisture. It is useless to refute such everyday considerations and images in everyday life, if only because in the general public environment no one is seriously (and even more so during the “bath chatter”) in the nature of the phenomenon of vapor permeability is not interested.

But if the summer resident, having the appropriate technical education, really wants to figure out how and where water vapor penetrates into the walls and how they exit from there, then he will have, first of all, to evaluate the actual moisture content in the air in all areas of interest (inside and outside the bath ), moreover, objectively expressed in mass units or partial pressure, and then, using the data on air permeability and vapor permeability, determine how and where water vapor flows and whether they can condense in certain zones, taking into account real temperatures.

We will deal with these questions in the following sections. At the same time, we emphasize that for approximate estimates, the following characteristic values of pressure drops can be used:

Air pressure drops (to assess the transfer of water vapor together with air masses - by wind) range from (1-10) Pa (for one-story baths or weak winds 1 m / s), (10-100) Pa (for multi-storey buildings or moderate winds 10 m/s), more than 700 Pa during hurricanes;

Drops in partial pressures of water vapor in the air from 1000Pa (in residential premises) to 10000Pa (in baths).

In conclusion, we note that people often confuse the concepts of hygroscopicity and vapor permeability, although they have completely different physical meanings. Hygroscopic ("breathing") walls absorb water vapor from the air, converting water vapor into compact water in very small capillaries (pores), despite the fact that the partial pressure of water vapor can be lower than the saturation vapor pressure.

Vapor-permeable walls simply pass water vapor through themselves without condensation, but if in some part of the wall there is a cold zone in which the partial pressure of water vapor becomes higher than the pressure of saturated vapors, then condensation, of course, is possible in the same way as on any surfaces. At the same time, vapor-permeable hygroscopic walls are moistened more strongly than vapor-permeable non-hygroscopic ones.