How to assemble a hydrogen generator detailed instructions. Hydrogen boiler - ecological clean home heating

DIY hydrogen engine

Hydrogen Generators for Passenger Cars - DIY Hydrogen Generator

Do you want to make a hydrogen generator for a car? Thousands of people who are developing their own hydrogen generators are installing them on cars to run on water because of ever-increasing fuel prices. If you're one of the many people who are looking to save money, or are trying to find ways to cut costs, you've probably heard discussions about hydrogen for cars and how to build your own generator.

The first time I heard about hydrogen for cars a few months ago, and although I was very skeptical, I still decided to find out about it and did some research. simple installations are sold that help save from 30% to 50% of fuel

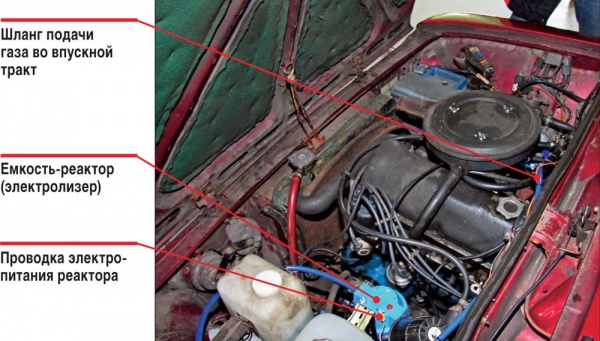

These hydrogen fuel cells for a car consist of a small container or vessel with water located under the hood, pour ordinary tap water into the vessel, throw in a teaspoon of catalyst, soda and dip a few stainless steel plates. We connect these plates to the battery and when the ignition is turned on, gas begins to be produced. We mount the hydrogen hose in the air duct after the filter.

Once all of this is set up correctly, hydrogen and oxygen (HHO) can be extracted from water using electrolysis (a process where electricity is used to break water molecules into HHO). . Hydrogen engine how to make an engine. This mixture of hydrogen and oxygen is then drawn into your car's intake manifold, where it mixes with regular gasoline from the fuel tank and burns in the engine as normal.

In this consistency of gasoline and HHO, combustion occurs more perfectly, which significantly improves the performance of the engine, so you save fuel. In some cases up to 50%. It also increases the power of your motor.

It turns out that making your own hydrogen generator in a car is not only quite easy, but also inexpensive. It cost us less than 100. There are a huge number of tutorials on the Web, if you want to see the details, write a hydrogen generator on YouTube. The supply of hydrogen bound in water is virtually inexhaustible. Breaking atomic bonds allows hydrogen to be created and then used as a fuel. Countless processes have been developed to decompose water into its constituent elements.

Do-it-yourself hydrogen plant for a car

Sold1er

All videos Advanced search By duration By date Order High-definition only Safe search Added 9 Uploaded 0 9 videos 02:52 PM The device is justified by a small amount of gas produced, and the use of a specific material with an admixture of titanium in the reactor. It is also shown that the device does not need a resonance generator, but m. Brown gas. (Hydrogen Generator) to test the production of hydrogen gas from ordinary water at home. The scope of implementation depends on your imagination and awareness.

Ne-Fi-R-Ti-Ti

Hydrogen generator-entry: Water is a compound of 2 parts of hydrogen and 1 oxygen atom. it is not difficult to replace the Skoda Fabia timing parts with your own hands, and in this article we will look at how the belt changes. This is the chemical sign of H 2 O, which indicates that any molecule is a combination of 1 oxygen atom and 2 hydrogen atoms. All atoms can create ions. Atoms tend to ionize when exposed to an electronic field. You can create, this is in experiments with the introduction of a Tesla coil. Hydrogen forms positive ions and oxygen forms negative ions. And we will use this to our advantage, using an electronic field to separate water molecules from each other.

Springfield

Read also

Hydrogen generators, which are currently used in cars to save energy, are of 2 types: wet cell and dry cell. Each of them has its own advantages and disadvantages, but the dry cell is the development of the second generation of devices that produce hydrogen for cars, because it eliminated significant shortcomings of the wet predecessor. When experimenting with hydrogen generation with your own hands, safety precautions should be observed as carefully as possible! It is necessary to first study the experience of other researchers and practitioners. Links to resources on this topic with practical examples at the end of the article. The video shows a diagram of a dry generator. More details on how to do it - on the second video. With your own hands, this is what a ready-made air suspension on a Mercedes Viano looks like. Detailed Description For the production of dry batteries, perforated stainless steel grade 316L or 316T is useful for you. Sheet thickness 0.4 mm, or 0.5 mm, not thicker, with a hole diameter of 2 mm, or 3 mm.

Masikk88

Overview of new cars, test drives. As well as a video on do-it-yourself repair and maintenance. New cars Testing cars Tuning Painting Soundproofing Repair Driving lessons Similar videos HYDROGEN generator ikona112211 My hydrogen generator version 2/1 Alexander Vudz Gas welding machine Prometheus, hydrogen, electrolyzer TAPOK na VPISKE Hydrogen fuel cell ChipiDip Hydrogen generator HNO - Installation on Dodge Ram engine displacement V5. 7 Fuel economy. MecoMclub HHO hydrogen generator (assembly), HHO Generator HYDROGEN (assembling) dembik71 Avarinone hydrogen generator high-voltage electrolysis efficiency 150% Dmitry Petrov Stanley Meyer cell (hydrogen generator) solenger Assembly of NHO hydrogen generator dembik71 Hydrogen engine.

wild black cat

Facebook Twitter My world Vkontakte Google Nowadays, it is virtually impossible to predict the price of fuel for cars at gas stations. The constant increase in the price of this raw material, very often leads the motorist to the idea of simply putting his own car in the garage for an indefinite time, and transfer to public transport. But not everyone thinks critically. It turns out that there are people in modern society who are not going to obey the laws of the economy, and find independent ways to solve the problem with the fuel resource. One of these solutions to the problem is the introduction of a hydrogen engine into the system of your own car. Craftsmen eclipsed all expectations and learned how to make hydrogen generators on their own, and this is fun.

Hydrogen powered car DIY

We assemble a hydrogen engine with our own hands. Here is an introductory video on assembling the generator for.

How to make a DIY hydrogen generator

Do-it-yourself hydrogen generator! how to do? From ordinary water it is possible by means of electronic influence.

ghy4ko

A hydrogen burner, as the name implies, works by using the heat released when hydrogen is burned. A gas mixture of hydrogen and oxygen (HHO - two molecules of hydrogen and one oxygen) is called explosive gas in our country, and Brown's gas in theirs. Hydrogen in combination with oxygen has the highest combustion temperature among gases - up to 2800 C. But hydrogen is very explosive. As, in general, any gas supplied in huge cylinders under the highest pressure. How to make a hydrogen generator with your own hands make a generator engine with your own hands. How to make wheel alignment. The camber-toe angles of the car's wheels can be adjusted with your own hands, using improvised means and simple devices. The advantage of hydrogen (or HHO gas) over other types lies in the ability to obtain it by electrolysis from ordinary water! At the same time, to create a hydrogen burner with our own hands, we do not need to accumulate hydrogen in any cylinders at all. How to remove and replace brake pads in Mitsubishi Lancer 9. If you decide to repair the brake pads in Mitsubishi Lancer 9 with your own hands, then you need to do this. Hydrogen electrolysis burner produces gas in the quantities needed for instantaneous combustion. This significantly increases the safety of gas welding or cutting using a hydrogen torch based on an electrolysis HHO generator.

Angel-379

Science understands only one completely clean fuel - this is hydrogen, which is used in the galactic industry. In the process of burning hydrogen, compounds with oxygen are formed, in other words, water. The reserves of this fuel are inexhaustible, because it is on a par with helium is the main building material in the universe. Now we will tell about hydrogen generators, which are gaining immense popularity in the near future due to affordable prices and environmental friendliness. Do-it-yourself hydrogen generators Distinctive features of hydrogen heating This type of heating is based on the generation of a lot of thermal energy as a result of the contact of oxygen and hydrogen molecules. Typically, the only by-product in this case is distilled water. And in order to put this principle into practice, a huge number of developments were carried out to create a hydrogen heating boiler (we are talking about industrial models).

Comment SourceCancel

Hydrogen engines for cars

Calling the lazy transition of car engines to other energy sources, to put it mildly, is wrong. How to make a hydrogen generator with your own hands .... But the trend is already set. At first, the Euro1 standard in the 90s of the last century, later, the increasingly narrowing limits of permissible emissions into the atmosphere. In fact, only very wealthy car manufacturers so far offer gasoline and diesel fuel as candidates. But it didn't start like that at all.

First hydrogen powered car

Since we are now talking about how to use hydrogen engines in cars, about the prospects for their occurrence on the conveyors of car factories in principle, it is simply impossible not to recall that such an engine appeared 75 years earlier than a gasoline unit. It was 1806, and the invention itself is attributed to the Franco-Swiss inventor de Rivaz. As you know, the gasoline engine was invented only by the end of the 19th century.

The hydrogen engine is designed to solve not only the economic problem of the constant rise in the price of petroleum products. In the end, oil will someday end and at that moment it will be too late to think about its candidacy. On the other hand, scientists are looking for a replacement for ordinary fuel for auto engines in the literal sense, in order to save civilization. The atmosphere of the planet is already oversaturated with nitrogen oxides, sulfur oxides, carbon dioxide. And with the growth in the number of personal vehicles, even in developing countries, the situation with the environmental indicators of the planet's atmosphere is close to critical.

What is a hydrogen engine

Two directions are now clearly outlined in which the designers of hydrogen vehicles are working.

- Trials are being made to train a conventional internal combustion engine to run on hydrogen.

- The introduction of fuel parts on hydrogen to produce electricity as an energy source.

Both of these areas are considered promising, and we can already talk about more or less effective experiments in this area.

Read also

For example, the Toyota Mirai works on the principle of a hybrid car. The only type of energy used is electricity. How to make wheel alignment with your own hands. But with all this, the electric motor is powered by both a nickel-metal hydride battery and a hydrogen fuel cell, the so-called chemical generator.

The principle of operation of the engine with a hydrogen generator

The mechanism of operation of a hydrogen car is not very complicated. Here is a schematic representation of the device and the principle of operation of the hydrogen unit.

- Oncoming air is supplied through grilles in the front panel and in the bumper.

- Air, or rather, oxygen, which is in the air, is supplied by a hydrogen generator.

- The generator produces electronic energy that is fed into the battery.

- Also, part of the energy goes to the operation of the electric motor.

- The electric motor turns the drive wheels through the drive system.

- Water, which is formed as a result of a chemical reaction, is connected from the car either automatically or at the command of the driver.

The mechanism of operation of the hydrogen generator is also simple. It is based on the chemical reaction of hydrogen and oxygen, as a result of the molecular interaction of which electronic energy is generated. Above we have a nice diagram showing how a hydrogen fuel cell works.

ICE on hydrogen?

The next direction in which inventors and designers are going is the use of an internal combustion engine, which would be able to work on a mixture of hydrogen and oxygen. There are more such developments. For example, Mazda, Ford, BMW and MAN have been improving the design of hydrogen cars for a couple of years. For the base, they took not an ordinary piston gasoline engine, but a rotary one. How to make a do-it-yourself gazelle wheel alignment. This is explained by the fact that the exhaust and intake manifolds are placed close enough to each other. How to make hydrogen send to the engine. Make your own generator. The exhaust manifold can reach very high temperatures, so there is a high possibility of fuel igniting outside the combustion chamber. The rotary engine is devoid of such a feature, therefore it is taken specifically as a base.

But the standard engine with a crank mechanism was also used as an experience on a BMW 7-series car. It was an engine that ran on both gasoline and hydrogen completely independently. The 12-cylinder six-liter engine showed a power of 260 forces, regardless of the type of fuel. The hydrogen consumption per hundred square meters was about 50 liters. The hydrogen tank provided a mileage of 200 km, after which it was possible to switch the engine to gasoline.

Disadvantages of hydrogen engines

The project failed. The fact is that even with small alterations in the design of the car, it was necessary to install a hydrogen tank, which occupied half the trunk. In addition, the infrastructure of hydrogen refueling in the world has a few points where you can refuel cars with hydrogen. It makes no sense to produce hydrogen with your own hands, the scale is not the same, and the filling equipment must be completely sealed.

Scientists predict a busier development of hydrogen filling infrastructure only by 2030, not earlier. How to replace the rear brake pads with your own hands? How to remove the brake drum on the Kia Picanto? Pure hydrogen can be obtained only in 2 ways - either by electrolysis, or by separating it from natural gas, since pure hydrogen does not exist in nature.

The prospect of making hydrogen from water looks intriguing, but investors are not in line to fund the construction of the equipment needed to produce volatile gas from ordinary water. Development continues, oil is slowly being completed, so the population of the earth should think about other types of fuel a little more actively, before it's too late. In the meantime, successful roads to all on our diesel and gasoline cars.

Source

Read also

vesko-trans.ru

Hydrogen engine - description, characteristics, equipment. DIY hydrogen engine for a car

Hydrogen car. Hydrogen generator for car

Sooner or later, oil reserves around the world will run out. Naturally, this is unlikely to happen tomorrow, but already today the prices of oil-based fuels have risen significantly. This fact has become a good incentive for developers who are engaged in the invention of the fuel of the future. In addition, it should be not just fuel, but, preferably, renewable fuel. Many people believe that a hydrogen car is a toy. Let's see if that's the case.

Fuel of the future

The well-known writer Jules Verne wrote about such fuel a long time ago in his adventure novels. In one of his novels on the topic of an alternative energy source, the writer said that ordinary water would become a product for energy. And so it happened. Yes, this is not fiction.

Water, or rather, one of its components - hydrogen - is not only the first chemical element. It is also the source of energy for the future. And imagine, this future is already very close.

Today, Japanese companies produce engines that run only on this type of fuel. Toyota's hydrogen car is the world's first mass-produced car equipped with this engine.

The car is a sedan with four doors. It has an electric motor with a capacity of 151 hp. with. You ask, what does hydrogen have to do with it, because the motor is electric? Let's figure it out.

Technologies "Toyota-Mirai"

The electric motor is powered by a special converter. And he already receives energy directly from hydrogen. The gas is contained in the car's tanks under high pressure. Tanks are made of carbon fibers.

But the reaction still needs oxygen. Yes it is. The car receives oxygen directly from the radiator while driving. One filling of two tanks with hydrogen will be enough to cover up to 480 km by car. Refueling only takes 3 minutes. During this time, 170 liters of gas will be poured into the tanks of the car. On average, a hydrogen-powered car will consume about 4.7 liters per 100 kilometers.

How it works?

When hydrogen reacts with oxygen, a violent chemical reaction occurs, during which electrical energy is generated. It is stored in the battery. The car is driven by a synchronous AC motor.

Technical characteristics of the "Japanese"

The maximum speed that a hydrogen car is capable of is 180 km / h. Up to 100 km, the car can accelerate in just 9 seconds.

In addition to the fact that you can ride a "Japanese" and not harm the environment, this car can also be used at home as a power plant. The engineers and designers who took part in the development of the novelty claim that with the help of such a system, current is supplied to the whole house. Thus, you can freely use free electricity for 5 days.

Fuel discounts for customers

Those residents of Japan and the United States who purchase a hydrogen car will receive big discounts and free refueling of their cars. The authors of the grandiose project are sure that they will succeed. However, other automakers are not sitting idly by. And soon, consumers can have a large selection of alternative fuel vehicles.

Great and terrible

The fact that hydrogen can become number 1 in matters of alternative fuels has been talked about for a long time. Even before the economic crisis back in 2008, the media was constantly printing reports about how wonderfully you can use the power of hydrogen.

Any hydrogen-powered car was considered a breakthrough, and its creators were erected almost into the face of saints. Unprepared readers and motorists confidently considered this a real breakthrough, but it must be said that this is not so.

150 years ago

The real state of affairs is slightly different from what is written in blogs dedicated to alternative energy. Hydrogen has been used in this capacity for about 150 years. The hydrogen car helped win the war.

The very first internal combustion engine using such fuel was built by Lenoir in 1860. Then, in 1942, there was a fairly massive transfer of all automotive technology to a hydrogen energy source.

It happened in besieged Leningrad. Initially, hydrogen was to be used in air defense systems for balloons. However, the great Russian engineers managed to change the situation.

How it was?

Airbuses were used to protect the city. These flying objects made of rubber, filled to the brim with hydrogen, made it impossible for the fascist planes to conduct aimed fire at the city.

However, rubber air protection had one huge disadvantage. Due to the fact that the shell of the airbus let this gas through, the airbuses were descending. Instead of hydrogen, various water vapors, as well as other gases, took its place. Therefore, sometimes airbuses were lowered to the ground, bled off and refueled again.

Winches and GAZ AA gasoline trucks were used to refuel the airbuses. And under the conditions of the blockade, gasoline was very expensive in Leningrad. The war depleted supplies, and Boris Shelits, who was then a military technician, served just at the gas station of these same airbuses. So. There was no gasoline, that is, completely. He tried using electric winches to lower flying bodies. However, the electricity soon ran out. Many different sources of alternative energy have been tried.

One day, a military technician thought that hydrogen could be used in other ways than just bleed into the sky. After all, the heat that this gas gives out during combustion is 4 times higher than that from coal, 3 times higher than that from gasoline and other petroleum products. Shelitz asked permission for the experiment, and it was signed for him. Do I need to say that this is how a hydrogen car appeared?

Principle of operation

The scientist's scheme boiled down to connecting the airbus with a hose to the inlet manifold of a car engine. Hydrogen entered directly into the cylinders, bypassing the carburetor. The dosage of hydrogen, as well as the air necessary for the reaction, was carried out using a throttle valve or the “gas” pedal.

Shelitz carried out his first experiments in frost. The engine started easily, despite the temperature outside. The motor worked stably and for a long time. True, the balloons exploded, and Shelitz was shell-shocked. After that, a special protection system was invented. It is based on a water seal, which excluded the ignition of the mixture during flashes in the motor manifold. So the car on hydrogen has become safer.

By the way, after one of the engines was dismantled, there were practically no signs of wear on it. There was no carbon deposits in the cylinders, and the exhaust gases were only water vapor.

Hydrogen saves lives

The hydrogen machine invented in this way during the war helped save many lives, withstand the blockade, and Shelitz himself received an award for this development, and even patented it. The developer was awarded the Red Star.

Hydrogen Taxi

After the war, when there was nowhere to get hydrogen, they began to forget about it. However, some people still remember how in Ukraine, in Kharkov, a taxi worked, but not a simple one, but a hydrogen one.

Save with Brown's Gas

In most of even the most modern automotive internal combustion engines, fuel burns far from optimally. About 60% of the mixture of air and fuel is simply lost in the bowels of the exhaust manifold. In the collector, the mixture does not burn out completely, and at the same time it also forms quite toxic exhaust gases.

You can use a hydrogen generator. This is a fundamentally new equipment that will significantly save on fuel in the car. Most of these devices have a standard circuit diagram. However, the hydrogen generator itself for cars from different manufacturers may have certain differences.

Hydrogen has been used as a fuel additive for a long time. But then there were no systems to optimize the mixture of fuel and the so-called Brown's gas, which was fed into the cylinders.

A hydrogen generator for a car uses the principle of electrolysis in its work. Water is used here as a catalyst. But it does not decompose into two components - oxygen and hydrogen. Modern generators use nothing more than Brown's gas. It is a brown or green hydrogen. It is sometimes referred to as water gas or oxyhydrogen. Its formula is HHO. Its difference is that it is completely safe and does not explode. In addition, all the gas that is produced will completely enter the cylinders.

Such generators consist of a device that produces electrolysis and a container. Electrolysis processes are controlled by a special modulator. In injection engines, the design also provides for an optimizer. It allows you to automatically adjust the ratio of mixing fuel and air with Brown's gas.

Types of catalysts

The devices that are used in electrolyzers are simple, split-cell and dry type.

In the first case, the electrolyzer has the simplest and rather primitive design. Its management is also very simple. Method device

website

Hydrogen engine for a car, how to get rid of oil addiction

If you find an error in the text, select it with the mouse and press Ctrl+Enter. Thank you.

Oil reserves are coming to an end, which forces humanity to look for alternative energy sources that can replace "black gold". One solution is to use a hydrogen engine, which is less toxic and more efficient. The main thing is that the supply of raw materials for the production of fuel is almost unlimited.

When did the hydrogen engine for the car appear? What are the features of its device, and what is the principle of operation? Where is this technology applied? Is it possible to make such a motor with your own hands? These and other questions will be discussed below.

When the hydrogen engine appeared, the main companies leading its development

Interest in the use of hydrogen appeared back in the 1970s during a period of acute fuel shortage. Toyota was the first modern developer to introduce a hydrogen-powered car engine. It was he who in 1997 put on public display the FCHV SUV, which never went into mass production.

Despite the initial setback, many companies continue to research and even manufacture such vehicles. Toyota, Hyundai and Honda have achieved the greatest success. Other companies are also developing - Volkswagen, General Motors, BMW, Nissan, Ford.

In 2016, the first hydrogen-powered train appeared, which is the brainchild of the German company Alstom. The new Coranda iLint is scheduled to start operating at the end of 2017 on the route from Buxtehude to Cuxhaven (Lower Saxony).

In the future, it is planned to replace 4,000 German diesel trains with such trains, moving along sections of roads without electrification.

Norway, Denmark and other countries have already shown interest in buying Coranda iLint.

Features of hydrogen as an engine fuel

In the internal combustion engine, gasoline is mixed with air, after which it is fed into the cylinders and burns, as a result of which the pistons move and the vehicle moves.

The use of hydrogen as a fuel has a number of nuances:

- After combustion of the fuel mixture, only steam is produced at the outlet.

- The ignition reaction is faster than with diesel or gasoline.

- Due to knock resistance, it is possible to increase the compression ratio.

- The heat transfer of hydrogen is 250% higher than that of the fuel-air mixture.

- Hydrogen is a volatile gas, so it gets into the smallest gaps and cavities. For this reason, few metals are able to withstand its destructive influence.

- Such fuels are stored in liquid or compressed form. In the event of a breakdown of the tank, hydrogen evaporates.

- The lower level of the proportion of gas to react with oxygen is 4%. Thanks to this feature, it is possible to adjust the operating modes of the motor by dosing the consistency.

Taking into account the listed nuances, it is impossible to use h3 in its pure form for an internal combustion engine. It is required to make structural changes to the internal combustion engine and install additional equipment.

Hydrogen engine device

Cars with a hydrogen-powered engine are divided into several groups:

- Machines with 2 energy carriers. They have an economical engine that can run on pure hydrogen or a gasoline mixture. The efficiency of this type of engine reaches 90-95 percent. For comparison, a diesel engine has an efficiency of 50%, and a conventional internal combustion engine - 35%. Such vehicles comply with the Euro-4 standard.

- A car with a built-in electric motor that powers the hydrogen cell on board the vehicle. Today it was possible to create motors with an efficiency of 75% or more.

- Conventional vehicles running on pure hydrogen or air/fuel mixture. The peculiarity of such engines is clean exhaust and an increase in efficiency by another 20%.

As noted above, the design of a motor running on h3 is almost the same as an internal combustion engine, with the exception of some aspects.

The main feature is the method of supplying fuel to the combustion chamber and igniting it. As for the conversion of the received energy into the movement of the KShM, the process is similar.

Principle of operation

The principle of operation of hydrogen engines should be considered in relation to two types of such installations:

- Internal combustion engines;

- Engines on hydrogen elements.

Hydrogen internal combustion engines

In an internal combustion engine, due to the fact that the combustion of the gasoline mixture is slower, the fuel enters the combustion chamber before the piston reaches its top point.

In a hydrogen engine, due to the instantaneous ignition of the gas, it is possible to shift the injection time until the piston begins to return. At the same time, for normal operation of the engine, a small pressure in the fuel system (up to 4 atmospheres) is sufficient.

Under optimal conditions, the hydrogen motor is capable of operating with a closed feed system. This means that during the formation of the mixture, atmospheric air is not used.

After the compression stroke is completed, steam remains in the cylinder, which is sent to the radiator, condenses and becomes water.

The implementation of the option is possible if the machine is equipped with an electrolyser - a device that provides the separation of hydrogen from h3O for subsequent reaction with O2.

It has not yet been possible to translate the described system into reality, because oil is used for the normal operation of the engine and to reduce friction.

The latter evaporates and is part of the exhaust gases. So the use of atmospheric air during the operation of a hydrogen engine is still necessary.

Hydrogen powered engines

The principle of operation of such devices is based on the flow of chemical reactions. The cell casing has a membrane (conducts only protons) and an electrode chamber (it contains a cathode and an anode).

h3 is supplied to the anode section, and O2 is supplied to the cathode chamber. A special coating is applied to the electrodes, which acts as a catalyst (usually platinum).

Under the action of the catalytic substance, hydrogen loses electrons. Further, protons are brought through the membrane to the cathode, and water is formed under the influence of the catalyst.

From the anode chamber, the electrons exit into an electrical circuit connected to the motor. This generates current to power the motor.

Where have hydrogen fuel cells been used?

A feature of hydrogen-type fuel cells is the ability to produce energy for an electric motor. As a result, the system replaces the internal combustion engine or becomes an on-board power source on the vehicle.

Fuel cells were first used in 1959 by a US company.

Generally speaking, fuel cells are used:

Hydrogen fuel cells have also found application in forklifts, bicycles, scooters, motorcycles, tractors, golf cars and other vehicles.

Advantages and disadvantages

To understand the features and prospects of a hydrogen engine in a car, it is worth knowing its pros and cons. Let's consider them in more detail.

- ENVIRONMENTAL FRIENDLY. The introduction of a hydrogen engine is an opportunity to forget about the problem of environmental pollution. With a global transition to this type of fuel, it will be possible to reduce the greenhouse effect and, possibly, save the planet. The environmental friendliness of new developments is confirmed by Toyota. The employees of the concern proved that the exhaust from the car is safe for health. Moreover, the water coming out can be drunk, because it is distilled and purified from impurities.

- DEVELOPMENT EXPERIENCE. It is known that the hydrogen engine was created a long time ago, so there should be no problems with its use in cars. If you delve into history, the first semblance of a hydrogen engine at the beginning of the 19th century was created by Francois Isaac de Rivaz, a designer from France. In addition, during the blockade of Leningrad, almost 500 vehicles were transferred to a new type of fuel.

- AVAILABILITY. An equally important factor in favor of h3 is the absence of a deficiency. If desired, this type of fuel can even be obtained from wastewater.

- POSSIBILITY OF APPLICATION IN DIFFERENT POWER INSTALLATIONS. There is an opinion that hydrogen is used only in internal combustion engines. This is not true. The new technology is involved in the creation of a fuel cell, with the help of which it is possible to obtain electric current and power the electric motor of the vehicle. The advantages are safety and the absence of fossil elements, which eliminates environmental pollution. At the present stage, such a scheme is considered the safest and is most in demand among developers.

Also, the pluses include:

- Minimum noise level;

- Improving power, throttle response and other engine parameters;

- Large power reserve;

- Low fuel consumption;

- Ease of maintenance;

- High potential for use as an alternative fuel.

Disadvantages of a hydrogen engine:

In addition to those already discussed above, it is worth highlighting a number of disadvantages:

- Fire or explosion hazard.

- Risks for the planet, because an increase in the volume of hydrogen can lead to irreparable consequences for the ozone layer.

- An increase in the weight of the machine due to the use of powerful batteries and converters.

- The presence of problems with the storage of hydrogen fuel - under high pressure or in liquefied form. Researchers have yet to come to a unanimous conclusion as to which option is better.

The danger of hydrogen fuel

In the disadvantages discussed above, the dangers of using hydrogen fuel for the engine were mentioned. This is the main disadvantage of the new technology.

In combination with an oxidizing agent (oxygen), the risk of hydrogen ignition or even explosion increases. Studies have shown that 1/10 of the energy needed to ignite the gasoline mixture is enough to ignite h3. In other words, a static spark is enough to ignite hydrogen.

Another danger lies in the invisibility of the hydrogen flame. When a substance is burning, the fire is almost invisible, which complicates the process of fighting it. In addition, an excessive amount of h3 leads to suffocation.

The danger is that it is extremely difficult to recognize this gas, because it has no smell and is completely invisible to the human eye.

In addition, liquefied h3 has a low temperature, so in the event of a leak with exposed body parts, there is a high risk of severe frostbite. This gas is located in special storage facilities.

From the above, the conclusion suggests itself that the hydrogen engine is dangerous, and it is extremely risky to use it.

In fact, hydrogen gas is light in weight and will dissipate into the air if leaked. This means that the risk of its ignition is minimal.

In the case of suffocation, this situation is possible, but only when in a closed room. Otherwise, the leakage of hydrogen fuel does not pose a danger to life. In justification, it is worth noting that the exhaust gases of internal combustion engines (namely carbon monoxide) also carry a deadly risk.

Modern cars with hydrogen engines

The possibility of using hydrogen fuel engines has interested many manufacturers. As a result, more and more cars running on this gas appear in the automotive industry.

The most popular models include:

- Toyota has released the Fuel Cell Sedan. To eliminate problems with the lack of space in the cabin and luggage compartment, hydrogen fuel tanks are placed on the floor of the vehicle. Fuel Cell Sedan is designed to transport people, and its cost is 67.5 thousand dollars.

- The BMW concern presented its version of the Hydrogen car. The new model has been tested by well-known cultural figures, businessmen, politicians and other popular personalities. Tests have shown that switching to a new fuel does not affect the comfort, safety and dynamics of the vehicle. If necessary, types of fuel can be switched from one to another. Hydrogen7 speed - up to 229 km / h.

- Honda Clarity is a car from the Honda concern that impresses with its power reserve. It is 589 km, which no other low-emission vehicle can boast of. Refueling takes three to five minutes.

- "Monster" from General Motors shown in October 2016. The peculiarity of the car lies in the incredible reliability, which is confirmed by the research carried out by the US Army. During the tests, the vehicle covered more than 3 million kilometers.

- Toyota has launched a hydrogen model Mirai on the market. Sales began back in 2014 in Japan, and in the US since October 2015. Mirai refueling time is five minutes, and the cruising range on one gas station is 502 km. PHOTO 21 22 Recently, representatives of the concern announced that they plan to implement this technology not only in cars, but also in forklifts and even trucks. The 18 wheeler truck is already being tested in Los Angeles.

- Manufacturer Lexus is planning a hydrogen-powered variant of the car in 2020, so few details are known about the vehicle.

- Audi unveiled the H-tron Quattro concept in Detroit. According to the manufacturer, the car can travel about 600 km on one tank, and it is possible to pick up speed up to 100 km/h in 7.1 seconds. The machine has a "virtual" cockpit that replaces the standard dashboard.

- BMW is working with Toyota to launch its hydrogen vehicle by 2020. The manufacturer assures that the power reserve of the new model is more than 480 km, and refueling will take up to 5 minutes.

- In 2013, Ford announced that active production of hydrogen engines would begin by the end of 2017 in cooperation with Nissan and Mercedes-Benz. But it has not yet been possible to implement the plan in practice - the concern's employees are at the development stage.

- Mercedes-Benz has unveiled the GLC SUV at the Frankfurt Motor Show, which will hit the market at the end of 2019. The car is equipped with a 9.3 kWh battery, and the power reserve is 436 km. Top speed is electronically limited to 159 km/h.

- Nikola Motor presented a hydrogen-powered truck with a range of 1287 to 1931 km. The cost of a new car will be 5-7 thousand dollars for rent per month. The release is planned to start in 2020.

- Manufacturer Hyundai has created a new line of Tucson. To date, 140 machines have been produced and sold. Hyundai Genesis brand unveiled its GV hydrogen-powered vehicle The vehicle was first unveiled in New York, but production is not yet planned.

- The UK is also not far behind in terms of new technologies. It is already possible to rent a Riversimple Rasa hydrogen car in the country for three or six months. The car weighs a little more than 500 kg and is able to drive about 500 km on one gas station.

- Design house Pininfarina has created the h3 Speed, a hydrogen-powered car. The peculiarity of the car lies in the ability to accelerate to hundreds in just 3.4 seconds, and the maximum speed is 300 km / h. Refueling time is only three minutes. The cost of the new model reaches 2.5 million dollars.

Difficulties in the operation of hydrogen internal combustion engines

The main obstacle to the introduction of new technology is the excessive cost of obtaining hydrogen fuel, as well as the purchase of component materials.

There are also problems with storing h3. So, to keep the gas in the required state, a temperature of -253 degrees Celsius is required.

The simplest way to produce hydrogen is by electrolysis of water. If the production of h3 is required on an industrial scale, high energy costs cannot be dispensed with.

To increase the profitability of production, it is necessary to use the possibilities of nuclear energy. To avoid risks, scientists are trying to find alternatives to this option.

Moving and storage requires the use of expensive materials and high quality mechanisms.

We must not forget about other difficulties that one has to face during operation:

- Explosiveness. If the gas leaks in a closed room and there is little energy for the reaction to proceed, an explosion is possible. If the air is too hot, it only aggravates the situation. The high permeability h3 causes the gas to enter the exhaust manifold. That is why the use of a rotary motor is considered more preferable.

- When storing hydrogen, containers with a large volume are used, as well as systems that exclude gas volatilization. In addition, devices are used that exclude mechanical damage to the containers. If this feature is not of great importance for trucks, water or passenger transport, a passenger car loses valuable cubic meters.

- At high loads and high temperatures, h3 provokes the destruction of the elements of the CPG (cylinder-piston group) and the lubricant in the engine. The use of special alloys and lubricants increases the production cost of hydrogen engines.

The future of hydrogen engines

The application of h3 opens up great prospects and not only in the automotive sector. Hydrogen engines are actively used in railway transport, airplanes and helicopters. They are also installed on auxiliary equipment.

Interest in the development of such motors is shown by many concerns, which have already been mentioned above - Toyota, BMW, Volkswagen, General Motors and others.

Already today on the roads there are real cars that run on hydrogen. Many of them are discussed above - BMW 750i Hydrogen, Honda FSX, Toyota Mirai and others.

Almost all large concerns, which are trying to find their niche in the market, have joined the work.

The main disadvantage is the high price of h3, the lack of gas stations, as well as the shortage of qualified workers capable of servicing such equipment. If the existing problems can be solved, cars with hydrogen engines will definitely appear on our roads.

Competing Technologies

Attention to motors on hydrogen is dispelled for the reason that the technology has competitors.

Here are just a few of them:

Is it possible to do it yourself?

The technology of engine operation on gas has been known for a long time, and many concerns have achieved success in introducing hydrogen engines. Craftsmen also thought about improving the classic ICE.

The bottom line is to supply a special gas to the combustion chamber. Such a device is called the Brown system. In this case, gasoline is also supplied to the engine, but mixed with gas, which ensures better combustion.

As a result, water vapor appears, which cleans the valves and pistons of the engine from carbon deposits, improves engine performance and increases its life.

To decompose water into gas with your own hands, you need a catalyst, distillate, electrodes and electricity.

The design is assembled from improvised materials. It is allowed to use one can, but it is better to use six.

After that, the plates are cut out and combined according to the principle of crosswise. Then they are wrapped with wire and attached to the lid. It is important that the electrodes do not short circuit with each other.

At the last stage, the jars are filled with electrolyte and catalyst. Such a scheme can work on any car.

If we talk about a full-fledged hydrogen engine, then of course it will not be possible to make it in garage conditions due to the complexity of the technology.

If the article has a video and it does not play, select any word with the mouse, press Ctrl + Enter, enter any word in the window that appears and click "Submit". Thank you.

THIS MAY BE USEFUL:

autotopik.ru

DIY hydrogen generator

DIY hydrogen generator

.........................................................................................................

Do you want to make a hydrogen generator for a car? Thousands of people who are developing their own hydrogen generators are installing them in vehicles to run on water due to ever-increasing fuel prices. If you're one of the many people who are looking to save money or are trying to find ways to cut costs, you've probably heard the talk about hydrogen for cars and how to build your own generator.

I first heard about hydrogen for cars a few months ago, and although I was very skeptical, I still decided to find out about it and did some research. It turned out that Brown's gas is not only easy to obtain by electrolysis, but also the simplest plants have been sold in the USA for a long time helping to save from 30% to 50% of fuel

Design:

So how does a hydrogen generator work?

These hydrogen fuel cells for cars consist of a small container or vessel of water placed under the hood, pour plain tap water into the vessel, drop in a teaspoon of catalyst, baking soda and dip some stainless steel plates. We connect these plates to the battery and when the ignition is turned on, gas begins to be produced. We mount the hydrogen hose in the air duct after the filter.

Once this is all properly installed, it is possible to extract hydrogen and oxygen (HHO) from water using electrolysis (a process where electricity is used to break water molecules into HHO). This mixture of hydrogen and oxygen is then drawn into your car's intake manifold, where it mixes with regular gasoline from the fuel tank and burns in the engine in the normal way.

This mixture of gasoline and HHO burns more efficiently, which greatly improves engine performance and saves fuel. In some cases up to 50%. It also increases the power of your engine.

It turns out that making your own hydrogen generator in a car is not only quite simple, but also cheap. It cost us less than $100.

There are tons of tutorials on the internet, if you want to see the details post a hydrogen generator on YouTube.

The reserves of hydrogen bound in water are practically inexhaustible. Breaking the atomic bonds allows hydrogen to be produced and then used as fuel. Numerous processes have been developed to decompose water into its constituent elements.

Hydrogen generators

............................................................................................................................................................................................

From TV screens we are told that the amount of oil is rapidly decreasing, and soon gasoline cars will become a thing of the distant past. That's just not entirely true.

Indeed, the number of proven oil reserves is not very large. Depending on the degree of consumption, they can last for a period of 50 to 200 years. But these statistics do not take into account hitherto unexplored oil production sites.

In fact, there is more than enough oil on our planet. Another question is that the complexity of its extraction is constantly increasing, which means that the price is also growing. In addition, the environmental factor cannot be discounted. Exhaust gases pollute the environment a lot and something needs to be done about it.

Modern science has created many alternative energy sources up to the engine of nuclear fission in your machines. But most of these technologies are still concepts without the possibility of real application. At least that was the case until recently.

Every year, machine-building companies produce more and more machines that run on alternative power sources. One of the most effective solutions in this context is a hydrogen engine from the Toyota brand. It allows you to completely forget about gasoline, making the car an environmentally friendly and cheap vehicle.

Hydrogen engines

Types of hydrogen engines and their description

Science is constantly evolving. New concepts come up every day. But only the best of them come true. Now there are only two types of hydrogen engines that can be cost-effective and productive.

The first type of hydrogen engine runs on fuel cells. Unfortunately, hydrogen engines of this type still have a high cost. The fact is that the design contains expensive materials like platinum.

The second type includes hydrogen internal combustion engines. The principle of operation of such devices is very similar to propane models. That is why they are often reconfigured to work under hydrogen. Unfortunately, the efficiency of such devices is an order of magnitude lower than those that operate on fuel cells.

At the moment, it is hard to say which of the two technologies for creating hydrogen engines will win. Each has its pros and cons. In any case, work in this direction does not stop. Therefore, it is quite possible that by 2030 a car with a hydrogen engine can be bought at any car dealership.

Principle of operation

The hydrogen engine works on the principle of electrolysis. This process takes place in water under the influence of a special catalyst. As a result, hydrogen is released. Its chemical formula is as follows - HHO. The gas is not explosive.

Important! Inside special containers, the gas is mixed with the fuel-air mixture.

The generator includes an electrolyzer and a tank. The current modulator is responsible for the gas generation process. To ensure the best results, an optimizer is installed in injection hydrogen engines. This device is responsible for regulating the ratio of the fuel-air mixture and Brown's gas.

Characteristics of catalysts

The catalysts used to create the desired reaction in a hydrogen engine can be of three types:

- Cylindrical banks. This is the simplest design, operating on a rather primitive control system. The performance of a hydrogen engine operating with this catalyst does not exceed 0.7 liters of gas per minute. Such systems can be used on cars with a hydrogen engine up to one and a half liters. Increasing the number of cans allows you to exceed this limit.

- Separate cells. It is believed that this type of catalyst is the most efficient. The performance of the system is more than two liters of gas per minute, the efficiency is maximum.

- Open plates or dry catalyst. This system is designed to last a long time. Productivity fluctuates in the range from one to two liters of gas a minute. The open position provides the most efficient cooling.

The efficiency of hydrogen engines is growing every year. Hybrid devices operating on hydrogen and gasoline are now beginning to be put into operation. In turn, designers do not stop looking for the most efficient catalyst model that provides even greater performance.

DIY hydrogen engine

Generator

To create an efficient hydrogen engine for a car with your own hands, you need to start with a generator. The simplest homemade generator is a sealed container with liquid into which the electrodes are immersed. For such a device, a 12 V power supply is sufficient.

The fitting is installed on the cover of the structure. It removes a mixture of hydrogen and oxygen. Actually, this is the basis of the generator for the hydrogen engine, which is connected to the internal combustion engine.

To create a complete system, you will also need an additional drive and battery. It is best to use a water filter as a housing, or you can buy a special installation. In the latter, cylindrical electrodes of increased productivity are used.

As you can see, isolating the right gas for the reaction is not so difficult. It is much more difficult to produce it in the amount needed for a hydrogen engine. To increase the efficiency it is necessary to use copper electrodes. In extreme cases, stainless steel is also suitable.

During the reaction, the current must be supplied with different strengths. Therefore, without an electronic unit can not do. In addition, there must always be a certain amount of water in the tank so that the reaction takes place under normal conditions. The automatic feeding system in the hydrogen engine solves this problem. The intensity of the electrolysis provides a sufficient amount of salt.

Important! If the water is distilled, there will be no electrolysis at all.

To make water for a hydrogen engine, you need to take 10 liters of liquid and add a tablespoon of hydroxide.

Hydrogen engine device

First of all, you need to take care of additional tanks and pipelines. The hydrogen engine needs a water level sensor, which is installed in the middle of the cover. This will prevent false triggering when moving up and down. It is he who will give the command to the automatic recharge system when needed.

The pressure sensor plays a special role. It turns on at 40 psi. As soon as the internal pressure reaches 45 psi, the pumping is turned off. Above 50 psi the fuse will trip.

The fuse for a hydrogen engine must consist of two parts: an emergency release valve and a rupture disc. The rupture disk will activate when the pressure reaches 60 psi without causing any harm to the system.

To remove heat, you need to use the coldest candle. Candles with platinum tips are not suitable. Platinum is an excellent catalyst for the reaction of hydrogen and oxygen.

Important! Pay special attention to creating crankcase ventilation for the hydrogen engine.

Electrical part

An important role in the electrical circuit of the hydrogen engine is played by the 555 timer. It acts as a pulse generator. Moreover, it can be used to adjust the frequency and pulse width.

Important! The timer has three frequency ranges. The resistance of the resistors is within 100 ohms. The connection takes place in parallel.

The hydrogen engine board should have two 555 pulse timers. The first one should have larger capacitors. The output from leg 3 goes to the second generator. He actually turns it on.

The third output of the second timer of the pulsed hydrogen generator is connected to 220 and 820 ohm resistors. The transistor amplifies the current to the desired value. The diode 1N4007 is responsible for its protection. This ensures the normal operation of the entire system.

Results

Now the hydrogen engine is no longer a figment of the imagination of scientists, but a very real development that you can do yourself. Of course, in terms of characteristics, such a unit will be inferior to the factory model. But the savings for the internal combustion engine will still be noticeable.

Hydrogen engines not only help reduce gasoline consumption, but are also completely environmentally friendly. That is why, in the first quarter, sales of Toyota's hydrogen car broke all records in Japan.

The use of hydrogen as an energy source for heating a house is a very tempting idea, because its calorific value (33.2 kW / m3) is more than 3 times higher than that of natural gas (9.3 kW / m3). Theoretically, in order to extract combustible gas from water and then burn it in a boiler, a hydrogen generator can be used for heating. What can come of this and how to make such a device with your own hands will be described in this article.

The principle of operation of the generator

As an energy carrier, hydrogen really has no equal, and its reserves are practically inexhaustible. As we have already said, when burned, it releases a huge amount of thermal energy, incomparably more than any hydrocarbon fuel. Instead of harmful compounds emitted into the atmosphere when using natural gas, the combustion of hydrogen produces ordinary water in the form of steam. One problem: this chemical element does not occur in nature in a free form, only in combination with other substances.

One of these compounds is ordinary water, which is completely oxidized hydrogen. Many scientists have been working on its splitting into its constituent elements for many years. It cannot be said that it was ineffective, because a technical solution for the separation of water was nevertheless found. Its essence lies in the chemical reaction of electrolysis, as a result of which water is split into oxygen and hydrogen, the resulting mixture was called explosive gas or Brown's gas. Below is a diagram of a hydrogen generator (electrolyzer) powered by electricity:

Electrolyzers are mass-produced and designed for gas-flame (welding) work. A current of a certain strength and frequency is applied to groups of metal plates immersed in water. As a result of the ongoing electrolysis reaction, oxygen and hydrogen are released mixed with water vapor. To separate it, the gases are passed through the separator, after which they are fed to the burner. In order to avoid a kickback and explosion, a valve is installed at the supply that allows fuel to pass only in one direction.

To control the water level and timely make-up, the design provides a special sensor, on the signal of which water is injected into the working space of the electrolyzer. Overpressure inside the vessel is monitored by an emergency switch and a relief valve. The maintenance of the hydrogen generator is to periodically add water, and that's it.

Hydrogen heating: myth or reality?

The welding generator is currently the only practical application for electrolytic water splitting. It is not advisable to use it for heating a house, and here's why. Energy costs during gas-flame work are not so important, the main thing is that the welder does not need to carry heavy cylinders and fiddle with hoses. Another thing is home heating, where every penny counts. And here hydrogen loses to all currently existing types of fuel.

Important. The cost of electricity for the separation of fuel from water by electrolysis will be much higher than the explosive gas can be released during combustion.

Mass-produced welding generators cost a lot of money because they use catalysts for the electrolysis process, which include platinum. You can make a hydrogen generator with your own hands, but its efficiency will be even lower than that of a factory one. You will definitely succeed in getting combustible gas, but it is unlikely that it will be enough to heat at least one large room, let alone a whole house. And if enough, you will have to pay fabulous electricity bills.

Rather than spending time and effort on getting free fuel, which does not exist a priori, it is easier to make a simple electrode boiler with your own hands. You can be sure that in this way you will use much less energy with greater benefit. However, home craftsmen - enthusiasts can always try their hand and assemble an electrolyzer at home in order to conduct experiments and see for themselves everything. One of these experiments is shown in the video:

How to make a generator

A lot of Internet resources publish a variety of schemes and drawings of a generator for producing hydrogen, but they all operate on the same principle. We will bring to your attention a drawing of a simple device, taken from popular science literature:

Here, the electrolyzer is a group of metal plates bolted together. Insulating spacers are installed between them, the extreme thick plates are also made of a dielectric. From the fitting, mounted in one of the plates, there is a tube for supplying gas to a vessel with water, and from it to the second. The task of the tanks is to separate the steam component and accumulate a mixture of hydrogen and oxygen in order to supply it under pressure.

Advice. Electrolytic plates for the generator must be made of stainless steel alloyed with titanium. It will serve as an additional catalyst for the splitting reaction.

The plates that serve as electrodes can be of any size. But we must understand that the performance of the apparatus depends on their surface area. The more electrodes you can use in the process, the better. But at the same time, the current consumption will be higher, this should be taken into account. Wires leading to a source of electricity are soldered to the ends of the plates. Here, too, there is a field for experiments: you can apply different voltages to the electrolyzer using an adjustable power supply.

As an electrolyzer, you can use a plastic container from a water filter by placing electrodes from stainless tubes in it. The product is convenient in that it is easy to seal it from the environment, leading the tube and wires through the holes in the cover. Another thing is that this homemade hydrogen generator has a low performance due to the small area of the electrodes.

Conclusion

At the moment, there is no reliable and efficient technology that allows the implementation of hydrogen heating of a private house. Those generators that are commercially available can be successfully used for metal processing, but not for the production of fuel for the boiler. Attempts to organize such heating will lead to an overrun of electricity, not counting the cost of equipment.

Modern methods of heating buildings and premises are offered on the domestic market in the form of many options. It is understandable that consumers choose those that promise maximum efficiency at minimum cost.

One of the alternative ways to heat a room is the use of a hydrogen generator.

A bit of history

The principle of operation of hydrogen energy was noted in ancient times. The famous healer Paracelsus, during his scientific experiments, noticed that when some elements are combined, bubbles form, which at that time he mistook for air. Later it turned out that it was hydrogen, which is a gas without color, under certain conditions, exhibiting explosive properties.

At present, hydrogen has been learned to be used for various purposes, including for heating a residential building or any other structures. These technologies are being actively developed and implemented in many industries. Being an innovation in the market of scientific developments, heating with hydrogen has already attracted the interest of many consumers and continues to gain popularity among the general public.

It has been proven that hydrogen is considered not only a fairly common, but also an easily accessible substance. The only difficulty is that it has to be extracted from chemical compounds, most often water.

Features of the hydrogen generator

Based on the requirements and quadrature of a private or municipal building, it is necessary to choose a hydrogen burner with an optimal power level adapted to the needs of a particular room. It should be noted that the maximum possible generator power is 6.

The production of hydrogen, rightfully recognized as the most economical type of fuel, is possible in any quantity. A prerequisite for this is the availability of electricity, as well as water.

The main task of the equipment is a full-fledged independent heating of premises. However, hydrogen-based installations can perfectly complement existing home heating systems. It is only necessary to ensure that all elements of the heating system function at low temperatures.

Also, these units are used to heat the room with underfloor heating, which are currently easy to assemble with your own hands.

The principle of operation of the device

The heat generation process is based on the electrolysis of water in an environment saturated with a catalyst. The main condition for normal operation, as well as the safety of the generator, is that under such conditions, water does not decompose into oxygen and hydrogen, the combination of which can be explosive.

Modern generators operate to produce Brown's gas. This is a completely non-explosive substance of a brownish or green hue, also called water gas. After working out and heating up to 40 degrees, it immediately goes to the combustion chambers, and more specifically, to the heat exchanger. There it is mixed with air-fuel cells.

The main structural components of the simplest hydrogen unit are pipes and the boiler itself. Often no technical accessories or additional elements and fixtures are needed anymore.

This also applies to components designed to remove combustion products. Indeed, as a result of the functioning of the generator, only steam is released into the atmosphere: water, clean and completely safe.

Often these types of burners are modular in design, each part of which has its own catalyst, which increases the overall efficiency of the system.

As for pipes for the system, it is advisable to use those whose diameter is in the range from 1 to 1.25 inches. Some deviations are allowed, but most often these are used to heat the house. An important rule that should not be neglected when installing heating pipes is that each previous branch must be larger in diameter than the next.

Features of Electrolytic Hydrogen Generator

A hydrogen generator based on the principle of electrolysis is most often produced in a container version. A prerequisite for the acquisition of such a device for heating is the presence of the following documents: permission from Rostekhnadzor, certificates (compliance with GOSTR and hygienic).

The electrolytic generator consists of the following elements:

- a block that includes a transformer, a rectifier, junction boxes and devices, a block for replenishing and demineralizing water;

- devices for separate production of hydrogen and oxygen - an electrolyzer;

- gas analysis systems;

- liquid cooling systems;

- a system aimed at detecting a possible hydrogen leak;

- control panels and automatic control systems.

To achieve the most efficient process of electrical conductivity, lye drops are used. The tank with it is replenished as needed, but most often this happens about 1 time per year.

Any electrolytic generators of industrial type are produced on the basis of European environmental and safety standards.

It has been experimentally proven that the purchase of a hydrogen electrolytic generator is much more profitable than the regular purchase of gas. So, for the production of 1 cubic meter of gas from hydrogen and oxygen, only about 3.5 kW of electrical energy is required, as well as half a liter of demineralized water.

Benefits of using a hydrogen unit

The device attracts many for the following reasons:

- The efficiency is about 90%, the technique competes with the most advanced achievements of science and technology related to heating any home.

- There is no need to use a flame to achieve heat. The whole process is based on chemical reactions with catalysts.

- Absolute harmlessness of the device.

- Hydrogen generators are sources of clean energy that cannot be exhausted.

- The use of hydrogen as the main source of heat minimizes the need for the constant exploitation of fossil resources, the extraction costs of which are many times higher than the costs of producing heat from hydrogen.

- Perfect soundlessness of the unit. Installation of the device does not require separate chimneys.

Negative aspects of hydrogen-type building heating

In fairness, it is worth highlighting some of the disadvantages of this heating method:

- explosion hazard, which can be provoked by incorrect operation of the unit;

- insufficient prevalence of hydrogen devices in the Russian market, which is accompanied by problems with the installation or purchase of equipment;

- lack of specialists and service masters capable of certifying or servicing heating appliances of this class.

Is it possible to independently create a hydrogen generator?

It is better not to take risks, because such a process is associated not only with the need to know the intricacies of technology and chemistry, but also requires proper compliance with safety rules. But do-it-yourself installation of equipment is possible. To do this, it is enough to follow the instructions and not allow amateur performance.

The heating of any house should provide not only comfortable living for a person, but also the ecological cleanliness of the environment. This is achieved due to the fact that after the combustion of hydrogen, no harmful compounds are formed.

In Western countries, heating with hydrogen generators has gained wide acceptance and economic justification. If a similar method takes root in Russia, it will significantly increase the heating efficiency with minimal resource costs.

The rise in energy prices stimulates the search for more efficient and cheaper types of fuel, including at the household level. Most of all craftsmen - enthusiasts are attracted by hydrogen, whose calorific value is three times higher than methane (38.8 kW versus 13.8 per 1 kg of substance). The method of extraction at home, it would seem, is known - the splitting of water by electrolysis. In reality, the problem is much more complex. Our article has 2 goals:

- to analyze the question of how to make a hydrogen generator at minimal cost;

- consider the possibility of using the installation for heating a private house, refueling a car and as a welding machine.

Brief theoretical part

Hydrogen, also known as hydrogen, - the first element of the periodic table - is the lightest gaseous substance with high chemical activity. During oxidation (that is, combustion), it releases a huge amount of heat, forming ordinary water. We characterize the properties of the element, arranging them in the form of theses:

For reference. The scientists who first separated the water molecule into hydrogen and oxygen called the mixture explosive gas because of its propensity to explode. Subsequently, it was called Brown's gas (after the name of the inventor) and began to be denoted by the hypothetical formula HNO.

Previously, airships were filled with hydrogen, which often exploded.

Previously, airships were filled with hydrogen, which often exploded. From the foregoing, the following conclusion suggests itself: 2 hydrogen atoms easily combine with 1 oxygen atom, but they part very reluctantly. The chemical oxidation reaction proceeds with the direct release of thermal energy in accordance with the formula:

2h3 + O2 → 2h3O + Q (energy)

Here lies an important point that will be useful to us in further debriefing: hydrogen reacts spontaneously from ignition, and heat is released directly. To separate a water molecule, energy will have to be expended:

2h3O → 2h3 + O2 - Q

This is a formula for an electrolytic reaction that characterizes the process of splitting water by supplying electricity. How to implement this in practice and make a hydrogen generator with your own hands, we will consider further.

Creation of a prototype

In order for you to understand what you are dealing with, to begin with, we propose to assemble the simplest generator for the production of hydrogen at minimal cost. The design of a home-made installation is shown in the diagram.

What does a primitive electrolyzer consist of:

- reactor - a glass or plastic container with thick walls;

- metal electrodes immersed in a reactor with water and connected to a power source;

- the second tank plays the role of a water seal;

- tubes for HHO gas outlet.

An important point. The electrolytic hydrogen plant operates only on direct current. Therefore, use a wall adapter, car charger or battery as a power source. The alternator will not work.

The principle of operation of the electrolyzer is as follows:

To make the generator design shown in the diagram with your own hands, you will need 2 glass bottles with wide necks and lids, a medical dropper and 2 dozen self-tapping screws. A complete set of materials is shown in the photo.

Of the special tools, you will need a glue gun to seal the plastic caps. The manufacturing process is simple:

To start the hydrogen generator, pour salted water into the reactor and turn on the power source. The beginning of the reaction will be marked by the appearance of gas bubbles in both containers. Adjust the voltage to the optimum value and ignite Brown's gas coming out of the dropper needle.

Second important point. Too high voltage must not be applied - the electrolyte, heated to 65 ° C or more, will begin to evaporate intensively. Due to the large amount of water vapor, it will not be possible to ignite the burner. For details on assembling and launching an impromptu hydrogen generator, see the video:

About Meyer's hydrogen cell

If you have made and tested the above construction, then by the burning of the flame at the end of the needle you have probably noticed that the performance of the installation is extremely low. To get more explosive gas, you need to make a more serious device called the Stanley Meyer cell in honor of the inventor.

The principle of operation of the cell is also based on electrolysis, only the anode and cathode are made in the form of tubes inserted one into the other. Voltage is supplied from the pulse generator through two resonant coils, which reduces the current consumption and increases the performance of the hydrogen generator. The electronic circuit of the device is shown in the figure:

Note. Details about the operation of the scheme are described on the resource http://www.meanders.ru/meiers8.shtml.

To make a Meyer cell, you will need:

- a cylindrical body made of plastic or plexiglass, craftsmen often use a water filter with a lid and nozzles;

- stainless steel tubes with a diameter of 15 and 20 mm, 97 mm long;

- wires, insulators.

Stainless tubes are attached to the dielectric base, wires connected to the generator are soldered to them. The cell consists of 9 or 11 tubes placed in a plastic or plexiglass case, as shown in the photo.

The elements are connected according to the scheme known on the Internet, which includes an electronic unit, a Meyer cell and a water seal (the technical name is a bubbler). For safety reasons, the system is equipped with critical pressure and water level sensors. According to home craftsmen, such a hydrogen installation consumes a current of the order of 1 ampere at a voltage of 12 V and has sufficient performance, although exact figures are not available.

Schematic diagram of the inclusion of the electrolyzer

Schematic diagram of the inclusion of the electrolyzer plate reactor

A high-performance hydrogen generator capable of ensuring the operation of a gas burner is made of stainless steel plates measuring 15 x 10 cm, the quantity is from 30 to 70 pieces. Holes are drilled in them for tightening studs, and a terminal is cut in the corner for connecting the wire.

In addition to sheet stainless steel grade 316, you will need to buy:

- 4 mm rubber, resistant to alkali;

- end plates made of plexiglass or textolite;

- tie rods M10-14;

- check valve for gas welding machine;

- water filter for water seal;

- connecting pipes made of corrugated stainless steel;

- potassium hydroxide powder.

The plates must be assembled into a single block, insulated from each other with rubber gaskets with a cut out middle, as shown in the drawing. Pull the resulting reactor tightly with pins and connect it to the nozzles with electrolyte. The latter comes from a separate container, equipped with a lid and valves.

Note. We tell you how to make a flow-through (dry) type electrolyzer. It is easier to make a reactor with immersed plates - there is no need to install rubber gaskets, and the assembled block is lowered into a sealed container with electrolyte.

Wet generator circuit

Wet generator circuit The subsequent assembly of the generator producing hydrogen is carried out according to the same scheme, but with differences:

- A tank for electrolyte preparation is attached to the body of the apparatus. The latter is a 7-15% solution of potassium hydroxide in water.

- Instead of water, the so-called deoxidizer is poured into the "bubbler" - acetone or an inorganic solvent.

- A check valve must be placed in front of the burner, otherwise, when the hydrogen burner is smoothly turned off, the reverse blow will break the hoses and the bubbler.

To power the reactor, it is easiest to use a welding inverter; electronic circuits do not need to be assembled. How Brown's homemade gas generator works, the home master will tell in his video:

Is it profitable to get hydrogen at home

The answer to this question depends on the scope of the oxygen-hydrogen mixture. All drawings and diagrams published by various Internet resources are calculated for the release of HHO gas for the following purposes:

- use hydrogen as a fuel for cars;

- smokeless combustion of hydrogen in heating boilers and furnaces;

- be used for gas welding.

The main problem that crosses out all the advantages of hydrogen fuel: the cost of electricity for the release of a pure substance exceeds the amount of energy obtained from its combustion. Whatever adherents of utopian theories claim, the maximum efficiency of the electrolyzer reaches 50%. This means that for 1 kW of heat received, 2 kW of electricity is consumed. The benefit is zero, even negative.

Recall what we wrote in the first section. Hydrogen is a very active element and reacts with oxygen on its own, releasing a lot of heat. In trying to split a stable water molecule, we cannot apply energy directly to the atoms. The splitting is carried out by electricity, half of which is dissipated in the heating of electrodes, water, transformer windings, and so on.

Important background information. The specific heat of combustion of hydrogen is three times higher than that of methane, but in terms of mass. If we compare them by volume, then when burning 1 m³ of hydrogen, only 3.6 kW of thermal energy will be released compared to 11 kW for methane. After all, hydrogen is the lightest chemical element.

Now consider the explosive gas obtained by electrolysis in a homemade hydrogen generator as a fuel for the above needs:

For reference. To burn hydrogen in a heating boiler, the design will have to be thoroughly reworked, since a hydrogen burner is capable of melting any steel.

Conclusion

Hydrogen in the composition of HHO gas, obtained from a home-made generator, will be useful for two purposes: experiments and gas welding. Even if we discard the low efficiency of the cell and the cost of assembling it, along with the electricity consumed, there is simply not enough performance to heat the building. This also applies to the gasoline engine of a passenger car.

ovent.com

do-it-yourself electrolyzer, drawings, getting at home, for a car