How to make heating in the dressing room from the stove. How to make heating in the bath in winter - options for effective heating systems

You can equip water heating in the bath yourself, starting from making a home-made boiler, laying out a wood-burning brick stove and ending with the installation of the “warm floor” system. The main thing is to clearly follow the technology at each of these stages.

Content:

The issue of heating the bath must be dealt with after insulation work, before interior decoration. In compact buildings, it is easiest to build a heater, the power of which is sufficient to heat the steam room, washing compartment and dressing room. In large rooms, it is necessary to install full-fledged heating using a pipeline.

Types of fuel for a bath with water heating

To simplify the task, you can bring water heating to the bathhouse from the house. In winter, you can maintain the optimal temperature in the building in this way. However, in this case, the equipment of a separate circuit is still required for its heating in the summer.

Water heating of the bath can be carried out on different types of fuel:

- Gas. In this case, to warm up the boiler, it is necessary to connect to the general gas supply system and install the appropriate equipment. But many settlements in our time are not gasified. And the use of liquefied fuel in cylinders is a fire hazard.

- Electricity. For heating in this way, it is important to correctly calculate the required boiler power. The main advantage is the possibility of installation without a chimney. The disadvantages include the high cost and the need for a three-phase network for a boiler with a power of 12 kW or more.

- Firewood. Such an oven is capable of heating all rooms with the highest quality. Wood is the traditional fuel for the steam room. However, the process of harvesting firewood and kindling the stove is quite laborious.

Liquid fuels are not economically viable and are highly flammable. Requires special precautions. Not recommended for bath heating.

After deciding on the type of fuel, select the appropriate stove. The market offers many production models of different quality in a wide price range. However, if you wish, you can build it yourself.

The most efficient and high-quality heating of the bath is possible with a wood-burning stove. Traditionally, a steel or brick structure is installed. In the first case, due to the large heat transfer and the thickness of the walls, the rooms warm up faster. The firebox of a brick oven takes more time, but the heat is stored longer due to the ability of the brick to accumulate it.

Making a water boiler for heating a bath

For these purposes, you can use ordinary cast-iron radiators M-140. We need 12 sections. Each of them has a capacity of 1.5 liters and an area of 0.254 m 2 . The total volume of the structure will be 18 liters, and the area will be 3 m 2.

To use it, you need to convert the radiator according to the following instructions:

- We take out cardboard strips between the sections.

- We prepare a mixture of drying oil and graphite. We impregnate the asbestos cord with it and lay it instead of gaskets. This will prevent burning at high temperatures.

- We wash each section with a six percent hydrochloric acid solution, and then with a large amount of plain water. This is necessary for cleaning from dirt and rust.

- We assemble the individual parts into one structure in the reverse order, using nipples with right and left threads on the sides for fixing. The sections will be attracted by the scrolling of the nipple.

- When the distance between them reaches two centimeters, we wind the impregnated cord and make the final tightening of the fasteners.

Wood-burning stove for a bath with water heating

It is desirable to consider a place for installing the furnace at the construction stage. Due to the heavy weight, an additional foundation is required for the stone structure.

We carry out work on the construction of a wood-burning stove for a bath with water heating in the following sequence:

- We dig a pit with a depth of about 0.7 meters. We fall asleep a sand cushion 15 cm thick, spill it with water and carefully tamp. From above we make a layer of broken brick or rubble.

- We install wooden formwork along the walls of the pit. We mount the frame from the reinforcement and insert it into the recess.

- Pour concrete, leaving 15 cm to the top.

- We dismantle the formwork and fill the resulting space with sand.

- We cover the upper part with a roll waterproofer in two layers. The best option is ruberoid.

- We check the horizontalness of the foundation. Small irregularities can be covered with intermediate dry brickwork.

- We make a solution of clay and water, the consistency of thick sour cream. With complete dissolution, add sand in a one-to-one ratio with clay.

- We wet the bricks with water and lay the first row tightly, checking the corners and horizontality.

- On the third row, we fix the blower door with a galvanized wire or steel strip.

- On the fourth - we equip the ash well.

- On the sixth - we finally fix the blower door.

- On the seventh - we install the grate. The size of the firebox must be calculated taking into account the installation of the boiler. On the first row of the firebox we form a special side and mount the corner. In the side walls we leave 2 openings for the outlet of pipes. Doors for the fuel compartment are best chosen from refractory durable cast iron.

- On the eighth row, we build a partition to connect to the chimney and continue this installation until the fourteenth, on which you want to install channels.

- We place at an angle halves of bricks from the fifteenth to the eighteenth rows. This will form the basis for the dividing wall.

- On the next row, we make a door for the steam vent and lay thin metal strips that connect the twentieth and twenty-first brick rows. After that, close the door frame.

- We begin to mount the chimney pipe from the 23rd row, forming channels for heat dissipation.

Please note that the wall inside the fuel compartment and chimney should be as even and smooth as possible. Every five rows you need to wipe the inner surface.

Installation of a boiler for water heating of a bath and piping

The cast-iron structure must be placed behind the firebox chamber. It will heat up not from the flame, but from the gas. To properly install the equipment, follow this procedure:

- We place a radiator on pre-made corners, observing a distance to the walls of about 5-6 mm. The gap will compensate for the thermal expansion of the structure.

- If the selected pipes for connection to the boiler have seams, then we additionally weld them before installation.

- We attach diagonally inch water supply and return pipes. In a place with a right-hand thread, we simply screw the product. On the left - we use a clutch with a drive and a nipple for fixing.

- We install the water supply pipe perpendicular to the floor at the top point, and equip the return line in the underground space and connect it from below. This is necessary for improved circulation.

- We close the two extra holes of the product with a plug.

- When welding pipes together, we remove the chamfer along the cut contour for high-quality filling with a welding seam of the entire thickness and reliable fixation of parts. If the steam room warms up infrequently in winter, then you can pour antifreeze into the system instead of water.

Installation of a water heated floor in a bath with water heating

Although this device will cost more, it is able to warm up the room as quickly and efficiently as possible. Heat goes around the entire perimeter of the room, and not from one source. In this case, the heated air rises.

You can equip underfloor heating in a bath with water heating yourself in this order:

- We level the surface, carry out insulation work.

- We lay aluminum foil on the rough coating, with a reflective coating overlapping upwards by 15-20 cm. We glue the joints with reinforced tape.

- We install a collector cabinet, cutting a hole of 0.6x0.4x0.12 meters at the surface of the flooring.

- We put supply and return pipes into it, fix metal shut-off valves to them using compression fittings.

- We connect the circulation pump and the splitter. The latter is best equipped with an automatic air vent system and a drain valve.

- Along the perimeter, we lay metal-plastic pipes with a diameter of 2 cm or more in a parallel or spiral way with a step of about 0.3 meters. For these purposes, we use clips and clamps. We observe the distance from the nearest wall - 7 cm.

- We connect one end of the pipe to the general heating system (supply manifold). We connect the second edge with a return device.

- We let in water at a pressure that is one and a half times the working pressure. If the system withstands, and the temperature is uniform everywhere, then we proceed to pouring the cement-sand screed.

The manifold cabinet assembly can be purchased from the respective retailers. Pipes must be selected from quality reputable manufacturers.

Watch a video about water heating baths:

Water heating in a bath is one of the most effective methods of heat supply. It is popular in large steam rooms. You can equip it yourself, but the process is time-consuming, requires strict adherence to the rules. And the combination of such a system with a high heat output of a wood-burning stove will allow you to maintain the optimum temperature in the room for a long time.

One of the problems that will need to be solved in the sauna planning process is related to the correct choice of the bath heating scheme. The heater built into the steam room is able to provide only a third of the heat demand in the bath, and even then most of it will go to boiling water and washing, therefore, without additional heat sources, heating the bath in winter can turn into a serious problem.

Possible options for heating the bath

With the advent of modern sauna stoves, the problem of heating a room has turned from a purely technical problem into an economic one. The owners of modern saunas and steam rooms, choosing a way to make heating in a bath, are forced to balance between efficiency and comfort.

The bath heating system is selected based on its design and available energy sources. Today, four main methods of heating a room are used:

- Sauna heating from a sauna stove. Depending on the size, it is possible to heat the interior space with boilers and stoves on wood or gas fuel;

- Use of additional electric convectors, installation of electric water boilers complete with radiators or underfloor heating system;

- Equipment in the utility room of the bath for an additional heating stove for wood, liquid or solid fuel;

- Connecting the bath to the heating plant or to the heating system of private housing construction.

It is clear that the choice of a suitable scheme is always made with the expectation of providing the required level of heating for the bath in winter. And it's not even the low temperature in the dressing room or locker room, the level of heating is directly related to air humidity and condensation.

Note! The approximate level of heat load in maximum cold weather should be at least 1000 W / h per m 2 of the steam room and 600 W / h per square dressing room and dressing room.

Most often, problems arise in wooden chopped buildings heated by the heat of the brickwork of the heater. Therefore, before you make heating in a log bath, you need to think about the ventilation device in the steam room and washing department.

Heating in the bath with the help of the main stove

A couple of decades ago, providing a comfortable thermal regime in the bath room was provided by the accumulated heat of the brickwork on the back side of the stove. The loading tunnel of the combustion chamber was taken out into the dressing room, and the furnace itself was built into the partition in such a way that the rear brickwork was divided in equal parts between the rest room, the locker room and the washing department.

In modern baths, brick ovens of much more modest size are built, therefore, more efficient cheap designs are widely used for space heating:

- Water heating from a gas or wood-burning sauna boiler;

- Built-in heating from a heat exchanger or a tank installed on the main stove of the bath;

- Boiler heating using a heat accumulator connected to a sauna stove.

In addition, in baths made of adobe blocks, adobe and unbaked bricks, heating is often used with the help of hot air flowing through the furnace registers through clay channels in the walls and underground of the room. The method is incredibly reliable and easy to operate, but requires highly skilled craftsmen. Used primarily in dry continental climates.

Bath heating with a fireplace

Using a fireplace stove is considered one of the most effective ways to heat a small sauna room in a country house or guest house. In this case, the sauna stove consists of two parts:

- A brick stove-heater with a combustion chamber, which is loaded with firewood from the steam room;

- Fireplace façade, attached to the heater and opening into the dressing room or dressing room.

The fireplace and the heater are combined into one brick structure, moreover, their chimneys are connected in one chimney. The large weight of the brick oven does not affect the quality of heating.

Important! The fireplace should be heated first, and only after the chimney has warmed up, you can make a fire in the furnace of the heater. Otherwise, the cinder from the fireplace will burn out in the steam room of the bath.

Organization of a water circuit using a boiler stove

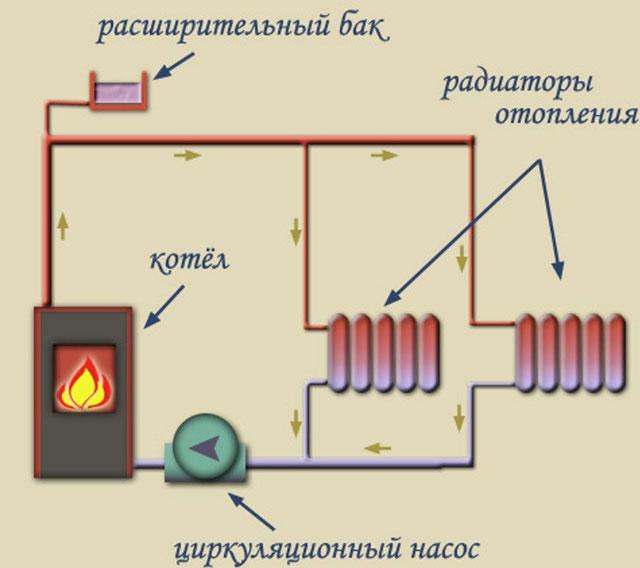

The simplest heating option involves the use of a special boiler model with a built-in water circulation circuit. For the organization of heating is enough:

- Install and connect the expansion tank, pipes and pump to the water circuit;

- Hang aluminum heating radiators in the dressing room and washing compartment.

It is clear that before doing heating in the bath from the stove, you will need to perform a simple calculation of heat transfer in each of the rooms. If the boiler is gas, then set a comfortable air temperature in the locker room or in the washing department. Automatic combustion is able to maintain the temperature in the water circuit with an accuracy of one degree.

Note! The main advantage of boilers with a built-in additional water jacket circuit is an unlimited amount of hot water that can be obtained for the needs of a home, summer house or summer kitchen.

Another thing is if the stove-boiler with a water circuit runs on wood or pellets. In this case, even installing an additional tank does not save, in order to set up the operation of water heating, you have to use a pump with a variable water supply capacity or put bimetallic thermostats on the radiators.

Scheme of heating the room from the stove

A water bath boiler is quite expensive, while the built-in heating circuit does not particularly affect the operation of the steam room, and it is used in the bath mainly in the cold season. From this point of view, the purchase and installation of a heating system for a bath looks economically unjustified, especially in a situation where the bath room has only a steam room and a dressing room.

In addition to the boiler method of heating water, in the steam room there is most often a second source of boiling water - a mounted or mounted tank, in which the liquid is heated to spray the backfill of the heater. Typically, 50 to 100 liters of water is boiled in such a tank. Is it possible to make bath heating from a tank?

A simple calculation shows that in a tank with a capacity of 100 liters, filled to the brim with boiling water, heat is stored in the equivalent of 8-10 MJ or 2.5-3 kW / h. If you use at least 80% of the energy, then this is enough to organize the heating of the dressing room from the sauna stove.

The heating system of the bath can be almost doubled if, instead of a built-in heating tank, a system with a heat exchanger built into the stove is used. You can extract heat from the furnace in a variety of ways:

- Install a system of tubular registers made of steel pipes in a brick stove;

- Mount a coil made of copper or alloy steel in the furnace;

- Use a structure of double tanks as the walls of the combustion chamber.

To ensure efficient heating of the bath, the size of the combustion chamber of the furnace will need to be selected based on increased productivity. Usually, a firebox for a stove with a water circuit is chosen for a single load of at least 2.5 kg of firewood.

Bath electric heating

The use of electricity to heat bath apartments is considered to be the most unprofitable way of heating. Despite the fact that the technical part of the issue - the purchase and installation of two or three heaters costs mere pennies, the consumption of electricity for heating the dressing room and rest room with the help of electric convectors is quite expensive.

Even more unprofitable and unsafe is the heating of the bathhouse with the help of infrared emitters. According to the owners, such a device can be hung in the vestibule of the bath above the front door, it is not economically profitable to heat the entire room with it.

The only economically justified way to heat a room with electricity is to use an electrode electric boiler with aluminum radiators or equipment in a heated floor. In this case, the cost of paying for consumed electricity is comparable to gas heating.

Heating with heat accumulator

A relatively new method of heating living rooms in private houses using heat accumulators is also gaining popularity for heating baths. Moreover, a huge tank with an alkali solution or paraffin melt is most often installed either in the basement of a building or in the nearest outbuilding. Bath for these purposes is best suited.

The heat accumulator is heated either by excess heat in a furnace or solar collector, or by electric heating at night. In this case, thanks to the reduced electricity tariff, heating costs are reduced several times, especially. if the bathhouse is located near the house. An even higher level of savings can be obtained if you solve the problem of how to conduct heating in the bath from home.

Heating due to external heat sources

In this case, we are not talking about heat pumps, although devices are already being actively sold in Europe that can provide heating for several buildings at once on the territory of one household.

The economic part of solving the problem is obvious:

- No need to buy expensive gas or electric boilers. Laying communications from the heating boiler in the house to the collector in the bath will cost an order of magnitude cheaper;

- There are no grounds for possible claims from the side of Energonadzor, fire and gas services;

- The larger the heating boiler, the higher its efficiency, therefore, the kilocalories of heat received from the home heating system will be cheaper than the energy obtained by burning gas in a low-power bath apparatus.

The only significant problem is the correct choice of the tie-in scheme in the heating circuit of the house. Usually, water heating in a private house is built in the form of a closed ring with convective or pumping coolant supply.

If you try to simply cut the pipe into the “hot” part of the collector of the house heating boiler, then due to the different hydraulic resistance in the pipes, a “stagnant” zone may form in one of the lines. Simply put, all the heat will either flow mostly into the bathhouse, or remain in the heating system of the house.

To ensure that stagnation and a complicated balancing procedure using throttle washers are avoided, an additional boiler with a built-in heat exchanger is used when connecting the bath. The tank is included in the heating system of the house, the internal circuit is connected to the heating pipes of the bath. The hot water accumulated in the boiler will be used as a thermal buffer, which will avoid freezing of the pipes of the main system in winter.

Heating in the bath is a personal matter for everyone. But in order for bath procedures to be a joy in winter, it should be comfortable indoors. Thanks to the heating in the bathhouse in winter, you can quickly heat up the rooms using a minimum amount of firewood, install plumbing and have a hot shower with an equipped bathroom.

Bath heating in winter

The classic heating of the bath is a metal or brick heater. Additional equipment is needed to maintain the air temperature in the steam room and in other rooms.

Some prefer water heating. With this type of heating, water floors or radiators are connected to the heating system of the house or to the heating plant.

Many prioritize electric heating because of its ease of use. You can always quickly heat a small room with a few electrical appliances.

Heating stove-heater

If the bath is small, then the heater is the best option. It will easily heat the room without additional sources of heat and cash costs. Its popularity is due to a number of advantages:

- ease of installation and maintenance;

- ease of operation;

- fuel availability.

There are also disadvantages:

- high fire hazard;

- release of combustion products;

- there is no way to automate the heating of the room;

- large weight and dimensions of the furnace.

Today, heaters run on a variety of fuels. These are firewood, gas, electricity, liquid fuel. The choice depends on the material wealth and technical capabilities of the equipment itself.

Heating by furnaces with heat exchangers

Such heating heats the room, provides it with hot water and generates steam. Heat exchangers are used in steam rooms, washing rooms, rest rooms, shower rooms, swimming pools, dressing rooms.

When designing a bath in this way of heating, the following are taken into account:

- the size and area of the room;

- stove features;

- weight of heating equipment;

- coolant volume;

- length and diameter of the chimney.

Heating can be connected to an expansion tank, to radiators, to hot water supply.

Many heat exchanger ovens are filled with antifreeze or water. The principle of operation is based on the natural circulation of fluid due to temperature differences. Some are equipped with an electric pump.

A warning! The heat exchanger must not be heated if the tank is not filled with water. In winter, drain the water from the system.

Electric heating system

This type of heating requires special attention to the electrical network of the room, since there will be a large load due to thermal electrical appliances. The wiring must be in perfect order.

It is necessary to take into account the wiring diagram, the wire cross-section and the total load on the power grid.

With this type of heating, you can use an electric boiler, an electric stove-heater, an electric convector, an infrared film. Infrared heaters are widely used.

Modern electric boilers are equipped with automation that maintains the temperature in the bath.

Such heating can be used throughout the year.

Gas heating system

Bath with gas heating - it's fast, efficient and economical. There are no unpleasant odors, no soot and soot. Gas equipment is compact, weighs little and does not take up much space. There is no need to think about heating water, it is heated with gas.

Advantages of a bath with gas heating:

- Cheap and environmentally friendly fuel.

- Easy maintenance and use of the device.

- Safety in use.

Important! When using a gas heating system, safety rules must be observed. The bath should be equipped with automation, which in an emergency will stop the gas supply.

Water heating system

A water heating system is a practical, convenient and affordable way to heat a bath in winter.

It quickly and evenly heats the room and automatically maintains the temperature. The heat carrier is water. The fuel can be electricity, gas, solid or liquid fuel. Heating equipment - boiler or stove.

Underfloor heating system

As an additional source of heat, it has become very fashionable to carry out heated floors in the baths. They are made in a rest room, steam room or washing room.

The heat carrier can be heated with wood. In this case, the power consumption will be approximately 45 watts for two circulation pumps.

It is not difficult to make such floors. The main thing is to choose the diameter of the pipes correctly, calculate the pump power and the resistance of the circuits.

Without fail, it is necessary to carry out two circuits separately: to the rest room and to the steam room with a washing room. It is necessary to put taps to regulate the temperature.

To increase the rate of water circulation in the system, you need to connect a hot water tank to the boiler with copper pipes with a diameter of 22 mm.

Advantages of a water heated floor:

- the heating system is located inside the floor;

- not only small, but also large areas are evenly heated;

- saving energy resources.

Warm floors can be water or electric.

Heating system from a heating main

Today, modern technologies make it possible to carry out heating from the house to the bathhouse. This takes time and financial costs. Coordination with the relevant authorities is required.

During such work, it is necessary to take into account the passage of groundwater so that the pipes do not end up in the water. The pipeline must be insulated. Put on a corrugation or a pipe of a larger diameter from above.

The closer the objects are to each other, the cheaper it will be to heat the bath in winter.

Alternative and mixed heating options

Such methods of heating a room are popular and practical. The best solution for mixed heating is the case when the bath is used infrequently. You can make heating in the bath from the stove and conduct electric heating.

Advice! If the bath is not constantly operated in winter, then it is imperative to drain the water from the boiler, water heater, pipes, toilet bowl (if any). This will save you from unnecessary problems.

Alternative heating sources can be conditionally divided into main and additional groups. The main ones completely heat the entire room. And additional ones support the work of the main heat source.

An alternative heating option can be considered a diesel fuel boiler. It is mandatory to install it in a separate room due to the specific smell of fuel. It is important to think about the place of storage of diesel fuel.

You can use pyrolysis heating boilers. In them, the fuel burns out for a long time and almost completely. But the disadvantage of such a boiler is the high cost and difficulty in operation.

If the oven is brick, then the heating of the bath from the sauna stove can be carried out in the steam room. This option is effective if the bath is rarely used and the area is small.

Alternative heating options can be heat pumps, electric convectors, solar collectors, water heating.

All systems can be divided into two types of heating:

- equipment with forced circulation;

- equipment with natural circulation.

With forced circulation, the coolant moves thanks to the pump. It maintains the required temperature and pressure in the system. It needs electricity to work.

Natural circulation includes a boiler, radiators, expansion tank and pipes. We need a competent layout of pipes, the correct calculation of their slope. The disadvantage is that the expansion tank must be at the highest point.

How to make heating in the bath

Heating in the bathhouse is necessary to provide comfort.

One type of heating is automatic. Separate heating can be provided by electric convectors or electric boilers, as well as gas boilers. All of them can work offline. You can set it so that the room has a slight positive temperature. This will allow you not to drain the water from the toilet bowl, pipes, electric boiler.

There is a downside to this system. Since it is autonomous, you may not notice that a failure has occurred and the temperature may drop below zero. Therefore, you need to install a temperature sensor with a signal.

How to conduct heating in the bath from home

You can install both gas or electric boilers, as well as stone or metal stoves. But these are all rather complex structures.

To heat the bath from the house, you can lay a heating main there. Install radiators in your home. Such a system will work from heating in the house.

Sauna heating from a sauna stove

The easiest heating method to manufacture, operate and maintain is heating a bath from a sauna stove. The stove is installed directly in the steam room, and the firebox is in the dressing room.

Brick ovens keep the temperature for a very long time, but they need to be warmed up for at least 5 hours. And it takes even more time to heat the bath in winter.

High cost is another disadvantage. It is very difficult to fold such an oven on your own. Need help from an experienced baker.

Heating of the dressing room from the sauna stove

In most cases, a classic bath is heated by one heat source. The stove is installed in the steam room so that all rooms can be heated. A water tank is placed near the washing room.

It is very important that each element of the furnace is made of refractory material. Therefore, it must be built of brick. Such an oven will take up a lot of space and be large.

An ideal option would be a stove with a tank and an open heater. The firebox is equipped with a register, the lower edge of which is located 50 cm above the register. It will prevent premature boiling of water.

Is it possible to make heating from a tank

To install a heating system from a tank, you need to know its specifics of operation and operating rules. It is necessary to take into account the volume of the room and the power consumption.

There are mounted and built-in tanks. There are also attached tanks - a container of water is placed on top of a heated oven.

Comment! You can use the already created heat: a tank is hung on the chimney, the water is heated, and the temperature there can reach 500 degrees.

Such methods do not supply hot water to the shower. This can be done with portable water tanks. The heat exchanger is placed in the furnace, a tank is hung next to it or in the attic. The system is connected by pipes through which water will flow. Thanks to the heat exchanger, it heats up and is fed through the tank into the shower. Such a heating system is simple and efficient.

Mounted tanks are hermetic containers with a lid and a tap for draining water. Attached to the wall with metal hooks. Made from stainless steel.

Attached water tank - an inclined pipe sealed at the end is welded into the furnace. The other end is at the bottom of the tank. Cold water rises through an inclined pipe, where it is heated to a boil. Hot air bubbles carry heat.

How to make heating in a log bath

Three types of heating are installed in wooden houses: water, electric and air. Each has pros and cons.

The most popular type of log house heating is water.

- Profitability.

- High heat capacity.

- Difficulty in installation.

- The need to constantly monitor the heat generator.

- In winter, be sure to drain the water from the heating system.

Such heating systems are:

- with bottom or top wiring;

- passing or dead-end;

- one-pipe or two-pipe;

- vertical and horizontal;

- with pump or natural water movement.

Two-pipe systems are less aesthetic than one-pipe systems.

Electric heating has several advantages:

- The level of heat supply is easily regulated.

- Small dimensions of heating devices.

- Heating is environmentally friendly and silent.

Air heating has only one plus - high penetrating power.

But there are many more cons:

- large stoves and fireplaces;

- very low heat transfer;

- uneven distribution of air in the room;

- expensive heating systems.

Before installing systems, it is necessary to weigh all the advantages and disadvantages and, possibly, consult with a specialist from the industry.

Conclusion

Heating in the bath is the most important thing to pay attention to during construction. Banya is one of the best places to relax, where you can have a good time with family or friends. If it is warm and cozy there, then the rest will be soul and body.

The key to a good bath is a properly folded stove. This is perhaps the most important attribute of the bath. It is this heating in the bath that will allow you to heat the room, heat the water for bathing and create steam in the steam room. To heat a large bath, you can install a heating stove. If you don’t know how to make heating in a bath, but decide to build a steam room, a stove-heater is the best option.

Peculiarities

In summer cottages, they build family-type baths for themselves, in which one stove-heater is enough. This type of heating in the bath will take over all the basic functions. It is precisely with this that it is important to observe all the subtleties during the construction of the furnace. The stove-heater is better to make a small one. This will save space. At the same time, its heating time will be minimal, and it will give off heat as long as possible. But the most important thing is what fuel it will be heated with. It is best that the fuel is cheap. Popular - water heating baths.

Steam room - the main room of the bath

High heat capacity will allow you to get good steam for a long time. In addition, dry heat will be used to heat the room and water for washing. To make everything suit you, when making heating in the baths with your own hands, take into account the ratio of the size of the furnace, the room and the purpose of the bath. Make sure that your stay in the baths is as safe as possible for you and your family.

Think over to the smallest detail what materials you will use in the construction of the bath and stove so that they are not flammable. Responsibly approach the issue of ventilation. Whether it is gas heating in the bath or electric - this will allow you not to burn out from combustion products.

The principle of operation of the furnace

Let's talk a little about how the bath heating system will give off heat to the outside. If the heat radiation is maximum, you risk overheating or getting burned. Also, excess heat adversely affects the condition of the skin. In order for the conditions of stay in the bath to be comfortable, the stove must give off heat according to the principle of convection. Hot air comes out of the furnace, and cooled air is supplied.

To achieve this result, the temperature of the furnace walls will be lower. But fold the walls of the bath from materials that will reflect infrared rays as much as possible. Heat accumulates well in the wall and in the stone backfill. In order for the furnace to give off heat for the longest possible time, build its walls thicker.

Types of ovens

Kamenka stoves, which are used for heating baths in winter, can be divided into two categories according to the type of work: permanent and intermittent.

A continuous furnace is characterized by a small wall thickness and a small volume of stones. This type of stove has the ability to regulate the temperature both independently and automatically. In this case, the maximum temperature reaches 350 degrees. To heat this type of stove, it is enough to connect it to electricity. Gas is also suitable as a fuel.

If you decide to use electric bath heating, you can regulate the current strength in the heating elements yourself. Do not forget that when installing the oven, you must install a protective automatic system. If the wall temperature exceeds the permissible values, heating the bath with electricity will automatically stop the supply of electricity.

Also, stoves-heaters of constant action can be heated with coal or wood. Whatever you use to heat stoves, whether it is water heating in a bath, remember that it is important to separate the combustion chamber and smoke channels from the backfill.

To do this, you can use a steel sheet or lay a cast iron tile. Thus, you will prevent the penetration of combustion products into the bathhouse. It is also an excellent protection for stones from soot deposits. The latter, in excess, pollutes the air in the bath.

Ovens-heaters of periodic work are represented by thick masonry and a large volume of bricks. Thick walls will protect the surfaces of the stove from overheating, and for a long time the stove will give off heat.

Such heating in the bath allows you to heat the lower part of the furnace up to 1100 degrees. Working at such a high temperature, there is no soot settling as it burns. To save fuel, use the principle of "black" combustion. In this case, the smoke gases pass through the bath. This type of heating is very dangerous. The surface of the furnace and walls is covered with soot. As for the “white-style” version of the firebox, the firebox compartment is covered with a damper. It is allowed to open it after complete combustion of the fuel.

The most ideal fuel for how to make heating in baths can be firewood. It is not advisable to resort to the use of coal for heating. It is rather difficult to sharply reduce the temperature, which leads to destruction of the internal surfaces in the furnace. And this is a safety violation.

To obtain economically advantageous use of fuel, it is important that it burns completely.

The shutter is closed during combustion, special attention is paid to the air supply. When it enters, water vapor and carbon dioxide are formed. If there is no air supply, soot deposits form, resulting in low heat output. The risk of poisoning by combustion products increases. It is also possible to increase the heat transfer coefficient by heating a larger surface. It is necessary to heat the stove-heater until the walls are heated to the maximum temperature, and dry steam begins to give off.

What are stove stoves? Here are some of their designs. There are solid fuel stoves that are heated with coal and wood. Liquid fuel, kerosene or fuel oil is suitable for them as fuel. There are models of gaseous fuel stoves. For their work, you need to have liquefied or natural gas - heating the bath with gas. Also electric ovens.

In order to maintain a comfortable temperature regime in the main rooms of the bath and provide hot water, it is important to properly organize heating in the bath from a stove located in the steam room, or use alternative sources. At the same time, each owner of the bath will be able to make an autonomous heating system on his own, without involving third-party help.

The need for additional heating

The classic option for heating a steam room for bath procedures is a brick or metal heater. At the same time, additional equipment is used to maintain the set air heating temperature both in the steam room and in other rooms.

It is impossible to provide fast and uniform heating of the dressing room and rest room from the sauna stove.

And if in the summer this does not cause problems, then in the winter a similar situation can lead to a decrease in comfort when organizing a bathhouse holiday. In this case, all the heat produced will be accumulated in the steam room, and other rooms of the bath will remain unheated.

Installation of additional heating equipment will ensure the maintenance of a comfortable temperature necessary for a long stay in the dressing room.

Heating stove-heater

For small-sized baths, the traditional heating option remains the current option. In this case, it is enough to purchase or manufacture a heating unit of the required power.

The calculation of the power of the equipment is determined by the formula: 1 kW of power per 1 sq. m of premises. To ensure a comfortable stay of visitors in the steam room, an additional reserve of thermal power from 35 to 55% is taken into account.

The popularity of the heating heater is due to the following advantages:

- ease of installation and maintenance;

- availability of operation;

- using available fuels.

Giving preference to the sauna stove, do not forget about some of the disadvantages of the device:

- impressive dimensions and weight;

- inability to automate the process of space heating;

- high fire hazard;

- formation of fuel combustion products.

Modern heaters run on wood, electricity, liquid and gaseous fuels. The choice of a suitable option depends on the financial capabilities and technical capabilities of the equipment.

To ensure efficient heating of the room, the heating of the bath from the stove in the steam room is done as follows: the firebox is placed in the dressing room, the heater in the steam room, and the tank with warm water in the washing department.

Heating by furnaces with heat exchangers

At the design stage of heating equipment with a heat exchanger, the following data are taken into account:

- the dimensions of the building and the area of \u200b\u200bthe premises;

- design features of the furnace;

- weight of heating equipment;

- number of heat exchangers;

- coolant volume;

- length and diameter of the chimney.

The following options for connecting heating equipment using pipes are possible:

- to the expansion tank for hot water supply in the washing compartment;

- to heating radiators installed in functional rooms;

- to hot water supply and water heating system in the main premises of the bathhouse and residential building.

Heating furnaces are equipped with internal and external heat exchangers. The inner element is located in the furnace, the outer element is located around the chimney.

Electric heating system

Electric heating is the simplest and most affordable option for organizing an autonomous bath heating system. When organizing it, it is worth considering the electrical wiring diagram, the total load on the network and the cross-section of wires for high-quality installation work.

The electric heating system provides for the use of the following types of equipment:

- electric stove-heater;

- electric convectors;

- infrared film;

- electrical heating cables.

Modern electric boilers of low power are equipped with automation capable of maintaining a given temperature regime in bath rooms. To heat the bath, it is allowed to use induction, electrode and stepped boilers with heating elements.

The electric heater for a bath can be used as the main and additional source of heating. If possible, it is most convenient to use electric convectors. As in the case of boilers, convectors are equipped with thermostats to maintain the optimum temperature in automatic mode.

The electrical system can be operated all year round without the need for preparation and storage of fuel material. A significant drawback is the high consumption of electricity.

Gas heating system

When connected to a gas main, heating a bath with gas is the fastest and most efficient version of the system.

The system has two implementation options:

- traditional heater equipped with a gas burner;

- gas boiler with installation of heating radiators and water pipes.

The undoubted advantage of such heating is the absence of unpleasant odors, the formation of soot and soot. At the same time, gas equipment has a compact body, low weight and does not require much space during installation. The power of a standard boiler reaches 45 kW, which is enough to heat a room up to 280 square meters. m.

Water heating system

A practical and affordable way to organize bath heating in winter is to install a water system.

Water is used as a heat carrier, gas, electricity, liquid and solid fuels are used as fuel, a furnace or boiler is used as heating equipment.

Water heating provides for fast and uniform heating of bath rooms with the ability to automatically maintain the set temperature.

There are the following options for arranging water heating:

- Radiator heating. Provides for laying pipes along the walls, to which water radiators or convectors of the appropriate size and power are connected. Hot coolant from the boiler moves inside the system, providing space heating.

- Floor heating. Its principle of operation is similar to that in the previous version. The only difference is that the installation of pipes is carried out in a concrete base after its preliminary insulation and waterproofing. This design is of a non-separable type, therefore, it requires compliance with the installation technology.

Underfloor heating system

Modern floor heating systems are represented by electric and water. Water floors are an economical and affordable way to heat rooms, requiring high-quality installation, since it is quite difficult to repair such a system.

To heat a rest room, dressing room or washing room, it is enough to install underfloor heating. All work can be done by hand. To do this, it is necessary to select pipes of a suitable diameter, calculate the operating resistance of the heating circuit and the required pump power, taking into account the area of \u200b\u200bthe room.

Underfloor heating can be combined with radiator, electric and air heating.

Heating system from a heating main

A private bath can be directly connected to the central heating main. To organize a similar option for heating the bath, you will need to install an additional circuit.

The connection of the circuit to the heating main is carried out in accordance with the design documentation and permits obtained from the relevant authorities.

The choice of such an option is fraught with some difficulties:

- the likelihood of accumulation of groundwater in places where pipes are laid;

- the need for additional insulation of the heating main;

- the need for professional installers.

Alternative and mixed heating options

Alternative options for heating the bath are becoming in demand. These include the following types of equipment:

- heaters - ceramic and infrared;

- boilers - pyrolysis, pellet, diesel, long burning;

- baseboard and ceiling heaters.

In cases where the bath is rarely used, a good option is to equip a mixed heating system: a wood-burning stove combined with electric heating; pellet boiler with electric convectors. One type of equipment provides space heating for bathing procedures, the other - hot water supply and additional heating.

Combined bath and house heating system

If the residential building is connected to a central heating system, it is recommended to install auxiliary equipment for heating the bath.

Thus, the heating main from the house to the bathhouse is a practical and economical way of heating residential and functional premises.

In this case, the connection of the bath to the heating system from the house is carried out through insulated pipes laid underground. In the bath, they are connected to heating radiators or convectors installed in all functional rooms. A sauna stove is used to heat the steam room and the washing department.

With a small distance from the heating equipment installed in the house to the bath room, heat losses in such a system are insignificant.

In this case, the heating main of a residential building can be used for additional heating of the bath, helping to maintain a comfortable temperature regime in the winter. This will eliminate the possible freezing of sewer, water pipes and buildings.

The choice of a suitable heating system depends on the design features of the bath and the financial capabilities of the owner.

Some owners prefer traditional electric or wood-burning heaters, which provide gentle and even heating of the premises. Others choose combined systems or advanced heating technologies.

But if you know how to make heating in the bath, following the rules and recommendations, the operation of the building is possible throughout the year under any climatic conditions.

What else to read

THE LAST NOTES

- Amber extraction method in Belarus

- “Soon products from amber will arrive on store shelves”: trial amber mining has begun in the Brest region

- How to open an IP in Belarus

- Is it necessary to pay contributions to the social security budget for an employee who is on unpaid leave?

- What to give a man after parting