Sofa for giving do-it-yourself drawings. DIY sofa

The sofa is the most important part of the interior. It is he who is the hallmark of every home, so he needs to be beautiful, reliable, practical. But the models presented by stores are often unusually expensive. The best solution is to create this piece of furniture yourself, which will save a huge share of the family budget.

In addition, for the sake of repairing a sofa made by yourself, it makes no sense to call the master. Knowing his device, it is easier to fix the breakdown yourself.

Comparing a photo of a do-it-yourself sofa and a purchased one, it is sometimes difficult to find significant differences in quality. By strictly adhering to the instructions, anyone can make a first-class product with their own hands.

This will require the following tools:

- jigsaw;

- special stapler for furniture;

- screwdriver or drill;

- grinder (a simple planer will do);

- sewing machine;

- sharp knife and scissors;

- roulette.

Types and drawings of sofas are varied, but the main components of the product always remain:

- frame;

- mattress frame;

- back;

- side parts;

- stuffing;

- fabric upholstery.

To make them you will need:

- wooden bars 40-50 mm in cross section;

- plywood with a thickness of 5 mm;

- stuffing (foam rubber, holofiber, batting);

- furniture belts (optional);

- textile material (batting, synthetic winterizer);

- furniture fabric;

- strong thread for stitching upholstery;

- screws, corners, self-tapping screws.

The instructions for assembling the sofa are simple. The main thing here is the sequence of actions.

frame

Made from long bars. To give additional rigidity, plywood, chipboard, OSB and other sheet materials are used.

All this is fastened with self-tapping screws, screws and corners. They can be lubricated with glue before being screwed in, having previously drilled holes. For convenience, you can first connect the parts with glue.

Mattress frame

It is made from a solid sheet of chipboard or from fastened boards with a binding of furniture belts. It is not difficult to make it: first they are fastened with a stapler vertically, then the belts are intertwined with them and fixed horizontally (perpendicularly). Thanks to the binding, this piece of furniture will be perfectly springy.

Back and sides

Usually hollow inside. At the back, the frame is sheathed with a sheet of plywood and covered with a cloth, fixing it with a stapler. The ends are connected to the front side. With the help of metal corners, you need to fix the back on the base.

You can give it a sloping shape, adjust the slope as you wish. The sides are made in the same way. Then, all the sharp ends of the resulting base are sanded with a grinder or planer to avoid rapid wear of the upholstery.

pasting

It is most convenient to use high quality foam mats, in order to avoid the appearance of holes on the surface, with a density of 35 kg/m3. Having measured the pieces of the required size, you need to paste over the back from above and in front, the side parts from the inside, the plane over the binding.

The ends of the foam rubber can be fixed with a stapler. After the glue dries, these elements are wrapped in batting or synthetic winterizer in order to achieve volume and smooth out irregularities.

Upholstery

It is better to sew covers according to patterns already prepared in advance. When this is not possible, you can, instead, apply the fabric to different elements and immediately stitch or make it easier and tighten it by turning it at the corners, but this method is not reliable. It is better to entrust the matter to professionals and contact the studio, where they will do all the work for you.

After all this, the easiest thing is to assemble. It will take only 2-3 days of diligent work.

When assembling a sofa with their own hands for a summer residence, people want to use any materials at hand at no particular cost. Then, cheap or unnecessary parts can serve as a replacement for expensive ones. The result is a combination of original design, style and functionality.

For example, you can take wooden pallets. They are sold for pennies in the construction markets, for example. Used pallets should be thoroughly cleaned and washed. Then, even new panels should be sanded, if necessary treated with a water-repellent primer or painted.

It is not at all difficult to assemble a sofa from furniture panels. You just need to cut them with an electric jigsaw, measure the appropriate sizes, and fasten them with self-tapping screws. After, cover with paint and varnish and allow to dry. As a result, it remains only to make soft seats.

An unusual design move will be its manufacture from an old, outdated bath. To do this, remove the legs from it, clean the surface of the paint, cut off one wall with a grinder and grind the bumps.

The whole product is painted, the legs, processed separately, are returned to their place. It remains only to attach the seat and, if you want, trim the walls with soft components.

DIY sofa photo

Properly equipping a recreation area in a small living space will help corner furniture. It fits perfectly into the geometry of the room, preserves the maximum usable area, providing enough space for guests. You can save money on buying furniture of a similar configuration if you assemble a corner sofa with your own hands, while demonstrating not only skills in working with various materials, but also the ability of a designer. The main thing is to be extremely careful in your work, not to rush, and the result will please you with beauty and durability.

Assembling a corner sofa with your own hands, with the appropriate tools and materials, will not cause difficulties even for novice craftsmen. Such upholstered furniture will help to zone the space of the room. Equipped with spacious drawers, corner sofas will accommodate a lot of household items.

When considering whether it is worth spending time looking for the right model in the store or is it easier to build a sofa with your own hands, we pay attention to the following points:

- hand-assembled furniture always fits into the interior of the room, ideal in size;

- the choice of upholstery colors does not depend on the range provided by the manufacturer;

- having independently made a soft corner, you can minimize costs;

- when assembling a kitchen corner sofa with your own hands, you can personally check the quality of the product so as not to have doubts about its strength and durability.

The main plus of assembling a soft corner sofa with your own hands is aesthetic pleasure, a sense of pride in the work done. During the production process, you can feel like a real designer and acquire useful skills. Positive emotions will be strengthened by rave reviews from others.

Materials and tools

To save time and money, a detailed diagram of the arrangement of a corner sofa will help. It is also recommended to make a list of necessary materials and tools in advance. In the process of creating furniture, you may need:

- timber of coniferous trees (used for the frame);

- plywood (preferably birch) is needed for sheathing the base;

- Fiberboard is useful at the stage of installing the bottom and assembling storage boxes;

- laminated chipboard is most often used for the manufacture of armrests;

- soft materials (foam rubber or synthetic winterizer) are indispensable when stuffing the back of a sofa or pillows;

- fabrics for upholstery (dense fabrics impregnated with special water-repellent and protective compositions from excessive pollution);

- fasteners (corners, screws, nails);

- sliding mechanisms for boxes;

- furniture legs (it is more convenient to use elements on wheels);

- consumables (threads, glue).

One of the important points in the production of a corner sofa with your own hands is the correct selection of the necessary tools:

- saw - for cutting large wooden elements;

- a screwdriver, without which it is very difficult to quickly assemble any structure;

- sewing machine (preferably electric) - for sewing covers;

- a furniture stapler that allows you to firmly fix the fabric in the right places.

Depending on the complexity of the design, the minimum list of necessary devices can be replenished in the course of work.

furniture fittings

Upholstery fabrics

Drawings and diagrams

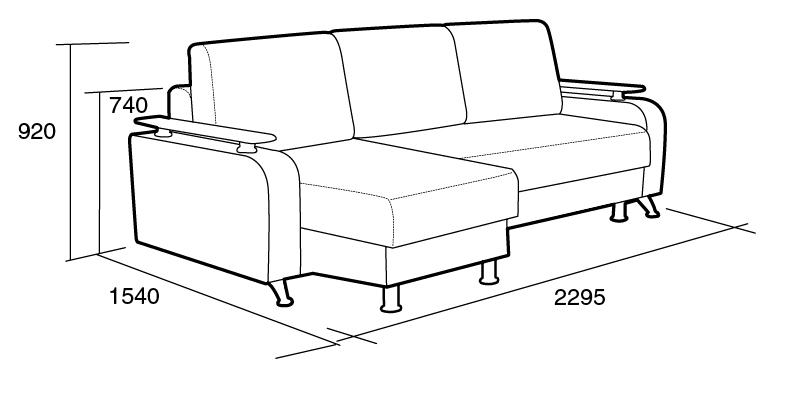

Properly drawn up drawings and diagrams for assembling a corner sofa with your own hands determine the quality of the final result. Sketches should be extremely simple and understandable. The basic principle is to describe the size and location of all the details of the future furniture. After the drawing of the future soft corner is drawn, a detailed layout of all fasteners, reinforcing parts, partitions, and, if necessary, drawers, is signed.

To do everything right, some recommendations from experts will help:

- when choosing the dimensions of furniture, it is important to measure in advance the place where it will be installed;

- first of all, a sketch is drawn, on which the length of the two halves of the sofa, its depth and the height of the backrest are necessarily indicated (this parameter can be arbitrary);

- the width of the sofa frame is calculated as the difference between the total length of the two halves and the depth.

The main points that are taken into account when creating a sofa drawing:

- back angle;

- the dimensions of the entire structure and its individual parts;

- the need to install folding mechanisms;

- the need for arrangement of storage compartments;

- sofa leg height

A secret from a professional: for the convenience of reading drawings and diagrams, when creating them, it is necessary to use different colors for each material.

For example, the base of the timber is shaded with yellow, the surfaces of chipboard are gray, the places of upholstery with foam rubber are pink. The scheme of the direction of tightening the screws is drawn with red arrows. This will help you quickly navigate and significantly reduce time costs.

Step by step instructions for making

Consider step by step how to make a corner sofa with your own hands. In accordance with the previously drawn scheme, the parts must be numbered and laid out as they are introduced into work. The smallest elements must be set aside separately from large parts. Sawing timber, fiberboard and chipboard panels can be done independently, but it is much easier and faster to order work from professionals. The assembly begins with large parts, gradually building up small elements on the base.

All components are connected with screws. To enhance strength, each part is first glued, and only then the two parts are pulled together.

Wireframe creation

The assembly of the sofa begins with the creation of a frame from a bar. Two long and two short blanks are connected into a rectangle. After the beam is fastened with self-tapping screws, metal corners are attached at the corners. Additional transverse supports are fixed in the center of the backrest. Thus, the strength of the base of the sofa is achieved.

The bottom of the corner sofa box is sewn up with a fiberboard sheet of the appropriate size. To fix the material, special small furniture nails or a stapler with staples are used (which is much easier, faster). The second half and corner insert are made according to the same principle. After all three parts of the base of the corner sofa are assembled, they are fastened together with bolts and nuts.

A washer laid in front of the nut will help protect the wood from damage by metal fasteners.

Next, we proceed to create the frame of the back. To do this, you need six bars, the same size, with a cut at an angle relative to the level of the seat. The skeleton of the structural element is assembled similarly to the base frame. It is important that all the details are mirrored to the base elements of the lower part. The back frame is fastened at the junction of the beam along the bottom and in the middle. The finished piece of furniture is screwed with self-tapping screws, after which the facade is closed, cut to size, with a sheet of chipboard or plywood. The upper end is covered with a piece of wood cut at an angle.

Next, seat loops are fixed to the frame (at the rate of three pieces for each element). The hinges are fixed with self-tapping screws at the junction of the side board and the peppered beam. They fix sheets of fiberboard, which will later become the basis for soft folding seats. The inside of the sofa will be a convenient storage place for various household items. The final step in assembling the frame is the fiberboard sheathing of the back and the installation of furniture legs around the perimeter of the corner sofa.

Assemble the frame

Sew up the bottom of the box with a sheet of fiberboard

Fix the seats and niche

It is not difficult to upholster the frame of a corner sofa if you strictly follow the following recommendations:

- the thickness of the foam rubber for the back and seat must be greater than for the armrests (at least 10 cm);

- before cutting, measurements are carefully taken;

- in order not to get confused, it is better to immediately glue the cut-out piece of foam rubber to the right place (we use ordinary PVA glue);

- you can give the desired bend, the shape of the soft part by cutting off the thickness of the foam rubber in certain areas;

- if you want to make a beautiful bend of the back, you can use twine and small pieces of foam rubber, laying out soft material in the right places and clamping it with twine, forming the necessary relief;

- before the fabric upholstery stage, it is better to cover the foam rubber with a layer of agrotextile.

No need to throw away the foam rubber scraps. From them, you can cut small parts of soft skin that are suitable in size.

upholstery fabric

A do-it-yourself pattern of covers for a corner sofa consists of separate elements - for upholstery of seats, sides, facade, back. Most often, when assembling a corner sofa for a kitchen or living room with your own hands, use the following fabrics:

- Matting is a very durable, abrasion and dirt resistant material that allows you to create a surprisingly pleasant to the touch, soft surface. Its undeniable advantage is its durability. Having upholstered furniture with such a fabric, you can forget about changing covers for many years. Gunny will report a high density index, keeps its shape well, does not wrinkle.

- Cotton fabrics attract with naturalness. They pass moisture and air, differ in brightness of coloring. But choosing such covers for a corner sofa, you need to be prepared for their frequent replacement. They quickly become unusable, rubbed, lose color. If the corner sofa is going for the kitchen, it is better to refuse natural fabrics of this kind.

- Flock is a good option. Delicate, velvet to the touch, the fabric stands out for its practicality due to nylon and nylon threads in the composition, it is resistant to dirt and sunlight. When assembling a sofa for the kitchen with your own hands with flock upholstery, you can be sure that even after a couple of years the covers will look the same as on the first day.

- Leather is an expensive material that allows you to create very beautiful, practical furniture. Leather covers for a corner sofa are not only a way to keep the original look for as long as possible (do not fade, do not wear out, easy to clean), but also an opportunity to add elegance to furniture.

Having measured the sofa, we make a pattern on paper. We redraw the pattern on the fabric and cut out the details (with an allowance for the seams). To make the appearance of the upholstery neat, the textiles for the covers are ironed well in advance. The cut material is thrown onto the foam rubber upholstery and fixed with a stapler. For lovers of comfort, coziness, do-it-yourself corner folding sofa can be supplemented with soft pillows sewn from the same fabric as the main upholstery.

The sofa in modern apartments is the most important design element. Often, for good quality furniture that matches the interior in color and shape, retail stores set a prohibitive price. Making a sofa with your own hands is much cheaper, and its manufacture will not cause difficulties.

Materials used

Depending on the desired model of the created piece of furniture, the place where it will be installed in the future and its purpose, you can choose completely different materials. To make a simple sofa, you can use several wooden pallets or pallets. Furniture from them is made quite simply, it is cheap and today it is at the peak of popularity. One has only to supplement the resulting pallet sofa with soft pillows, and it will turn into an excellent resting place for a Loft-style room or become an indispensable piece of furniture for installation on the veranda of a village house.

The material for the manufacture of another of the simplest and most cost-effective options for a homemade sofa can be the most ordinary cardboard. Old cardboard boxes, for example, from household appliances, pieces of bookbinding cardboard, corrugated cardboard - everything can be used. The main difference of such a sofa will be that in this model not a single nail and screw will be used, the parts of the sofa will be fastened together with the help of carpentry glue. Since cardboard is quite easy to cut, you can get furniture of any shape and size. In addition, such a design will weigh less than a sofa on a full-fledged wooden frame.

Wooden boards as a material open up a huge field for creativity. Of these, you can create a full-fledged folding sofa with any chosen mechanism, make both a frameless version and furniture on a strong wooden frame, create a comfortable sleeping bed or just a place to hang out with friends. The abundance of types of wood offered for sale in specialized stores and the thickness of the boards used allows you to adjust the weight of the finished product, its strength and functional features. From wood, you can also make interesting non-standard models of furniture for relaxation. So, you can easily make a hanging sofa swing. It can be a great option, for example, for a gazebo or veranda. Slow rocking and soft pillows will create a relaxing effect and give you a real rest from pressing problems.

You can also make a completely new piece of furniture by restoring the old frame. Sanding and impregnating the wood with a special solution will help renew the old wood material and create the basis for a future project.

In addition to the frame material, upholstery material may also be required, depending on the model being made. Here dense upholstery materials, which are most often used for the production of upholstered furniture, will come to the rescue. The choice will be determined by the interior design, the amount that the master will be willing to allocate for materials and the functions assigned to the sofa.

The most popular upholstery materials:

- Leather- one of the most durable and durable materials, gives sophistication and solidity to manufactured furniture, however, it has a high cost and requires special tools to connect parts.

- eco-leather- a material that has all the advantages of genuine leather, among the advantages, one can single out a lower cost and a larger range of colors.

- Leatherette- the cheapest analogue of leather, quite durable, environmentally friendly and stylish. Among the minuses is the fear of mechanical damage.

- chenille- a comfortable fabric for craftsmen who do not have much experience in sewing, as it does not stretch or slip, but at the same time it has a high degree of wear resistance.

- Velours- soft and pleasant to the touch material, also refers to materials that are convenient for sewing, but it also has a significant disadvantage - stains are difficult to remove from such a fabric and it is very capricious in care.

- Tapestry- dense and durable double-sided material with a pattern. You can buy it in absolutely any fabric store, but you need to remember that a sofa with such upholstery does not tolerate direct sunlight, as the fabric fades quickly enough.

- Jacquard- durable, pleasant to the touch material, reminiscent of silk. Has a characteristic luster. When choosing, it should be borne in mind that when stitching, the material can slip and you will have to make some efforts to make the product beautiful and neat.

When choosing a material, it is also worth considering how the upholstery will be sewn together. If you plan to sew a cover on a conventional sewing machine, and not on an industrial one, it is more appropriate to choose thinner fabric materials. When fastening parts made of thick furniture leather or leatherette on a machine that is not designed for heavy materials, there is a risk that the machine will not sew them or even break.

A homemade sofa, if the idea suggests it, should have a soft comfortable seat. To do this, you need a special material - a filler. As it can be used:

- Foam rubber- one of the softest furniture fillers, besides, it has a low cost and is available for purchase in retail stores.

- Polyurethane foam or polyurethane foam- a relative of foam rubber, however, it has a denser structure, and therefore furniture filled with polyurethane foam is quite rigid.

- Sintepon - soft white synthetic material, most often used as insulation or as a cheap way to soften the surface.

- Batting- soft filler with a high content of cotton, and therefore it is a material that passes air well.

In addition, a spring block can be installed inside the sofa seat, which will extend the service life and improve the functional qualities of the furniture. The springs for such a block can be dependent and fastened to each other according to the serpentine principle, or they can be independent - in this embodiment, each spring exists separately and has its own individual case.

If the sofa is planned to be made sliding, it is necessary to purchase a layout mechanism. They exist in the following types:

- "book";

- "Eurobook";

- "tic-tac";

- "accordion";

- "roll-out";

- "dolphin";

- "konrad".

In addition, you need to stock up on self-tapping screws, wood glue, which will easily and firmly glue the wooden frame, you will definitely need dense threads for sewing upholstery details.

Of the tools, an electric jigsaw, a screwdriver, a furniture stapler, as well as a sharp knife for cutting foam rubber will be useful.

How to do at home?

Any home-made project must begin with an idea - choosing a model and determining the purposes for which this piece of furniture will be used. If the sofa is planned to be used as a main or additional bed, it is better to opt for a sliding model, in this regard, you need to take care of buying a layout mechanism, choosing a denser and higher-quality upholstery material, as well as using a full-fledged spring block at the base of the furniture. If the home-made sofa will be used strictly for sitting or as an element of the decor of a summer house, garden house or stand on a terrace, you can experiment with the materials of both the upholstery and, in principle, the entire sofa. Massive sofas made of timber, actual from pallets, unusual ones made of cardboard, with and without armrests - any option can be appropriate and successfully created with your own hands.

So, when the type of the future sofa is chosen, its purpose is indicated, the general plan is drawn, the dimensions are outlined, you can start purchasing materials and directly creating what you want.

Creating a sofa with your own hands includes the following steps:

- selection and purchase of materials;

- creating a frame;

- upholstery.

Of course, depending on the type of construction chosen, actions can be changed, added, or completely excluded.

From a pallet

So, in order to make a sofa out of pallets, you need the most minimal set of materials and tools. You will need several pallets, if desired, they can be sanded and painted in the desired color, a screwdriver, self-tapping screws and a jigsaw, plus pillow material that will serve as a soft back and seat for such a sofa. For armrests, it is necessary to cut off the extreme parts of the pallets with thick wooden inserts. These short parts must be stacked on top of each other and secured with screws, after which the finished armrests must be attached to the already prepared base. The best option is 3 cuts stacked on top of each other, but if desired, their number can be changed, which will help achieve the desired height of the armrests.

At the base there can be either one pallet or several interconnected with screws, the choice will depend on what size the sofa is planned to be in the end.

Next, use a sharp knife to cut out two rectangles from the foam rubber or other selected material to fit the size of the seat of the future sofa. After the foam has been successfully cut out, it is necessary to start tightening the seat. There are several ways here: the upholstery can be sewn with a machine or manually, as well as fixed with a furniture stapler. The same manipulations must be repeated in the manufacture of foam cushions for the back of the sofa.

If the sofa will stand against the wall, then here its manufacture can be completed, but if it is not intended to lean the sofa against the wall, then the backrest must be attached to the finished frame. To do this, you need to take one or two more pallets, depending on the amount used to make the seat, and screw it with self-tapping screws and a screwdriver to the back of the sofa, after which you can already install the pillows in place and enjoy the homemade new interior.

Homemade "book"

This is a more difficult option to manufacture, requiring more materials, time and effort. It is necessary to start manufacturing by determining the exact dimensions of the future interior element; for convenience, they must be written down on a sketch prepared in advance. In addition, you need to stock up on materials, you will need:

- boards 25-30 mm thick for the manufacture of the frame;

- beam;

- foam rubber;

- synthetic winterizer or batting;

- upholstery fabric;

- plywood;

- sofa legs;

- sofa mechanism;

- wooden slats;

- glue;

- self-tapping screws;

- staples for furniture stapler.

In addition to the above materials, you need to stock up on a certain set of tools. So, you will need:

- jigsaw or hacksaw;

- furniture stapler;

- screwdriver;

- roulette;

- pencil.

When you have all the listed materials and tools, you can start manufacturing. This production involves a fairly large amount of debris and dust, so all work is best done on a garden plot, street, or in a garage.

The first step is to assemble the frame of the future linen box, for this it is necessary to assemble a rectangle from the boards of the desired length (the length of the box is 30 cm, less than the final length of the sofa along with the armrests). After the main frame is assembled, it is necessary to strengthen it with transverse rails; as a base, a sheet of plywood is attached to the bottom of the frame using self-tapping screws. From boards of the same length, it is necessary to assemble two more rectangles with transverse reinforcing rails - these will be the seat and back frames of the future sofa. It is necessary to attach wooden lamellas to these frames using a screwdriver - the basis for the future mattress. It should be remembered that all lamellas must be located at an equal distance from each other.

The next stage is the manufacture of armrests. Four armrests of the selected size and shape are cut out of plywood, then a beam is installed along the perimeter to strengthen the structure on two copies, after which the two remaining forms are fixed on top of the beam. Further, the individual parts of the sofa frame are assembled into one whole, at the same stage a special layout mechanism is attached.

There are a few simple rules to help with assembly:

- When unfolded, the distance between the back and seat of the sofa should not be less than 1 cm;

- In the folded design, the seat should in no case protrude beyond the attached armrests.

Next, the finished frame is pasted over with foam rubber, which must be chosen based on personal preferences, since there is a different structure and thickness of the material. After foam rubber, for greater strength and softness of furniture, the frame is sheathed with padding polyester or batting. At this stage, the most creative part of the work begins. Using a sewing machine, you need to sew a cover from upholstery fabric. Such covers are usually sewn to fit the dimensions of the sofa parts and put on them, shrinkage occurs with the help of zippers.

An alternative to this method is to shoot the upholstery fabric directly to the frame using staples and a furniture stapler. This method allows you to attach the fabric exactly along the frame with less time. The sofa book is ready. All that remains is to install it in the most prominent place in the room, perhaps even building a special podium for it, because a hand-made thing should arouse the pride of the inhabitants and the envy of those who do not have such an exclusive piece of furniture.

New furniture from old

When at home there is an old sofa that has been sold and has become uncomfortable, but a favorite sofa that is a pity to throw away, you can create a new piece of furniture from it. First you need to remove the old upholstery, carefully so as not to tear, because in the future it will become a pattern for the new one. Next, remove the filler from the frame (foam rubber, polyurethane foam, or any other), if the bed is on a spring block, then remove it as well.

Clean off the remnants of the old filler from the frame and sand it with sandpaper - now the frame is completely new. This is followed by the replacement of springs, if required by the model of the sofa.

After the new spring block takes its place, it is necessary to return the filling to the sofa - the frame is pasted with foam sheets of the required size. The final stage of the transformation will be the upholstery of the sofa with new material. To do this, it is necessary to cut out the material according to the old pattern, sew the details, put the finished cover on the workpiece and shoot it with a furniture stapler. If desired, you can add a new thing with soft pillows made of suitable fabric.

Where to place?

The placement of a homemade sofa is determined by some factors, such as:

- Room style;

- Functional features of the piece of furniture itself;

- Owner's taste preferences.

So, a sofa made of pallets that is so relevant today will fit perfectly on a balcony or terrace, a comfortable stylish seat will enliven the interior and you will want to spend evenings in it more often, wrapped in a blanket and contemplating the stars in the sky. In addition, these sofas can be the highlight of a loft-style room.

A hand-made wooden swing sofa can be placed in a gazebo in the country, you just need to remember that since it will be influenced by natural factors, the wood used for manufacturing must be treated with a special protective impregnation. Folding, full-size sofas with linen boxes, created by yourself, can be placed in the bedroom or in the garden house, you just need to choose the right upholstery for manufacturing, which will look harmonious in the interior of the room.

Simple frameless non-folding sofas will be a great option for a kitchen or living room, especially if such a sofa has an angular shape. Here it is necessary to pay special attention to the selection of fabric - it should not absorb odors and be picky about cleaning. You can also treat the upholstery with a special coating that will repel water and reduce the combustibility of the material. In addition, in the guest room or on the loggia, you can also place furniture made by yourself from cardboard. However, it is worth remembering that such models are sensitive to moisture and do not accept wet cleaning or liquids on them.

However, if the sofa is already created by oneself, there is definitely no need to hide it, it is safely necessary to place it in the most prominent place in the room, unless, of course, materials suitable for the general interior of the room were used when creating it.

First of all, it is necessary to develop a detailed project of the future sofa. The definition of overall dimensions, the exact height of the backrest, armrests, seat depth and other important elements should be reflected on the plan. It would be great if it would exist both in written and electronic form. When determining the dimensions, it must be remembered that, for example, the height of the seating area directly depends on the location of the furniture, and the kitchen corners are usually somewhat higher than those pieces of furniture that are used for relaxation. When a plan is developed, attention can be paid to materials. To create a frame, experts advise paying attention to wooden beams or cuts of a profile furniture pipe. With it, the frame will turn out to be even more durable, and the sofa will last a long time.

If foam rubber was chosen for internal filling, it is necessary to choose not loose and sufficiently thick cuts. The thickness ideal for home-made furniture starts from 15 cm, otherwise the foam rubber will need to be replaced too quickly, for which you will have to disassemble the entire structure. The same rule applies to the restoration of old furniture. As for the reworking of old furniture, the main parting word here will be that the sofa must be photographed before disassembly, plus, photos of the disassembly process itself will be useful - this simple action will help to assemble a new similar item in the future, and not guess what and where it is attached.

If the idea to assemble a sofa on your own comes for the first time and there is no experience in this, you should not chase complex designs, it is better to start with the simplest straight forms. And in order to feel the wood, tools and fabric, it’s better to start with an ordinary stool, so to speak, to test your strength on it. After all, it is better, in which case, to remake a smaller form than large-sized furniture.

Typical furniture does not always fit a particular interior. When the standard options do not fit into the situation, you can make a sofa with your own hands - after all, any craftsman will cope with the work. To do this, you need drawings, materials, step-by-step instructions. The product, assembled independently, will last a long time, and will also look interesting in the room.

Work at home should begin with the creation of a scheme. To make the correct drawing of the sofa, you must:

- Select a transformation mechanism.

- Decide on the dimensions of the finished product, depending on its purpose (for sleeping or relaxing), as well as the area of \u200b\u200bthe room in which home-made furniture will stand.

- Choose a model that suits the shape and design.

- Prepare everything you need for work.

When choosing or independently constructing a drawing, it is important to take into account the characteristics of the specific material from which the home master plans to make homemade sofas. When the scheme is ready, you can proceed to the next stage - the calculation and ordering of metal, wood (or plywood, laminated chipboard), filler, upholstery fabric, consumables.

Upholstered furniture of a standard type consists of two blocks - a back and a seat. When unfolded, these components form a sleeping place. A corner sofa made of plywood is a design of three modules interconnected in the form of the letter G (less often - P). The furniture stands on four legs, in some models rollers are used instead.

If the product is intended for rest and night sleep (for example, for a bedroom or a nursery), a niche for bedding may be provided in the design. It is also convenient to put children's toys or old, unnecessary things in such a box. The presence of a special box makes the furniture more functional, but increases the weight of the sofa, making it difficult to transport.

Before studying the drawings and diagrams, you need to decide on the dimensions. The standard dimensions of the product with the book mechanism are 140 x 220 cm when unfolded. When the furniture is assembled, these dimensions are reduced (100 x 220 cm).

First, individual parts (modules) of the product are made, and then they are combined into a single whole. Assembling the sofa is the most important stage. When connecting the two main elements together, the master must ensure that the folded seat does not extend beyond the armrests. When the sofa is laid out, the distance between the frames should not be less than 10 mm.

The back and seat are made from blanks. Their number is the same for any model. It is necessary to cut out:

- rack;

- top and bottom rails;

- side bars;

- overlays.

You will also need two crossbars for the seat - back and front. For manufacturing, a board of 50 mm is suitable. Lastly, blanks are made for the back and seat panel.

Training

For sleep and relaxation

Materials and tools

For the manufacture of the frame, wood is most often used. Less expensive options are also possible - plywood or chipboard. Metal frames are the strongest, but they have one drawback - the large weight of the finished product. Experienced craftsmen take for work such types of wood as:

- pine;

- Birch;

- alder.

When choosing a drawing, you should pay attention to the fact that each scheme is designed for specific materials. A drawing of a metal frame is not suitable for those who decide to make a sofa out of wood, and vice versa. For additional rigidity, experts recommend using a crate made of wood, plywood or chipboard. It can be made independently or replaced with lamellas of industrial production.

For upholstery, it is recommended to choose velor, tapestry or jacquard. These fabrics are stain resistant and easy to care for. The most popular fillers are batting, synthetic winterizer and pressed felt. They differ in elasticity and high density. Sintepon is a cheap option, but it does not last long.

You should prepare in advance the tools necessary for assembling the product at home. First of all, it is a furniture stapler (for upholstery) and a screwdriver. The master will also need:

- ruler;

- wooden or metal square;

- stationery knife-cutter;

- miter box.

It should be purchased in advance and diluted according to the instructions for carpentry glue and for foam rubber. You will also need consumables: self-tapping screws, wood screws, nails, staples. After that, you can start working.

In Soviet times, foam rubber was most often used as a filler for upholstered furniture. It does not last long and can cause an allergic reaction. When hauling old sofas at home, foam rubber is usually additionally compacted with padding polyester.

Beam solid wood

Chipboard sheets

Fillers

Upholstery materials

Tools for the job

Choice of transformation mechanism

It is necessary to choose high-quality parts from good metal that can withstand heavy loads. Each mechanism has its pros and cons. They are presented in the table below.

| Name | How it works | Advantages and disadvantages |

| Book | Two frames with fixed spring blocks are responsible for the transformation, instead of which a soft filler can be used. | The backrest is easy to recline, below you can put a box for storing bedding. However, such a sofa is difficult to decompose if there is not enough space in the room. |

| Tango | The principle of operation is similar to a book, but the back of a corner sofa (or a standard-shaped product) can be in three positions: horizontal, vertical and intermediate. | The furniture has a compact size, when unfolded on the sleeping surface there are no bumps, but the back cannot be leaned against the wall. |

| Eurobook | The seat rolls forward thanks to small rollers, the back is hidden in a special niche. | The mechanism lasts a long time, the bed takes up a large area, but the rollers can leave scratches on the linoleum. |

Most often, in home-made products, the book mechanism is used. It is easier to make it from improvised materials. If the spring blocks are made from high-quality raw materials, they do not wear out for a long time. A more modern modification of this model is do-it-yourself eurobook sofas.

The French folding bed mechanism is very popular among lovers of transforming sofas. To expand the bed, just pull the edge of the seat, and the three sections of the product will straighten out. However, this option is not suitable for home-made furniture, because such a mechanism quickly fails.

If the room in which the sofa will be made of wood is spacious enough, you can use the accordion mechanism. Such a product takes up very little space when folded, but requires a lot of space for unfolding. When the bed is pulled forward, it rests on the outgoing legs. The main advantage is that no physical effort is required for unfolding.

Accordion sofas last a long time, but moving legs can scratch the flooring. They also have nowhere to build a box for bedding, and the niche is located in the area of \u200b\u200bthe rear back, which is not very convenient.

Eurobook

French cot

Accordion

Manufacturing steps based on the model

A step-by-step guide to making furniture for sleeping and relaxing may vary depending on the specific model. Most often, home craftsmen make classic books, corners and modular products from pallets. Each option has its own design features. Instructions for assembling sofas depend on them.

Sofa book

For work, you will need timber and boards, foam rubber as a filler and upholstery fabric. You also need a ready-made transformation mechanism. Consumables will require nuts, screws, furniture bolts, staples. Below is a step by step guide. Necessary:

- Assemble a laundry box from boards measuring 1900 mm. Strengthen the finished product with 2 rails.

- Make two frames - for the seat and back, fix the slats on them to support the mattress.

- Cut out armrests from fiberboard. Use boards 55 mm wide and 1 m long.

- Make a wooden frame for the armrests and assemble the parts into one whole.

- Drill holes in the bedding drawer.

- Assemble a sofa book from modules.

When installing the transformation mechanism, it must be ensured that in a horizontal position the distance between the backrest and the seat is about 10 mm. To strengthen the structure, you can additionally apply a grid of rails. The frame is sheathed with sheets of foam rubber. To smooth out sharp corners along the edge of the product, it is recommended to glue an additional strip of the specified material as a border. If everything is done correctly, you should get a soft roller. The sofa the book differs in compactness and convenience, has interesting design.

We collect a box for linen from the boards

We strengthen with slats

We assemble the frame for the seat and back

Mattress support slats

We cut out the armrests

armrest frame

Drilling holes in the drawer

Assembling the modules

We sheathe with foam rubber

We soften the armrests with foam rollers

Do-it-yourself sofa book is ready

Angular

For work you will need timber and boards. You should also pre-select plywood or chipboard. The first option is more durable and reliable, the second is cheap. The minimum recommended chipboard thickness is 16 mm, it makes no sense to take thinner material. Stages of work:

- Draw a drawing. Calculate the length of both modules.

- Draw up a diagram showing the locations of the fasteners.

- Assemble and fasten with self-tapping screws a rectangular frame of boards.

- Install the cross bars in the center of the lower and upper parts.

- Sew up fiberboard at the bottom of the box.

- In the described way, make the second half of the product, the corner insert of a square handicap.

- Fold and fasten the three received elements.

- Make a back of 6 modules, fasten all the parts to each other with a beam.

- Install the seat on the hinges attached to the backrest components.

- Fill upholstered furniture with foam rubber at least 10 cm thick.

- Sheathe the frame with upholstery fabric.

For upholstery you will need a furniture stapler. It is recommended to start sheathing from the farthest corner of upholstered furniture, gradually moving to the center. You need to nail the fabric to the back from the bottom up. When this part is already processed, go to the sides. Lastly, the seat is covered with fabric.

Mounting layout

We collect the frame from the boards

Sew up the bottom of the fiberboard box

Installing cross bars

We assemble the back

Connecting the back and seat

We stuff with foam rubber

Sheathe with batting

We assemble and glue the corner insert with batting

We sheathe the back

We nail the matter to the sides

Covered with upholstery fabric

Do-it-yourself corner sofa

Pallets are wooden pallets. You can find them at any hardware store. Craftsmen use pallets as modules in the manufacture of upholstered and cabinet furniture at home. To make original sofas with your own hands for a summer residence, you will need one large pallet. To work you need:

- Saw the pallet into 2 fragments - large (seat) and small (back).

- Attach the legs to the seat with screws.

- Fix the back in the desired position. To do this, you need wooden corners.

- Prime and varnish the surface of the furniture.

- Fasten the plywood for the back to the crossbars using the hinges.

If the product will stand in the country or on the balcony, it is best to sew a protective cover and decorative pillows from leatherette. This material is unpretentious in care. Also, leatherette tolerates high humidity well and has a long service life.

To make a product of standard sizes, suitable for sleeping and relaxing, you will need 6-8 pallets. Manufacturing technology will be about the same. One of the pallets needs to be disassembled into boards and used to fasten the modules to each other. Before you start sleeping on such furniture, it is advisable to lay an orthopedic mattress.

Saw the pallet into two fragments

Installing the back

We fix the back

We prime the surface

Fasten the legs with screws

We sew a cover and fill it with upholstery

Finished pallet sofa

To make a soft sofa, it is recommended to choose functional models with drawers and good quality filler. Roll-out (retractable) options with rollers and guides are very popular. They are good because they do not require physical effort to unfold.

You should not save on fittings, because the life of the furniture depends on the reliability of fasteners. Novice joiners and carpenters are better off choosing clear geometric models. They are suitable for interiors in any style. They are also much easier to make clearly and accurately compared to furniture of complex shapes.

Spike joints located at the ends of the boards increase the strength of the product and increase its service life. However, it is impossible to make them at home, this requires special equipment. For this reason, a novice carpenter should not set himself such a task.

Experts do not advise connecting individual elements with nails. Instead, experienced craftsmen use screws or self-tapping screws. If nails are used, the fasteners are gradually loosened.

Recommended wood species for making a sofa at home are spruce and pine. Before work, the boards are carefully polished - the surface of the material must be smooth, without roughness. Do not cut boards indoors, as wood dust accumulated in the air is harmful to health and can cause allergies.

For stuffing the back, you need to use thin foam rubber, for the seat - more dense. You can glue several sheets together. It is necessary to pay attention to the density of joining of soft parts with each other. A thin layer of synthetic winterizer is laid on top of the foam rubber to protect the filler from external influences. In furniture factories, it is used to make sofas softer.

The frame must support the weight of several people. A children's sofa made of timber is calculated based on the weight of babies (teenagers), an adult - depending on the build of older family members.

In order for wood or chipboard products to serve for a long time, all parts must be treated with a special furniture varnish (stain). If the garden sofa is intended for children to relax, the coating should not contain aggressive and allergenic chemicals. Homemade sofas have many advantages. They fit well into any space, look unusual, suitable for sleeping and relaxing. The main thing is to choose high-quality material for work and clearly present the step-by-step sequence of actions. Then making upholstered furniture with your own hands will become an interesting hobby.

Withdrawable

Children's sofa in the interior

Sofa made of pallets treated with stain

Video

Independent production of upholstered furniture for the home can provide a lot of advantages and opportunities for creating an original design and individual parameters of home interior items. The finished product will not only become the pride of independent work, but will also allow you to accurately enter the dimensions of the furniture in any room and show your own design talent, but before direct work, how to make a sofa with your own hands.

Creating furniture with your own hands is a feasible task for everyone who knows how to use tools and is ready to be patient. A little perseverance, hard work and imagination will help create an original masterpiece that will serve for many years and delight the eye every day.

A cozy home is hard to imagine without beautiful upholstered furniture. Therefore, the sofa often occupies a dominant position in the home interior. A lot of time is spent on it: games with children, sleep, gatherings with friends and much more. To create your own sofa, you first need to figure out which design will best suit the needs of the family.

To understand how to make a sofa with your own hands, you need to study their varieties. Among the variety of types of upholstered furniture, there are several most popular models:

- Book. This design allows you to fold a homemade sofa in one motion, but it is quite difficult to assemble the frame correctly, in addition, you will need welding and assembling a special mechanism.

- Dolphin. This is a more modern version of the design, but it is quite difficult to assemble it. Unfolding occurs due to the extension of the lower section and when covering it with a folding back.

- Pull-out system. Such a device allows you to create a high-quality, even surface for sleeping and facilitates the transformation process.

sofa dolphin

- Corner sofa. One of the most popular models. The corners fit perfectly into any interior, allow you to use more usable space and provide a comfortable sleeping place.

- Ottoman. The simplest design. These sofas do not fold out, so the assembly of the frame will be very simple.

When choosing the future design of the sofa, it is worth considering the place where it will stand and the purpose of its use. Before starting work, you need to accurately measure, provide for how many people will sit on it, if this is a future bed - consider the height of a person, think through all the details, make preliminary drawings, and only then start work.

Do-it-yourself corner sofa

To make a high-quality corner sofa with your own hands, you need to make an effort, but the result is worth it. After all, the future interior object will save more than half the cost of the finished products of stores, harmoniously fit into the space of the dwelling, make it possible to place bed linen and other household items in niches, and when assembled, it will economically spend space.

Also, do not forget that the corner sofa has a more prestigious look than a simple folding option, and if you do not skimp on high-quality materials, the result will delight for many years.

In order not to be disappointed in your own idea and avoid banal mistakes, you should follow some simple rules:

- if the work is being done for the first time, then you need to choose the simplest drawing, without additional shelves and tables;

- discard spiked joints, such work can only be done qualitatively by a professional carpenter;

- develop or select among the existing ones a simple drawing for a handmade corner sofa with an indication of all elements, dimensions and movable components of the structure;

- do not connect the parts with nails, over time they become loose and the structure falls apart, and self-tapping screws can strengthen the wood frame for many years;

- when choosing wood, preference is given to conifers, they are more durable, have a rich fibrous structure and prevent moths from appearing in furniture;

- all structural parts to be joined must be glued, but before this procedure, make sure that the joint is assembled correctly and all elements are docked as needed;

- wooden parts made by hand must be carefully sanded to give the material greater strength and safe work with the product.

Material selection

For the first time, a do-it-yourself corner sofa should be made from materials that are not the most expensive category. This will not spoil the final product, but will help to understand the intricacies of the work and avoid excessive costs.

To create a corner sofa, you need to purchase at a hardware store:

- pine timber 30 by 50 mm;

- fiberboard panels 3 mm;

- chipboard panels 16 mm;

- plywood sheets of 5 and 15 mm;

- lifting mechanism or microlift;

- 9 legs for furniture;

- dense sheets of foam rubber 20 and 40 mm;

- dense material for furniture upholstery;

- filler for upholstery and pillows of your choice.

To complete all the work, you must have the following tools available:

- jigsaw (work can also be done with a hacksaw, but the edges may turn out to be uneven);

- drill with a set of drills;

- screwdriver;

- a knife with a sharp blade for cutting foam rubber;

- several types of fastening: nails, self-tapping screws, screws;

- PVA glue for gluing foam rubber and carpentry glue for joints;

- sewing machine for creating upholstery, covers and pillows.

Before starting work, consider how the parts will be cut. If the area of \u200b\u200bthe room does not allow high-quality measurements and cuts, then you should entrust this work to professionals. Most hardware stores and building materials stores offer similar services.

Frame assembly

To start the assembly, you need to clearly imagine how to assemble the sofa, pre-mark the details on the chipboard sheets, according to the drawing and the selected dimensions. Then cut them out, correcting all the irregularities, and fitting the size of the parts to each other. Among the resulting blanks should be:

- Frame. This is the simplest part on which the rest of the structure will be attached.

- Armrests. For full-fledged furniture, you will need two identical armrests. It is necessary to assemble them in accordance with the drawings, attaching small parts to larger ones in descending order of size.

- Seats. It is preferable to assemble the seats, like the sofa itself, in parts. First one part, then the second. When assembling the seats, special attention should be paid to checking the coincidence of the diagonals of the boxes, so the correct shape will be created and the frame will become stable.

- Back. Having built a frame according to the drawing, you can connect the parts and attach the back to the sofa. Also, in the part with the linen box, you need to fix the bottom.

The frame of the sofa must be assembled with special care, since the stability, strength and durability of future furniture depend on it.

Foam covering

Before starting the sheathing, it is necessary to check the stability of the joints, they should not move, the fastening should be rigid. For foam sheathing, you need to take measurements from all surfaces. Each element is cut out separately and glued to the surface, after which the next element is measured. Each next part is joined with the previous glued elements.

The work must be done gradually, carefully trimming the patterns. Trimmings can be used for joints and small parts. For seats, you need to lay a thick layer of foam rubber, at least 100 mm.

If this is not available, then several layers of thinner material must first be glued together. The future comfort of the seats depends on the quality of this work. After finishing work, check the tightness of the upholstery and cover all hard and pointed parts of the body.

fabric upholstery

Initially, for sheathing, you need to choose a quality fabric. It is the upholstery fabric that determines the final appearance of the finished furniture. The widest range of modern textile stores are able to offer a wide variety of fabric options, both natural and synthetic.

Among the most popular types of upholstery fabric for a sofa, it is better to choose from the following types of textiles:

- Tapestry. This is an elite type of upholstery. The strength of the threads and the special weaving structure not only makes it possible to give strength to the material, but also to create an incredible pattern and texture.

- Jacquard. Premium material with a silky sheen and depth of texture. But this option is less wear-resistant and does not respond well to chemical and mechanical cleaning.

- Gunny. Budget solution for sofa upholstery. Pairwise weaving of threads resembles burlap. The material is pleasant to the touch and resistant to abrasion.

- Velours. Artificial velor is quite cheap, but there are also expensive natural varieties. The front side of the material resembles soft suede and can convey original patterns.

- Flock. Fabric with dense application of pile. This option is suitable for pet owners, because it is durable and not afraid of claws.

- Synthetic leather. Very durable material with a luxurious appearance. It is effective to use it in the lining of armrests and elements subject to increased friction. The disadvantage of the material can be considered a not very pleasant surface for contact with open parts of the body, especially in hot weather.

It is very important to remember that the combination of two or even three fabrics will make the product more original. It is enough to choose the right combination of fabrics and the result will be amazing.

For a smooth and neat sheathing, you need to perform the work in the following order:

- make templates for all the details from newspapers and check their coincidence by attaching the templates to a sofa upholstered with foam rubber;

- then, along the patterns on the wrong side of the fabric, borders are drawn and details are cut out with a margin of 1 cm or more;

- symmetrical ties on the sofa make the appearance more harmonious, and save the finished product from the folds that form during operation;

- in order for fabric tighteners to hold well and have an aesthetic appearance, you need to fasten buttons or loops through pre-made holes on the body plates;

- so that the foam rubber crumbles less, a layer of agrotextile should be laid between it and the upholstery fabric;

- fastening of fabrics is carried out with a construction stapler: first one side is attached, then the fabric is straightened, stretched and attached to the opposite side, then the edges are tucked in.

After completing all the operations, you need to assemble the sofa again. For a harmonious look, pillows or decor in the form of bundles, tassels and stitches are added. Legs and wood lining are attached last. In this form, a do-it-yourself corner sofa will last for many years and will delight the eyes of guests and households.

A little practice and diligence will help turn this hobby into an additional income for the production of custom-made furniture.

If not, then making upholstered furniture with your own hands will help save a lot on updating the furniture set at home, in the country or as a gift to relatives.

What else to read

THE LAST NOTES

- Amber extraction method in Belarus

- “Soon products from amber will arrive on store shelves”: trial amber mining has begun in the Brest region

- How to open an IP in Belarus

- Is it necessary to pay contributions to the social security budget for an employee who is on unpaid leave?

- What to give a man after parting